Charging-free acid extraction apparatus and acid extraction method for AGM storage battery

A storage battery, charging-free technology, applied to battery components, circuits, electrical components, etc., can solve the problems of short acid pumping time, time-consuming, waste of energy, etc., and achieve the effect of short acid pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

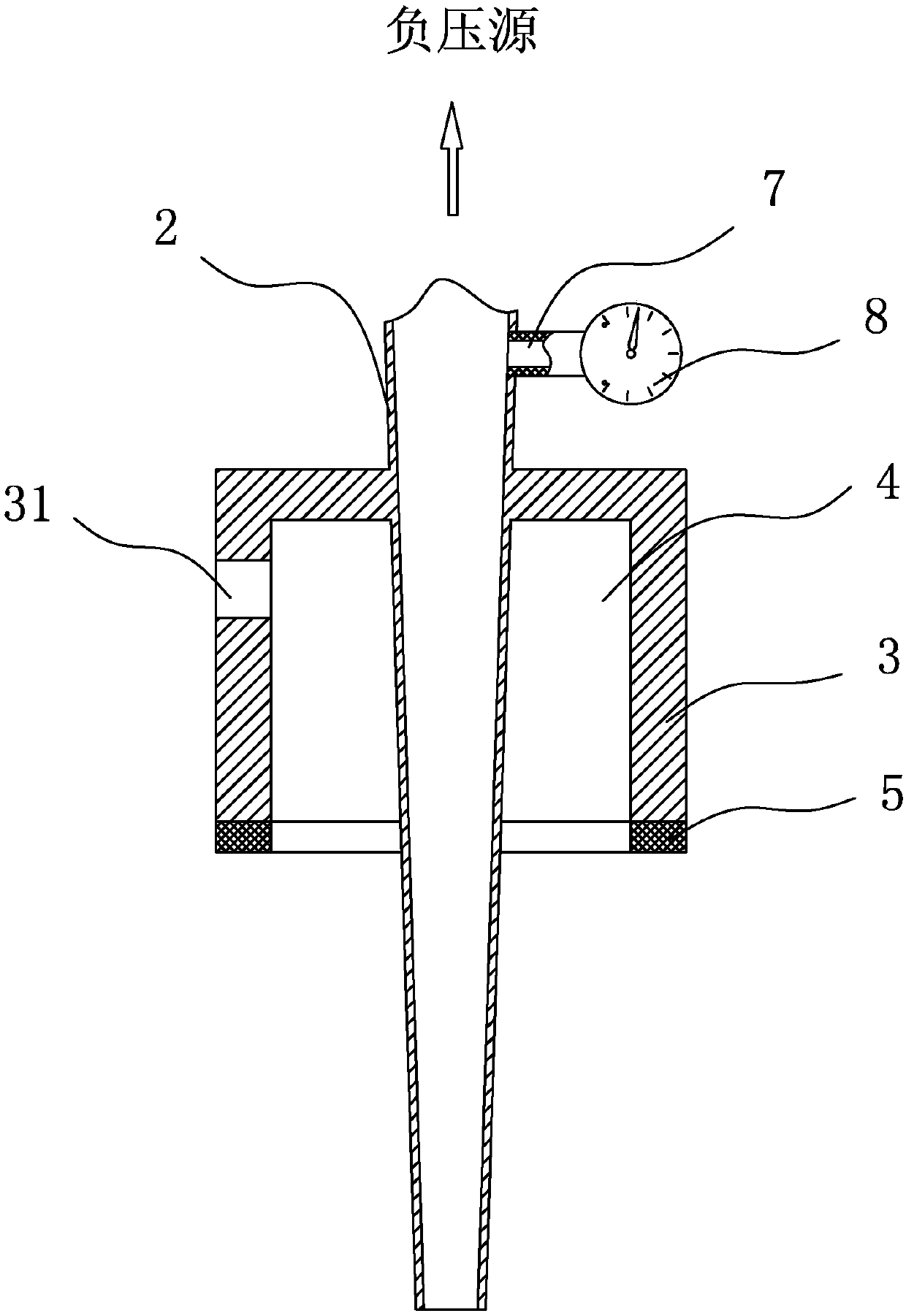

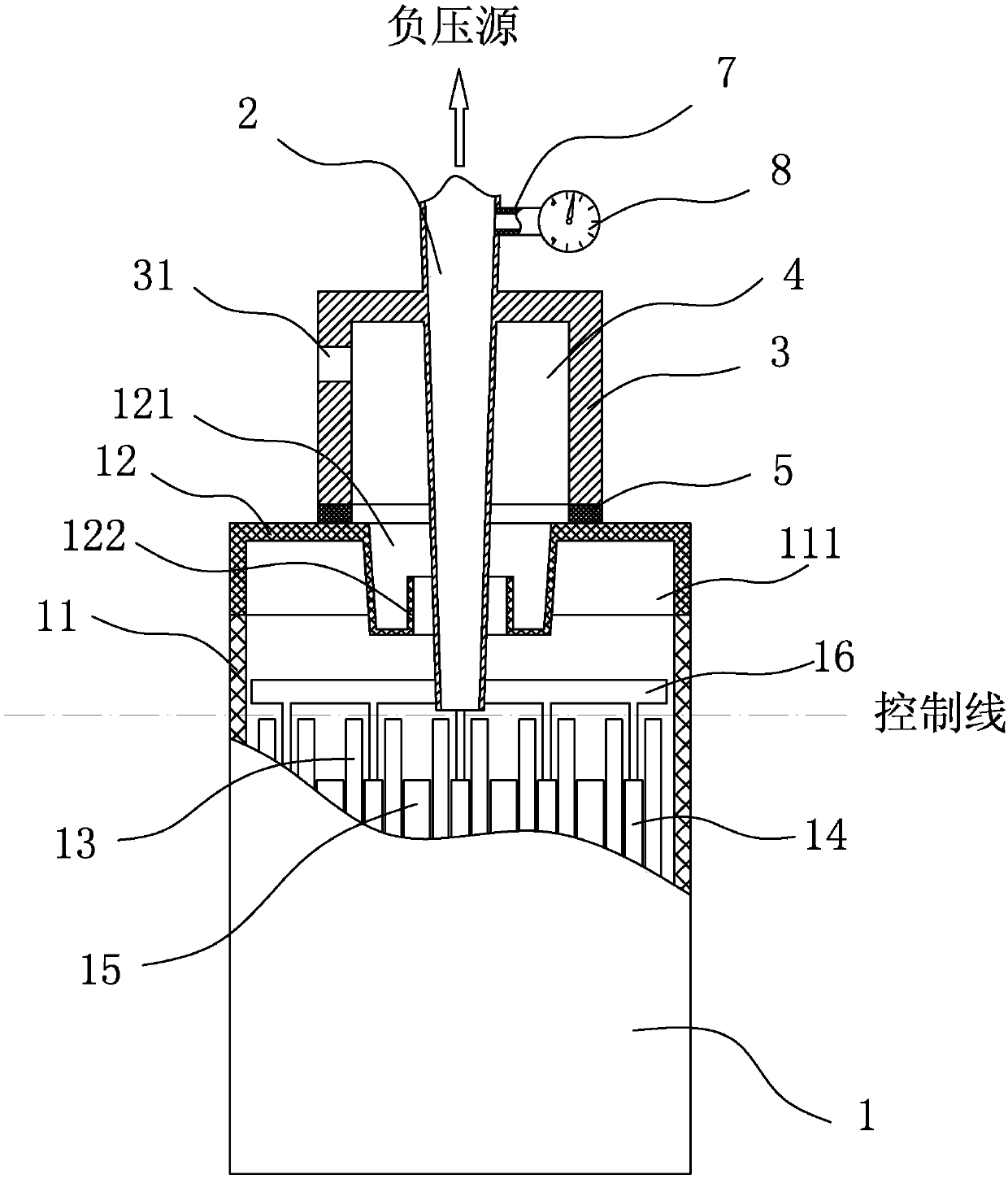

[0022] Embodiment 1: a kind of AGM storage battery charge-free acid pumping device of the present embodiment 1, such as image 3 As shown, the battery 1 includes a battery tank 11, a battery cover 12, and AGM separators 13, negative plates 14, positive plates 15 and corresponding busbars 16 placed in the battery tank and arranged at intervals. The battery cover is designed with concave holes 121 , the bottom of the concave hole is designed with a valve seat 122, such as figure 1 As shown, the acid pumping device includes an acid pumping tube 2 and an acid pumping cap 3 with an integrated structure. The lower end of the acid pipe can be inserted into the valve seat and enter the battery tank. The upper part of the acid pipe is designed with a process pipe. One end of the process pipe communicates with the acid pipe, and the other end is connected to a negative pressure gauge. The acid cap is open at one end. Thin-walled trough-shaped structure, the acid pumping tube is perpend...

