Hydraulic impact torpedo anchor

A technology of hydraulic impact and hydraulic impactor, which is used in anchor points, ship parts, transportation and packaging, etc., can solve the problems of large mass of torpedo anchors, low installation efficiency, inaccurate orientation, etc., to improve installation efficiency and accuracy. high speed, efficient transportation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

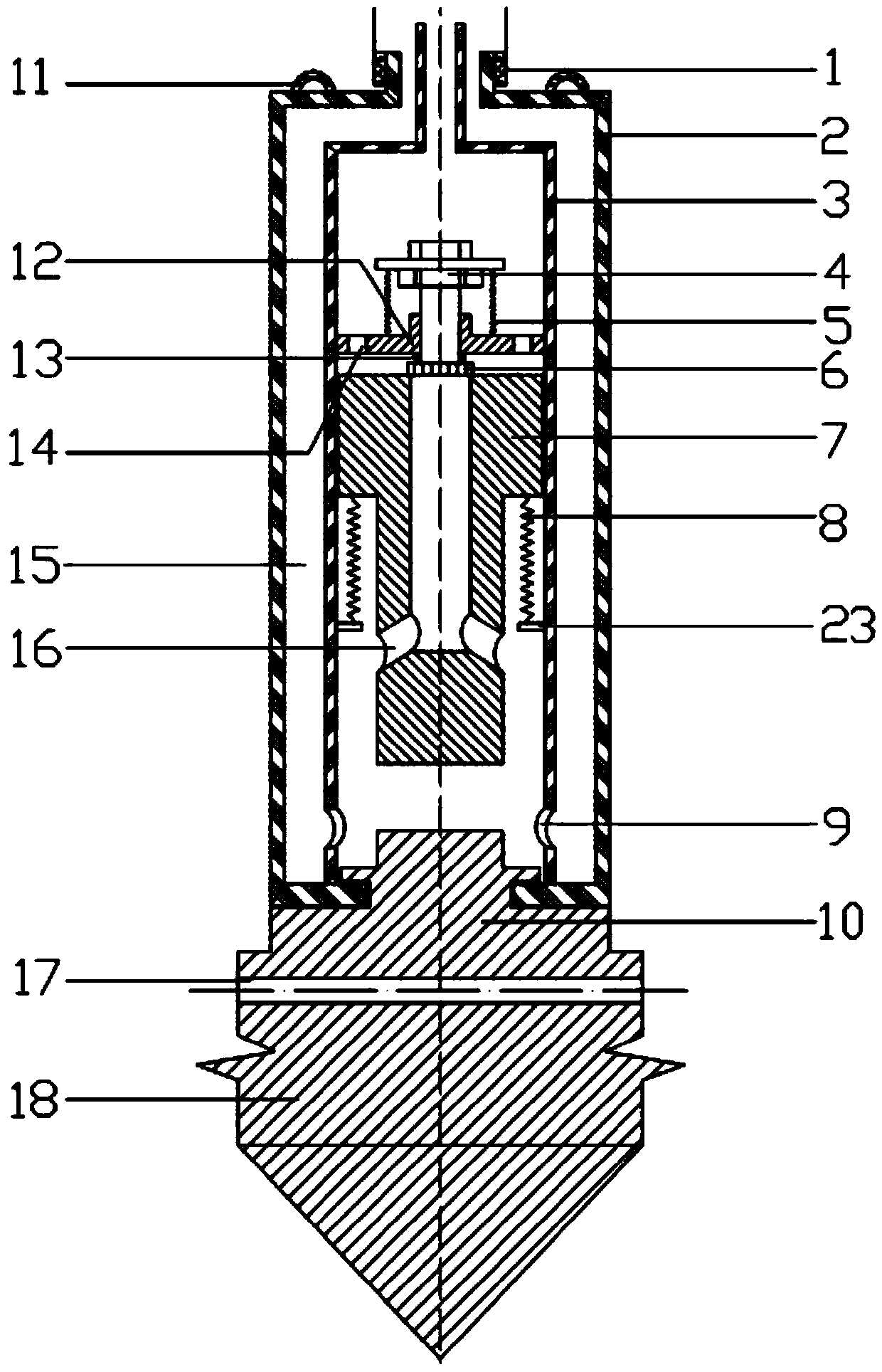

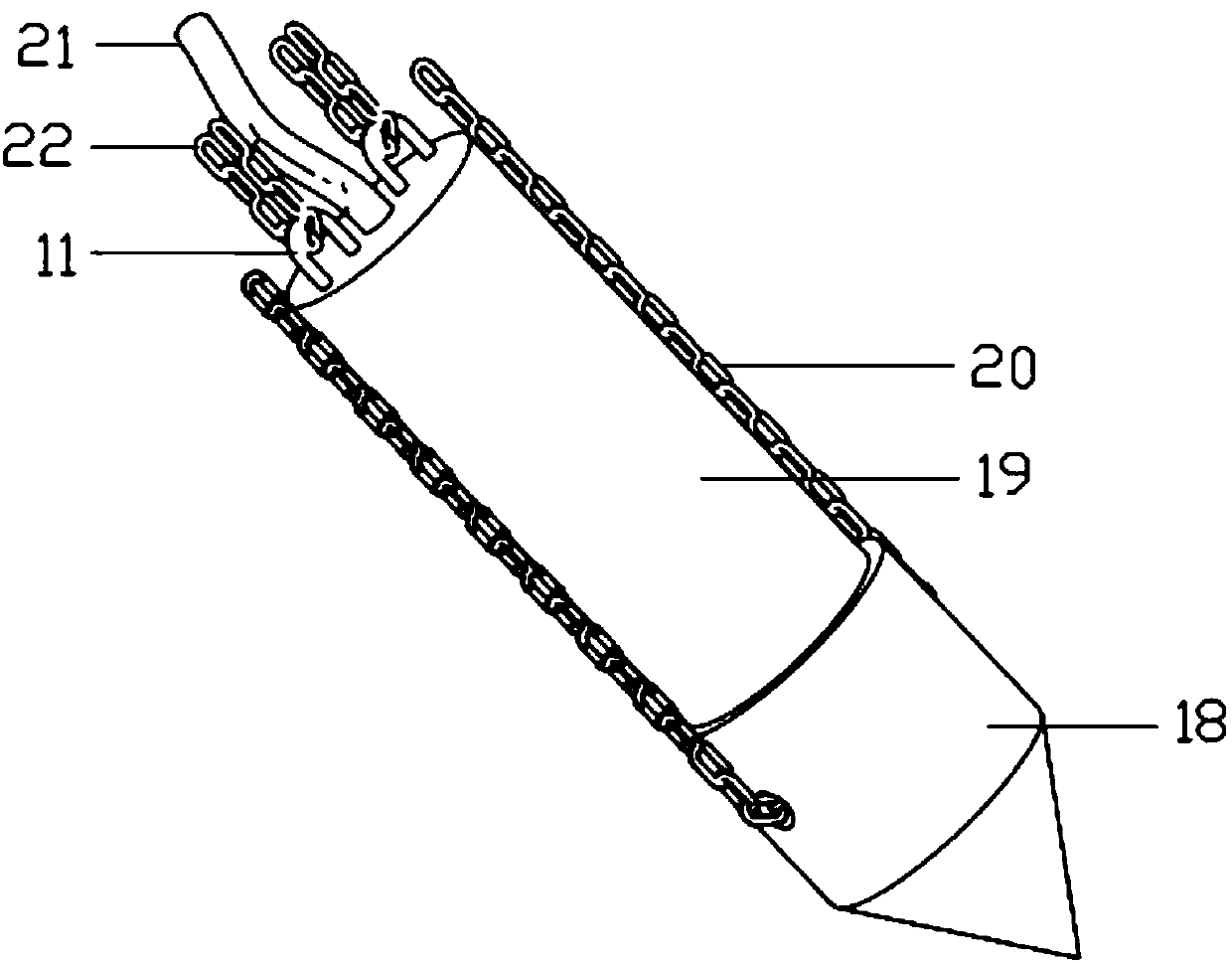

[0024] As shown in the figure, a hydraulic impact torpedo anchor is composed of an anchor head 18, an anchor body 19, an anchor chain, and a hydraulic impactor. The anchor head is set below the anchor body, and the anchor chain is divided into outer anchor chains 20 And the inner anchor chain 22, the outer anchor chain is tied to both sides of the anchor head, and the inner anchor chain is tied to the upper part of the anchor body. The anchor body is cylindrical and divided into an inner shell 3 and an outer shell 2. The upper end of the inner shell structure is open Connected to the water inlet pipe of the hydraulic pipeline 21, the space between the inner shell and the outer shell is called the liquid flow channel 15. The liquid flow channel is connected to the return pipe of the hydraulic pipeline, and a communication hole 9 is provided at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com