Non-contact tool setting gauge

A non-contact, tool setting technology, used in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as production and processing effects, probe wear function, and long working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

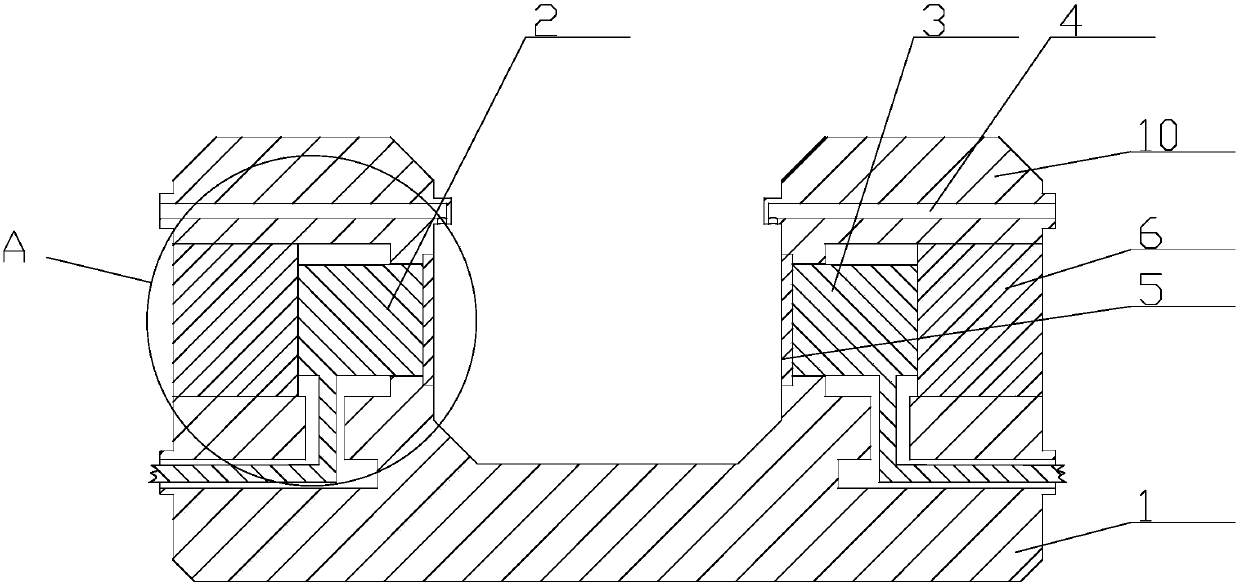

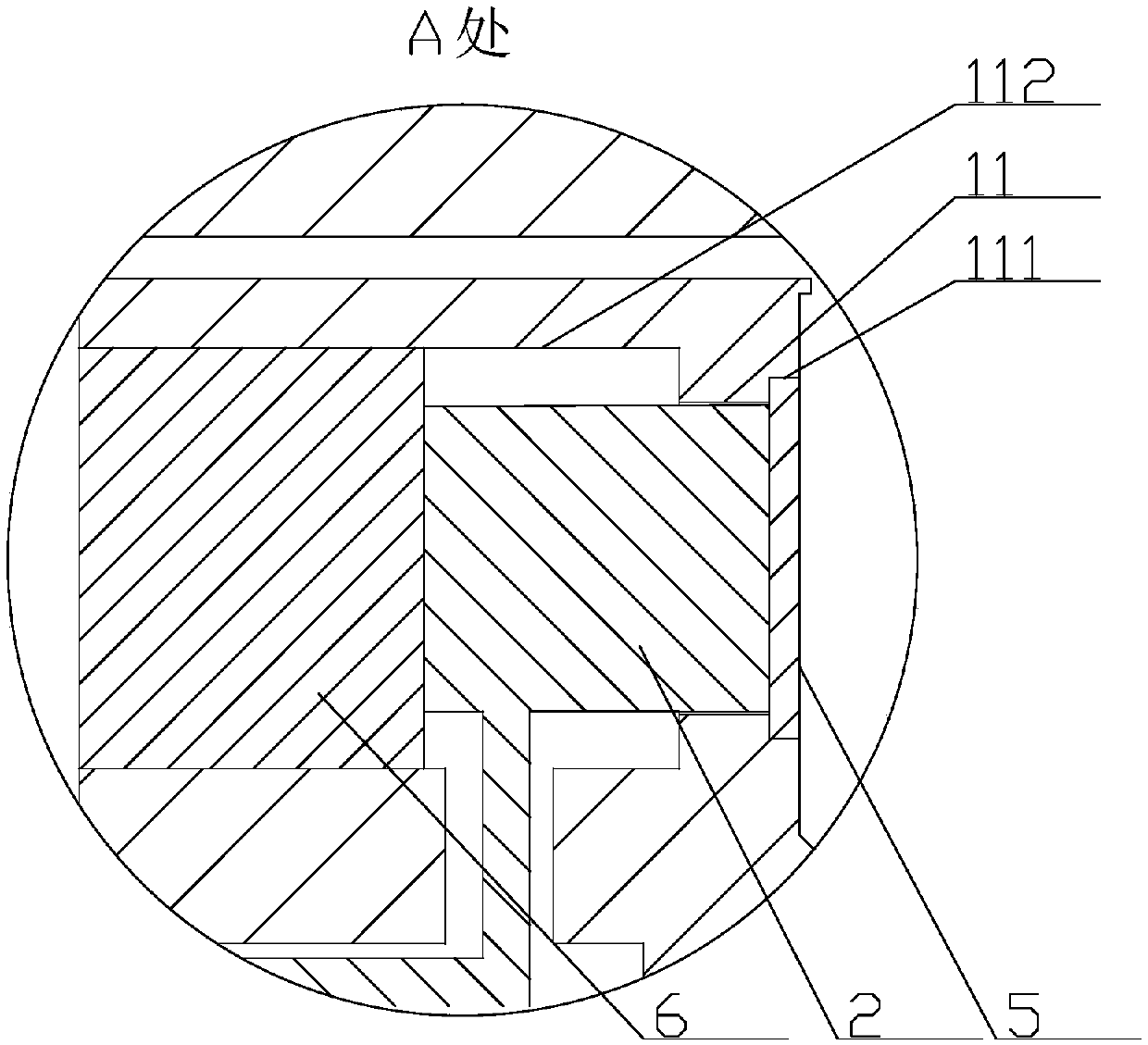

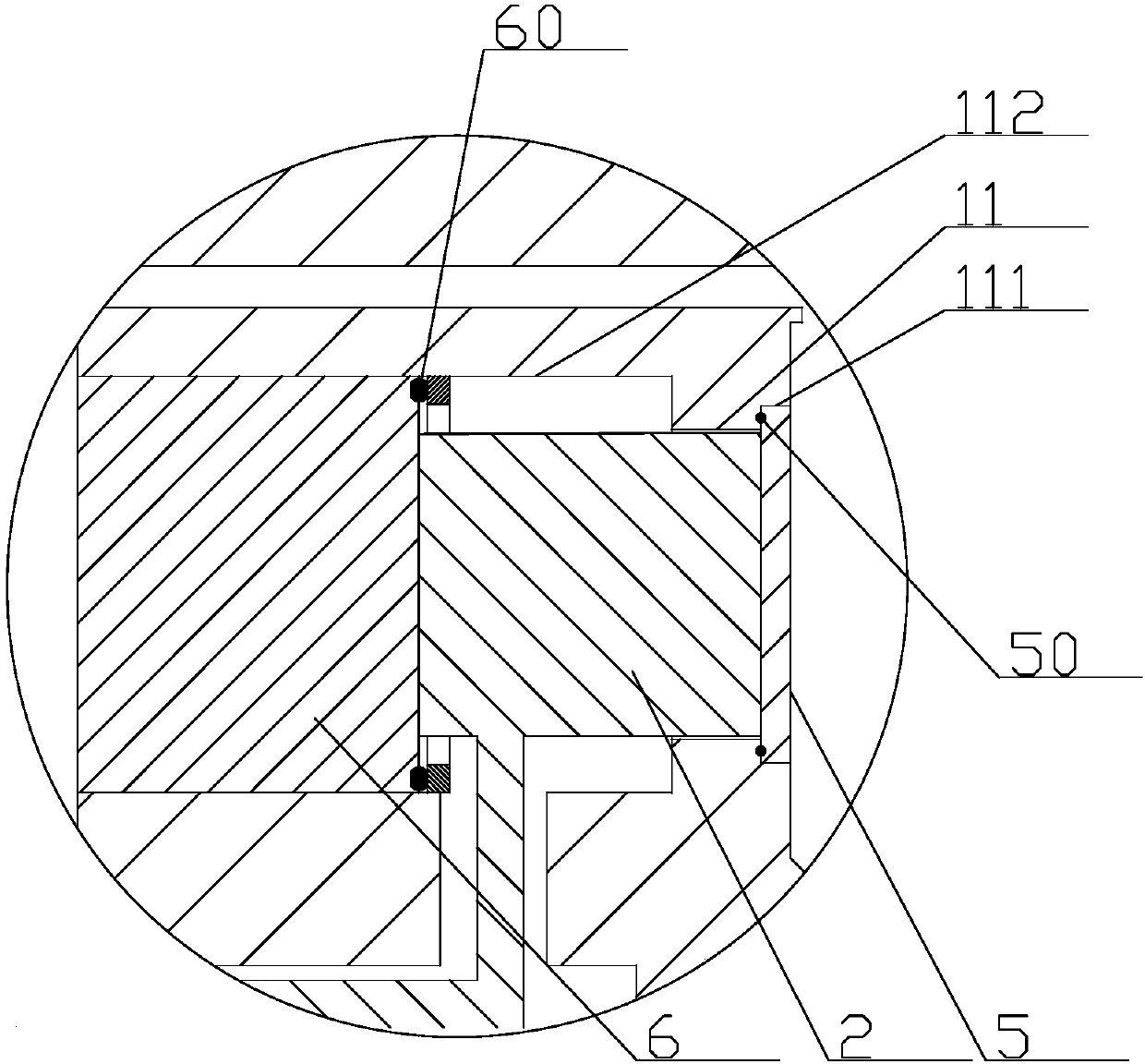

[0022] The present invention as Figure 1-4 As shown, it includes a seat body 1, a laser transmitter 2, a laser receiver 3 and an air blowing assembly 4. The seat body 1 has a pair of mounting seats 10 arranged symmetrically along the center, and the upper part of the mounting seat 10 is provided with Accommodating holes 11, the two accommodating holes 11 are concentric and are respectively used to accommodate the laser transmitter 2 and the laser receiver 3 which are arranged oppositely;

[0023] The tool setting instrument also includes a pair of high-strength lenses 5 and a pair of mounting blocks 6, the high-strength lenses 5 are fixedly connected to the opening of the accommodating hole 11 toward the center of the seat body 1, and the mounting blocks 6 are fixedly connected At the opening of the accommodating hole 11 away from the center of the base body 1, the laser emitter or laser receiver is clamped between the high-strength lens and the mounting block. In this case,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com