Dye-sensitized photoelectric conversion element

A technology for photoelectric conversion elements and photoelectric conversion units, applied in the field of dye-sensitized photoelectric conversion elements, can solve problems such as slow reduction in power generation performance, and achieve the effects of excellent light resistance, excellent photoelectric conversion characteristics and light resistance, and excellent photoelectric conversion characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

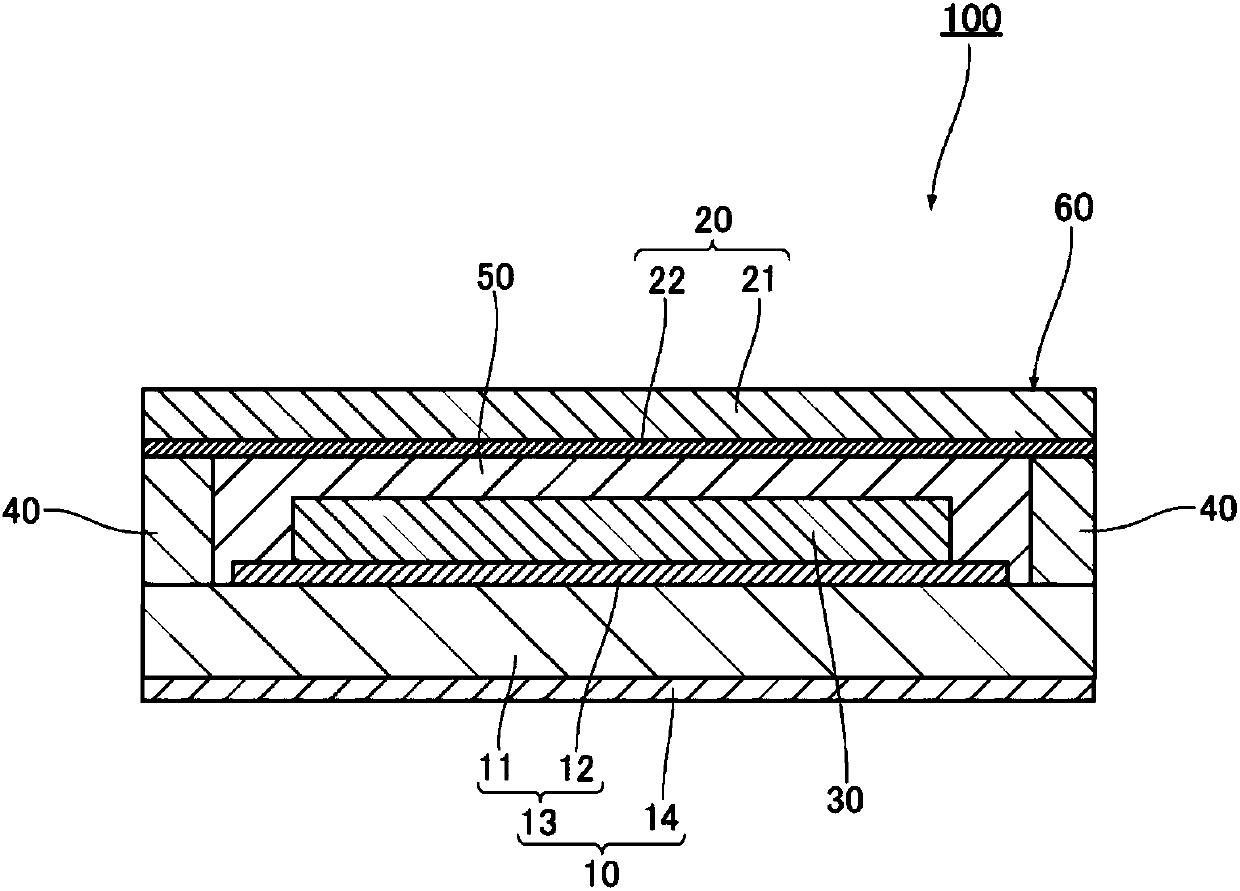

Image

Examples

Embodiment 1

[0117] Hereinafter, although an Example is given and the content of this invention is demonstrated more concretely, this invention is not limited to a following Example.

