Constant flow valve and working method thereof

A constant flow, valve technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problem of water output exceeding the actual demand, unable to achieve fine adjustment, wasting water resources, etc., to overcome water pressure fluctuations and promote conservation And the effect of rational utilization and maintenance of water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

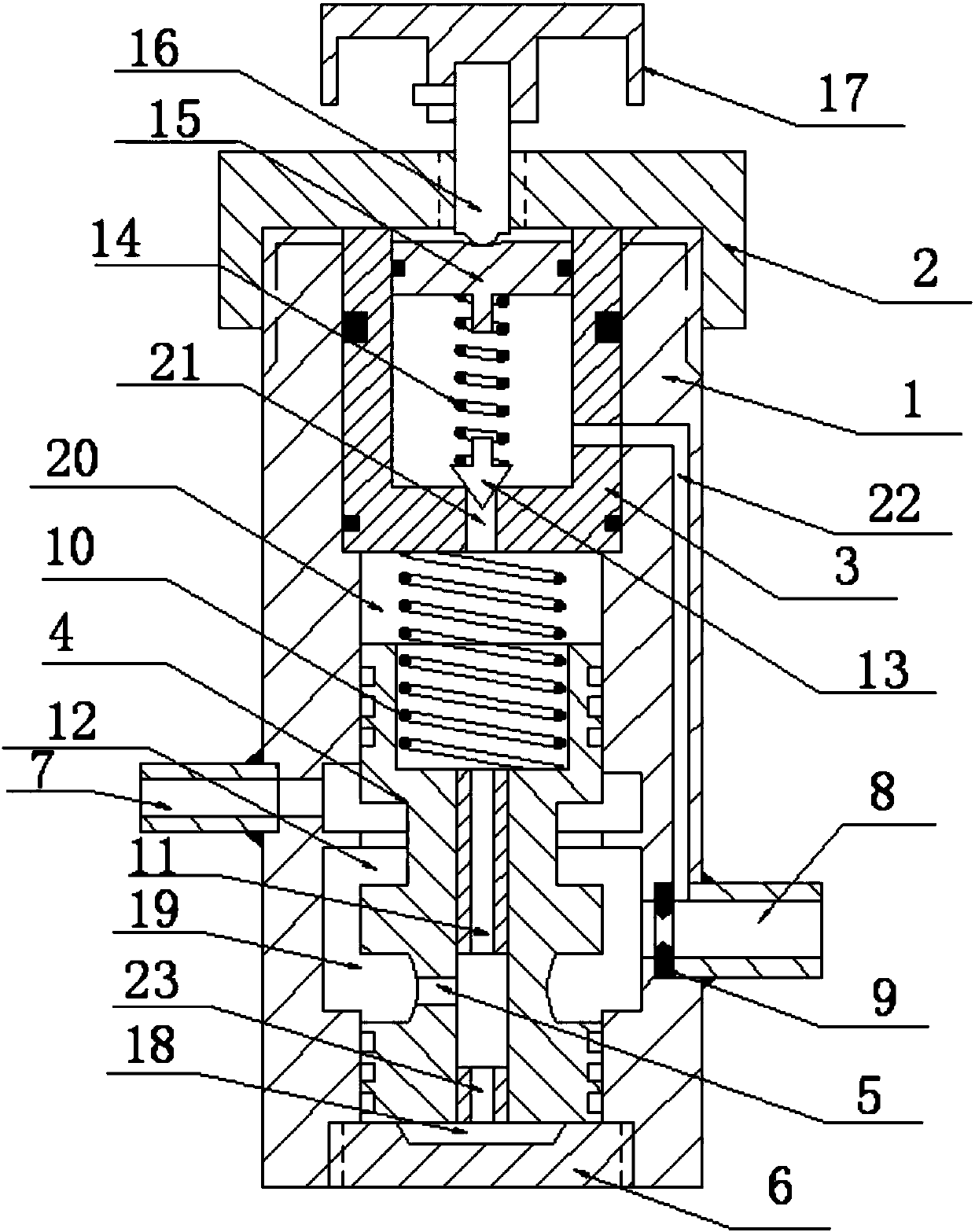

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0021] like figure 1 As shown in the figure, a constant flow valve of the present invention includes a valve body 1, an upper valve seat 3, a valve core 4, a water inlet pipe 7 and a water outlet pipe 8; The upper locking nut 2 is locked and fixed, and the lower part of the valve body 1 is locked and fixed by the lower locking nut 6 at the bottom; In the main spring 10, a lower valve cavity 19 is set between the lower part of the valve core 4 and the lower part of the valve body, and a back pressure cavity 18 is set between the bottom of the valve core 4 and the lower locking nut 6; the water inlet pipe 7 and the water outlet pipe 8 are respectively arranged in the valve body On both sides of 1, the water inlet pipe 7 is connected to the water outlet pipe 8 through the lower valve chamber 19, and the valve body 1 in front of the water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com