Embodiment 2

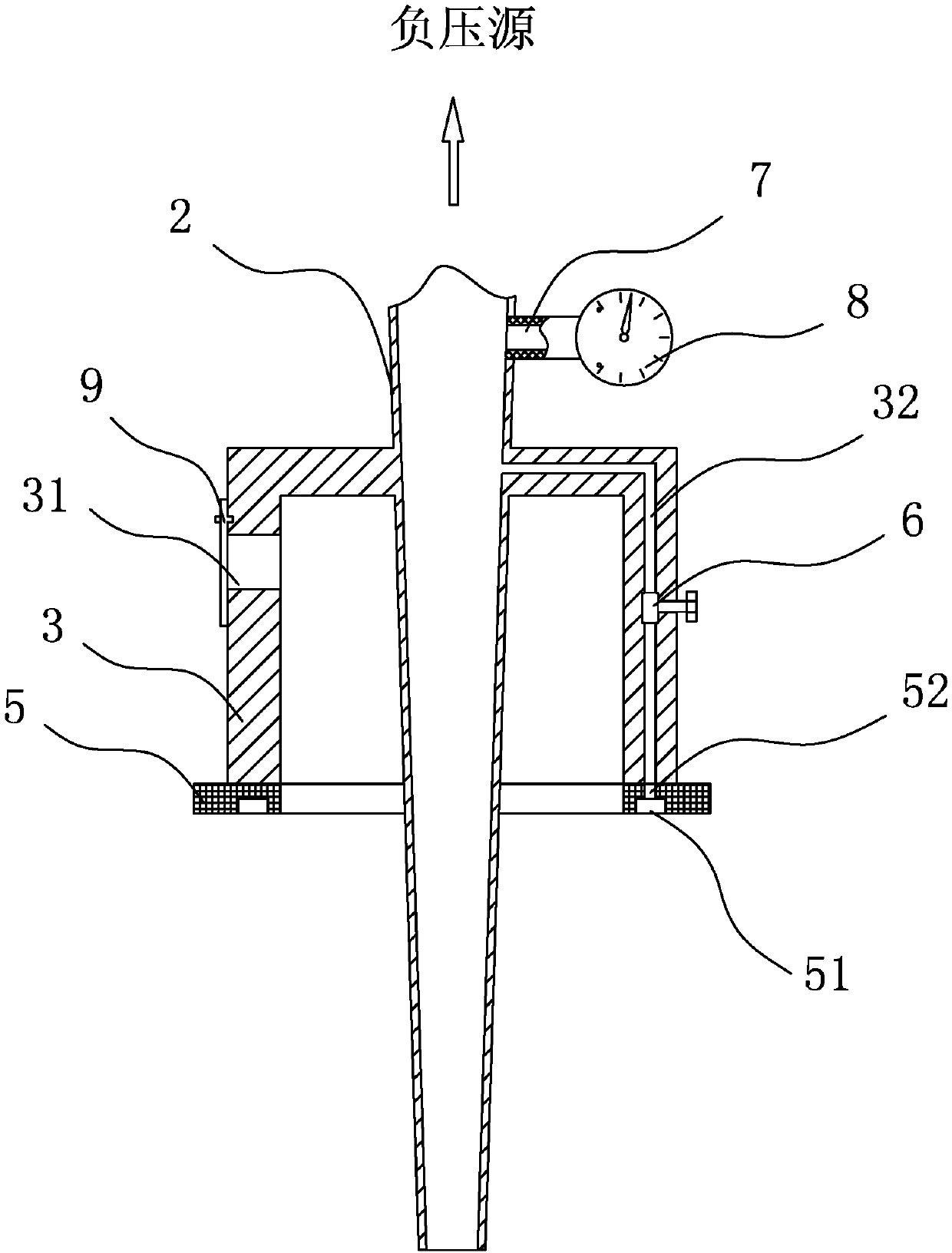

[0028] Embodiment 2: a kind of AGM storage battery charge-free acid pumping device of the present embodiment 2, comprises the acid pumping pipe and the acid pumping cap of integral structure, such as figure 2As shown, a negative pressure channel 32 is designed inside the side wall of the acid pumping cap, the lower end opening of the negative pressure channel is located on the end face of the notch of the acid pumping cap, and the upper end of the negative pressure channel passes through the wall of the acid pumping tube and communicates with the inside of the acid pumping tube , a three-way valve 6 for controlling the negative pressure channel is designed on the acid pumping cap, and a balance channel is designed on the side wall of the acid pumping cap, one end of the balance channel communicates with the three-way valve, and the other end of the balance channel communicates with the outside. The bottom surface of the pad is designed with an annular vacuum suction groove 51,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com