Artificial board hot-pressing conveying system

A conveying system and wood-based panel technology, which is applied in the field of bamboo and wood board manufacturing, can solve the problems of increased water content, low processing efficiency, and warped board core of bamboo and wood boards, and achieve the advantages of increasing the contact area, strong applicability, and increasing heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

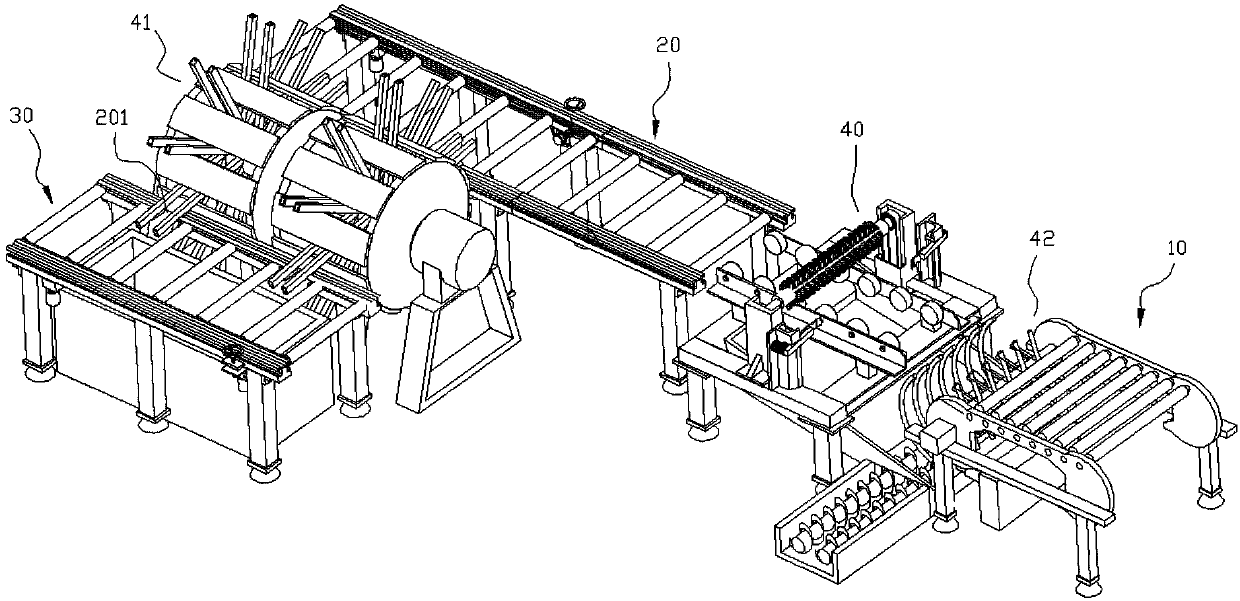

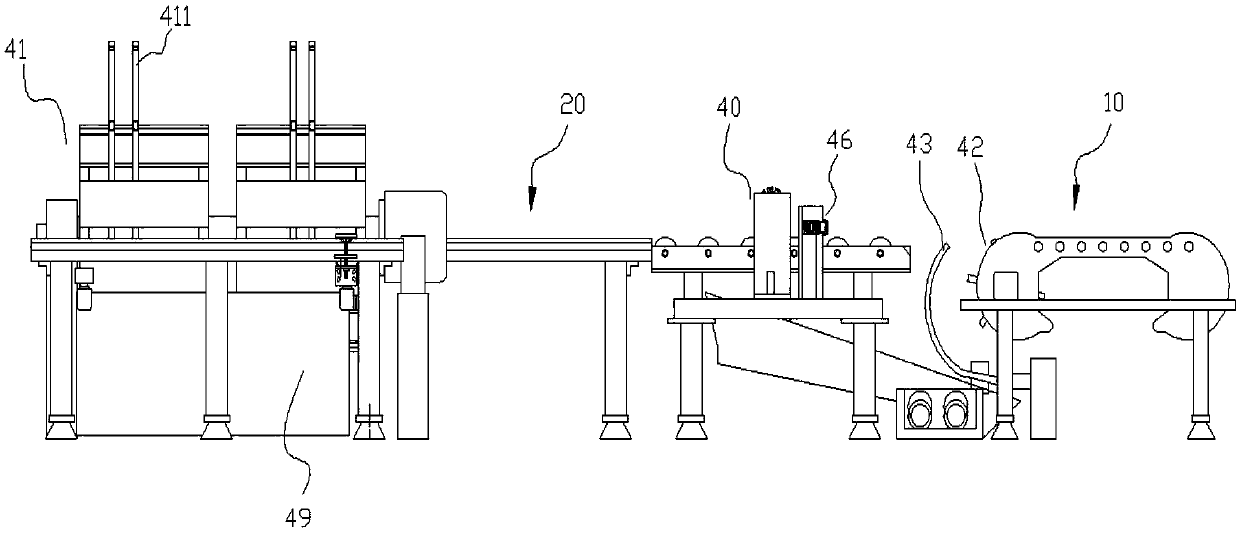

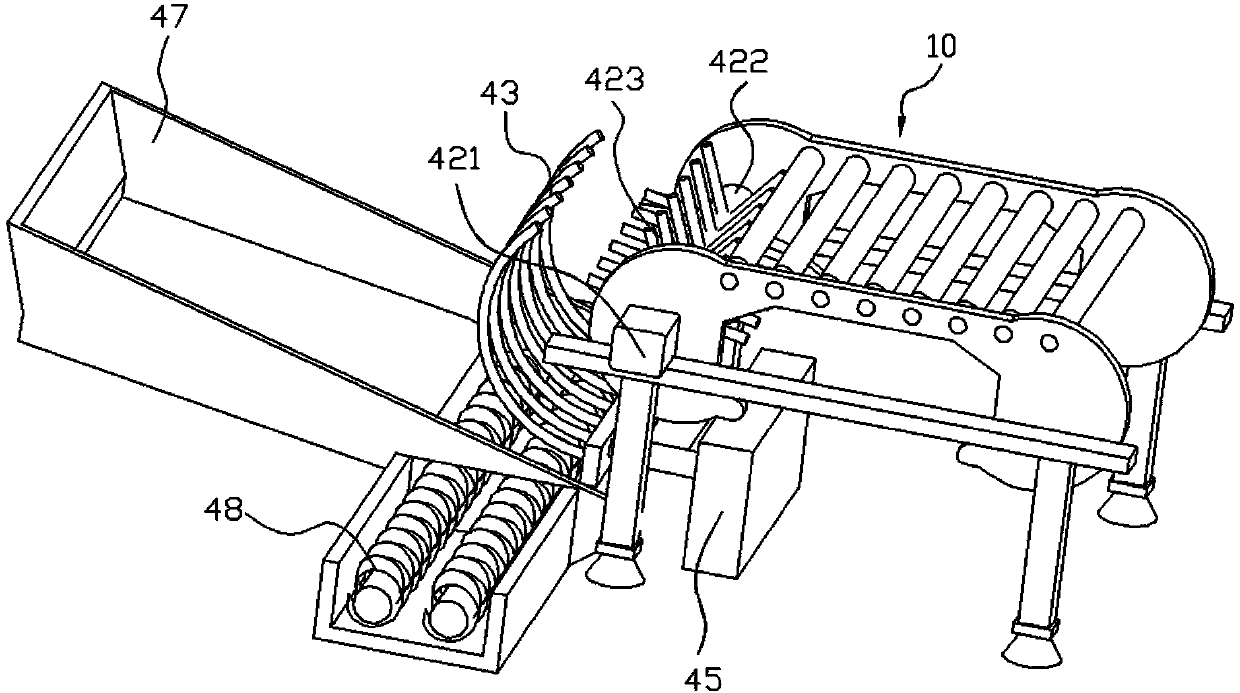

[0026] Such as Figure 1-Figure 7 As shown, the specific structure of the present invention is: a kind of wood-based panel hot-press conveying system, and it comprises conveying frame; It is characterized in that, described conveying frame is made up of three groups of horizontal conveying roller sections; Described first horizontal conveying roller A scraping mechanism 40 is connected between the section 10 and the second horizontal conveying roller section 20, and the second horizontal conveying roller section 20 is connected to the third horizontal conveying roller section 30 through a flap cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com