Tunnel bottom structure and construction method capable of eliminating uplifts of inverted arches of tunnel in area with high ground pressure

A construction method and high ground pressure technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of unfavorable tunnel bottom structure and unfavorable ground stress dissipation, and achieve the elimination of hidden safety hazards, remarkable economic and environmental protection, and convenient and compact construction procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

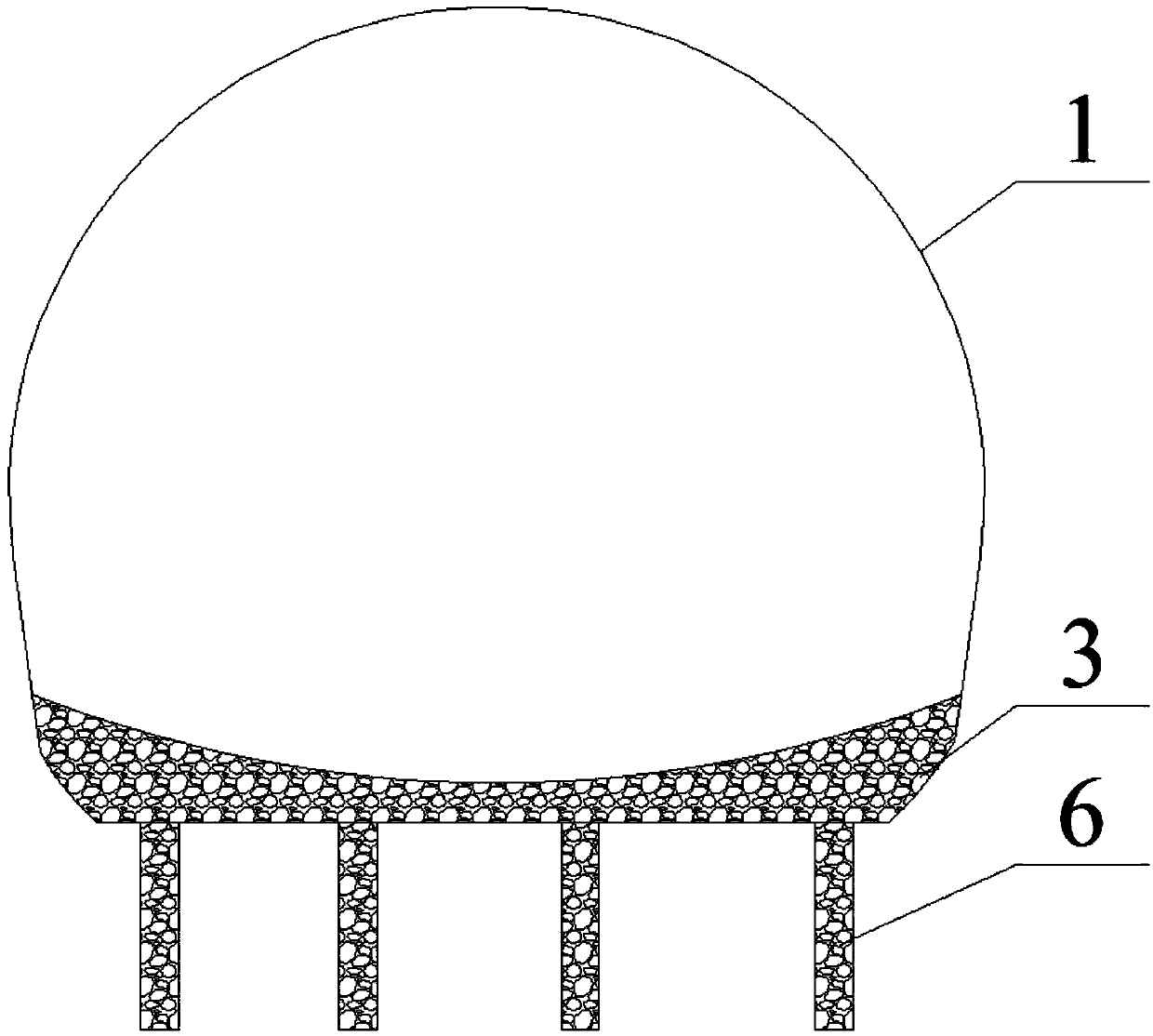

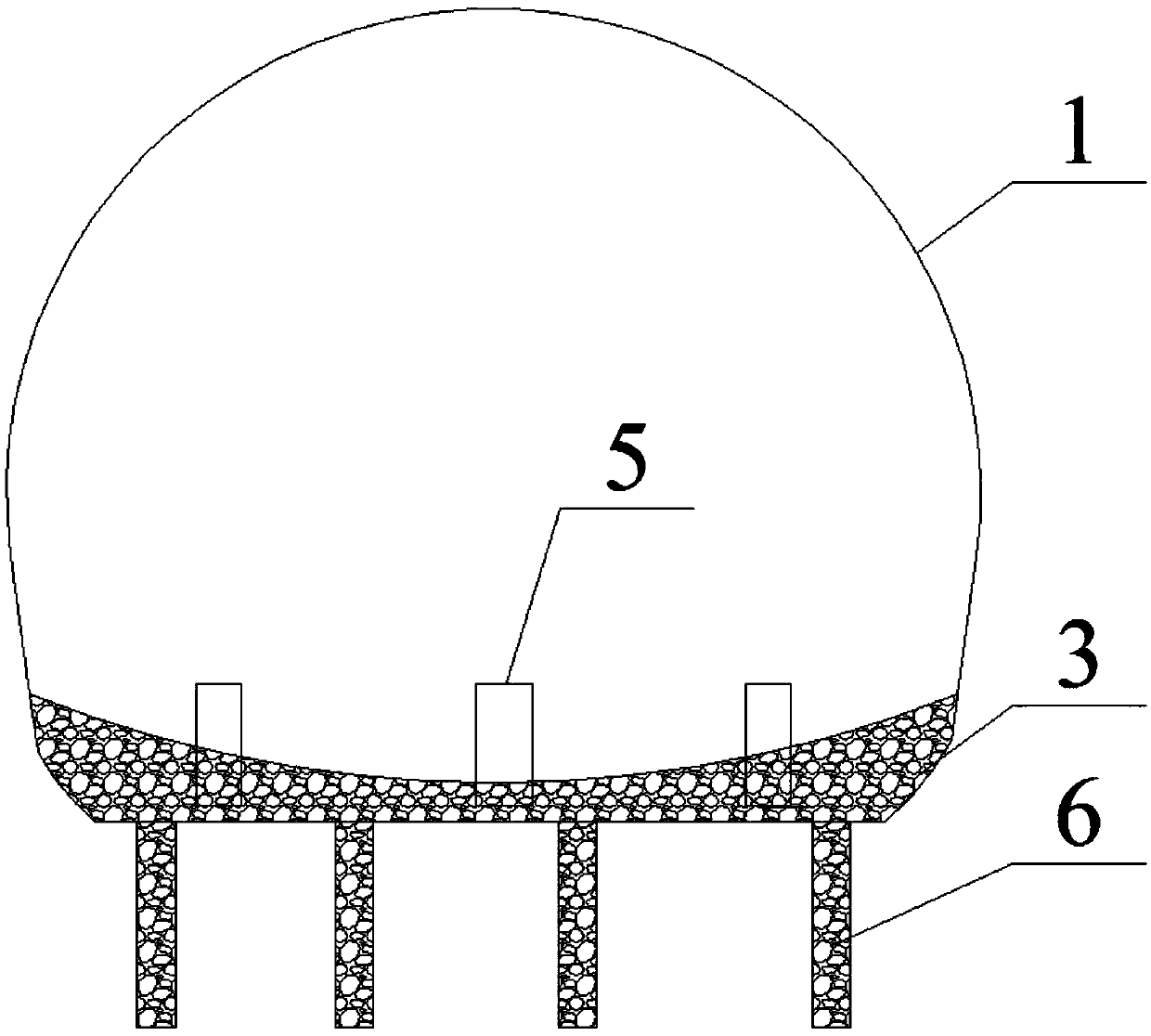

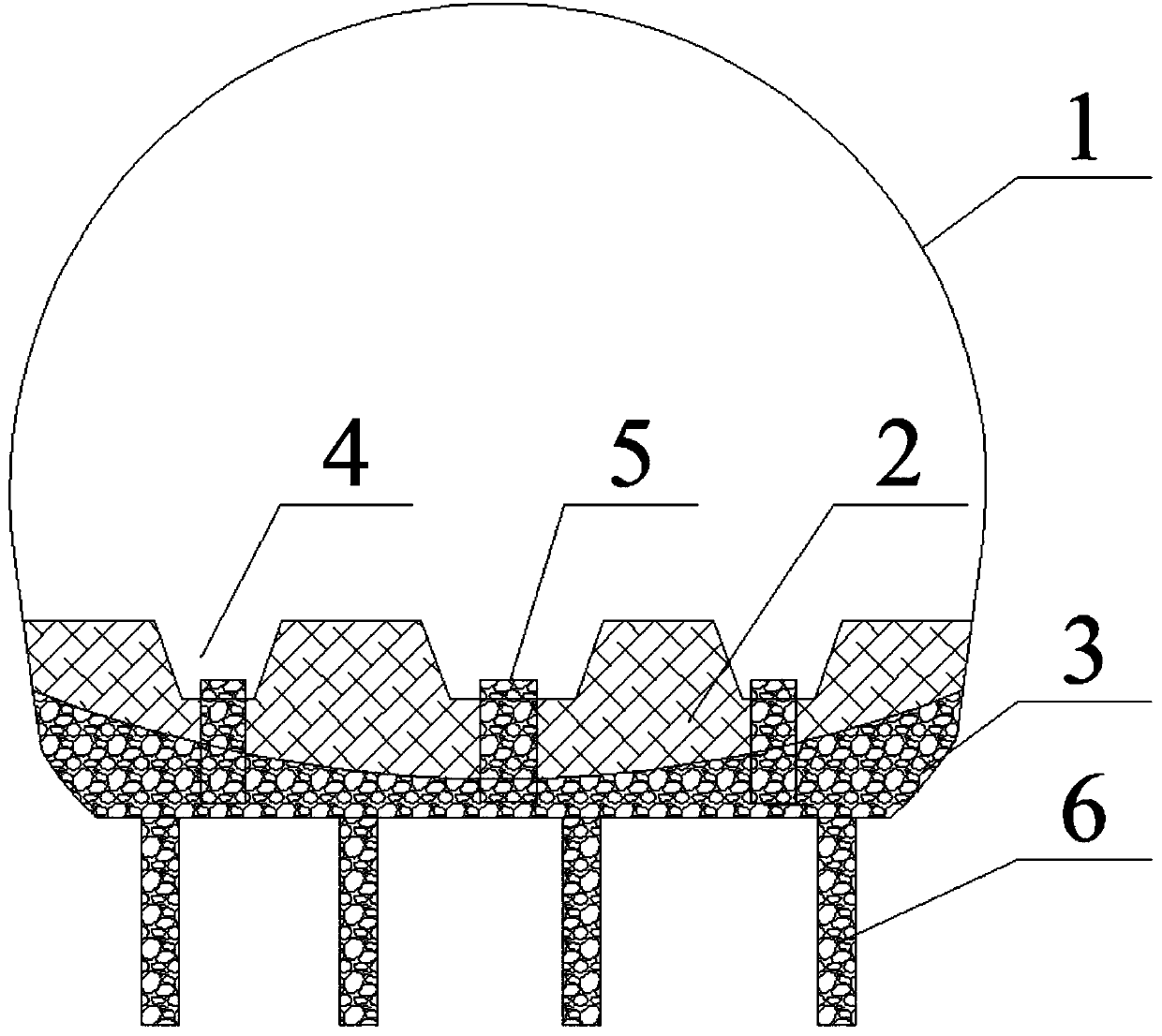

[0028] Such as Figure 1~3 , a tunnel bottom structure that eliminates the uplift of the tunnel invert in the high ground pressure area. After the initial support 1 of the tunnel is completed, excavate below the design area of the invert 2, and excavate 40-60 cm downward to form an over-excavation backfill area. This part of the over-excavation backfill area is used to backfill gravel to form an over-excavation backfill layer 3. A support layer with many pores can be prepared by filling gravel. The pore structure can effectively dissipate the ground stress. In addition, the pore structure can discharge groundwater through capillary phenomenon. Avoid excessive water pressure and damage to the inverted arch 2.

[0029] In order to quickly discharge the groundwater in the surrounding rock below the tunnel bottom, the present embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com