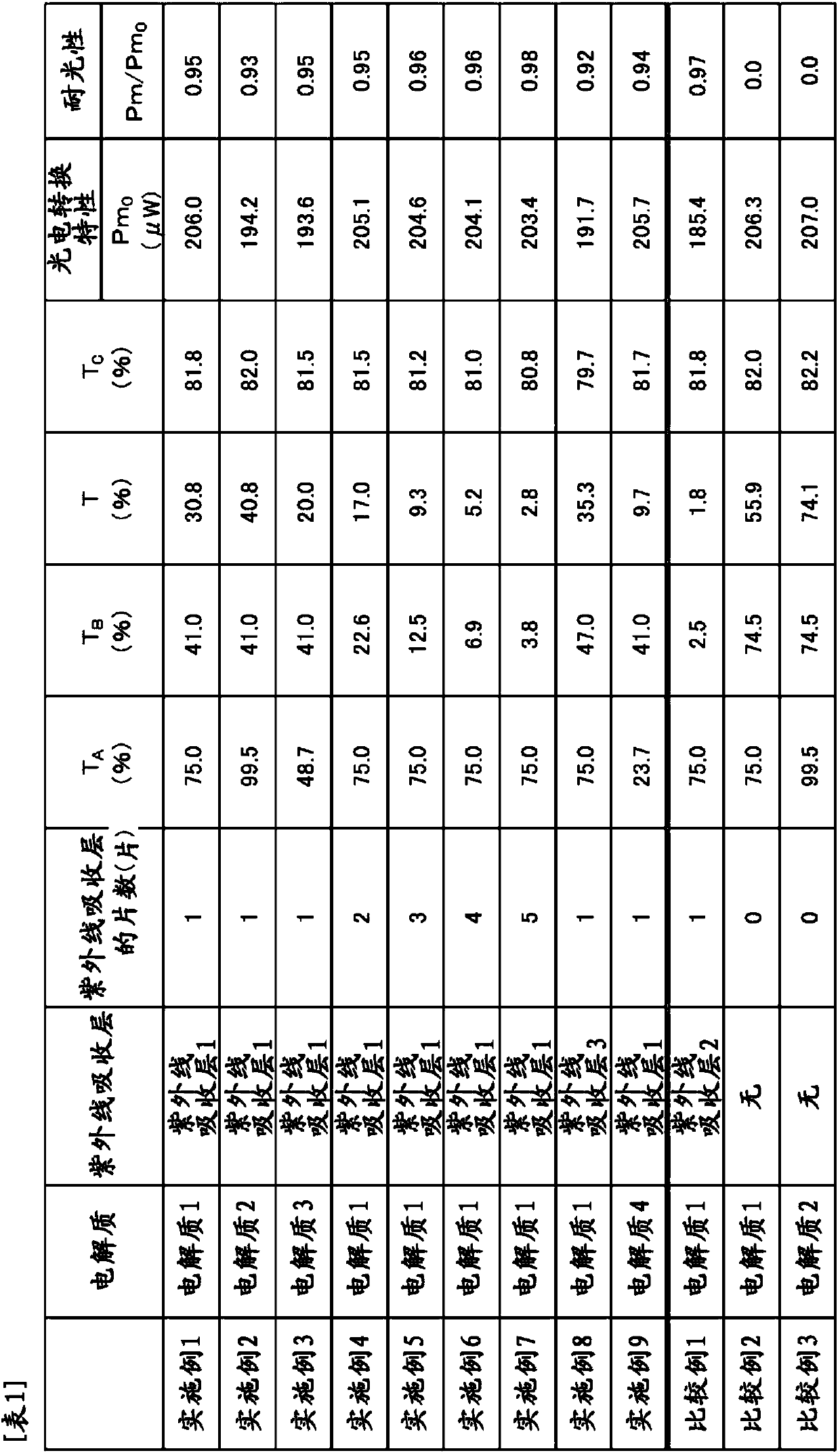

Embodiment 1~9 and comparative example 1~3

[0119]

[0120] (1) Electrolyte

[0121] Electrolytes 1 to 4 having the following compositions were prepared.

[0122] Electrolyte 1

[0123] Iodine (I 2 )0.002M

[0124] 1,2-Dimethyl-3-propylimidazole Iodide (DMPImI) 0.6M

[0125] n-Butylbenzimidazole (NBB) 0.1M

[0126] Solvent composed of 3-methoxypropionitrile (MPN)

[0127] Electrolyte 2

[0128] 1-Hexyl-3-methylimidazolium iodide (HMImI) 0.6M

[0129] n-Methylbenzimidazole (NMB) 0.3M

[0130] Guanidine Thiocyanate (GuSCN) 0.1M

[0131] Solvent composed of 3-methoxypropionitrile (MPN)

[0132] Electrolyte 3

[0133] Iodine (I 2 )0.005M

[0134] 1,2-Dimethyl-3-propylimidazole Iodide (DMPImI) 0.6M

[0135] n-Butylbenzimidazole (NBB) 0.1M

[0136] Solvent composed of 3-methoxypropionitrile (MPN)

[0137] Electrolyte 4

[0138] Iodine (I 2 )0.01M

[0139] 1,2-Dimethyl-3-propylimidazole Iodide (DMPImI) 0.6M

[0140] n-Butylbenzimidazole (NBB) 0.1M

[0141]Solvent composed of 3-methoxypropion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap