Heat pump heat exchange system, heat pump cleaning and drying all-in-one machine or clothes dryer and automatic cleaning method

The technology of a heat exchange system and a clothes dryer is applied in the field of clothes drying, which can solve the problems of low cleaning cost, and achieve the effects of low cleaning cost, prolonged drying time, and increased drying energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

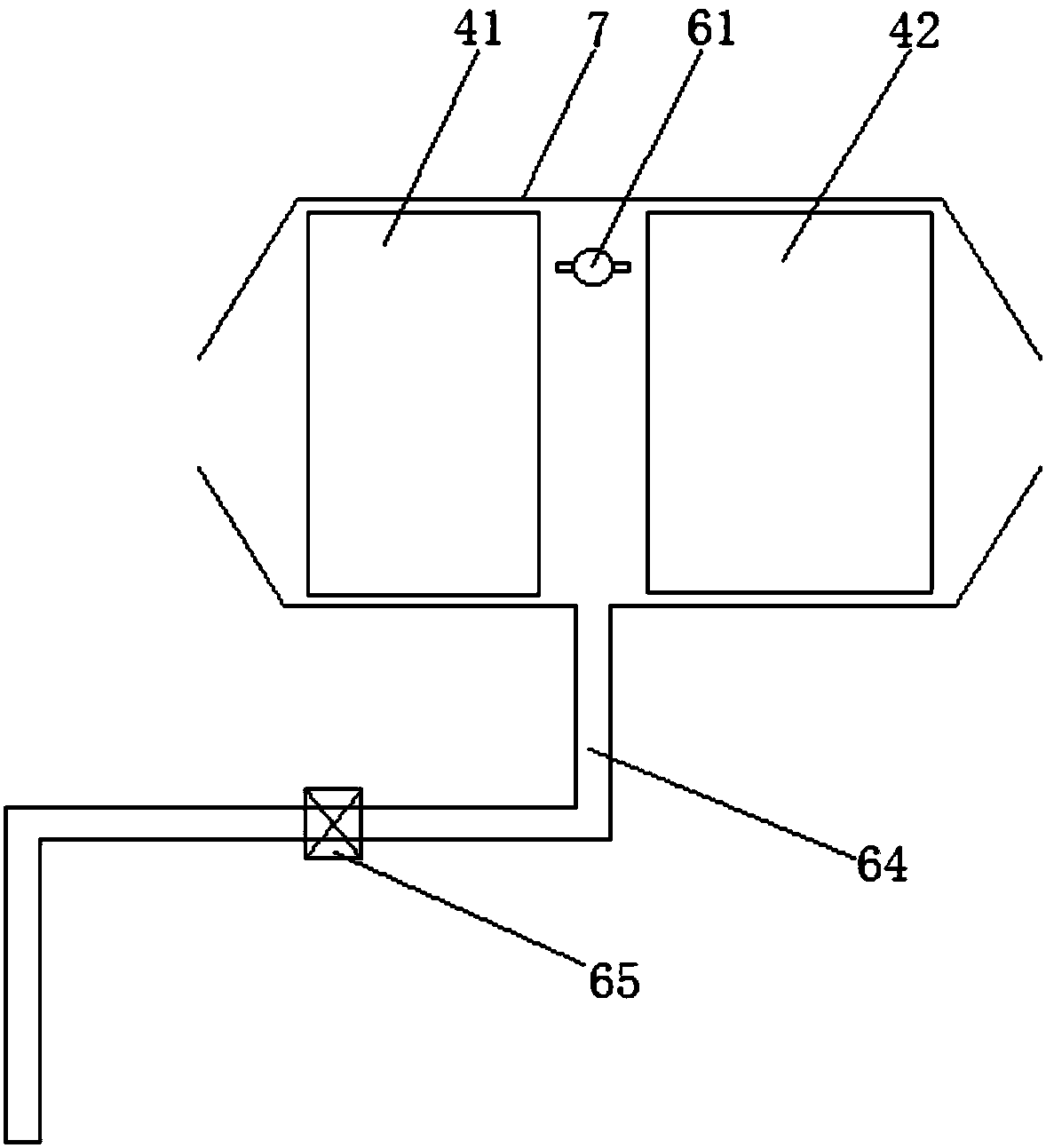

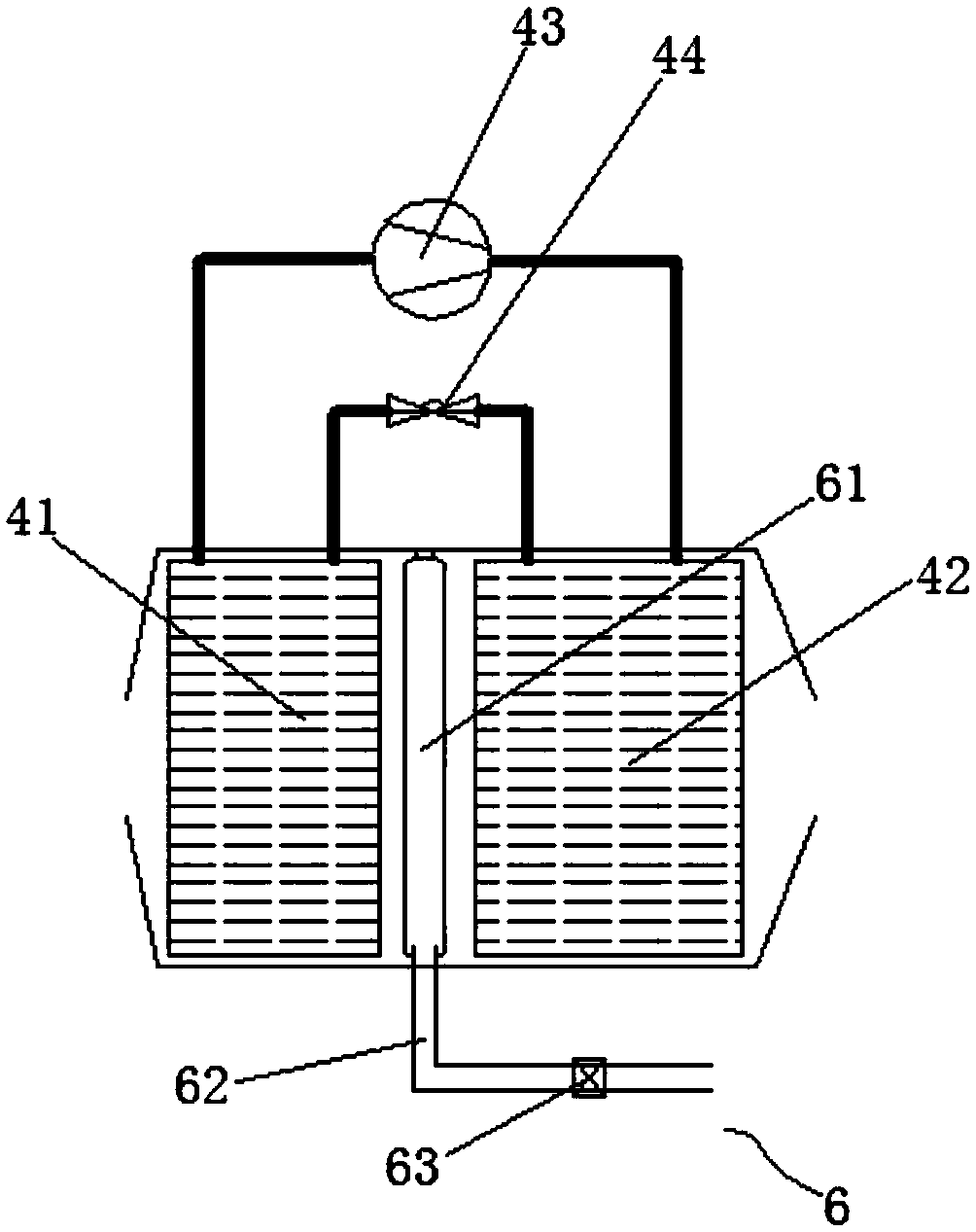

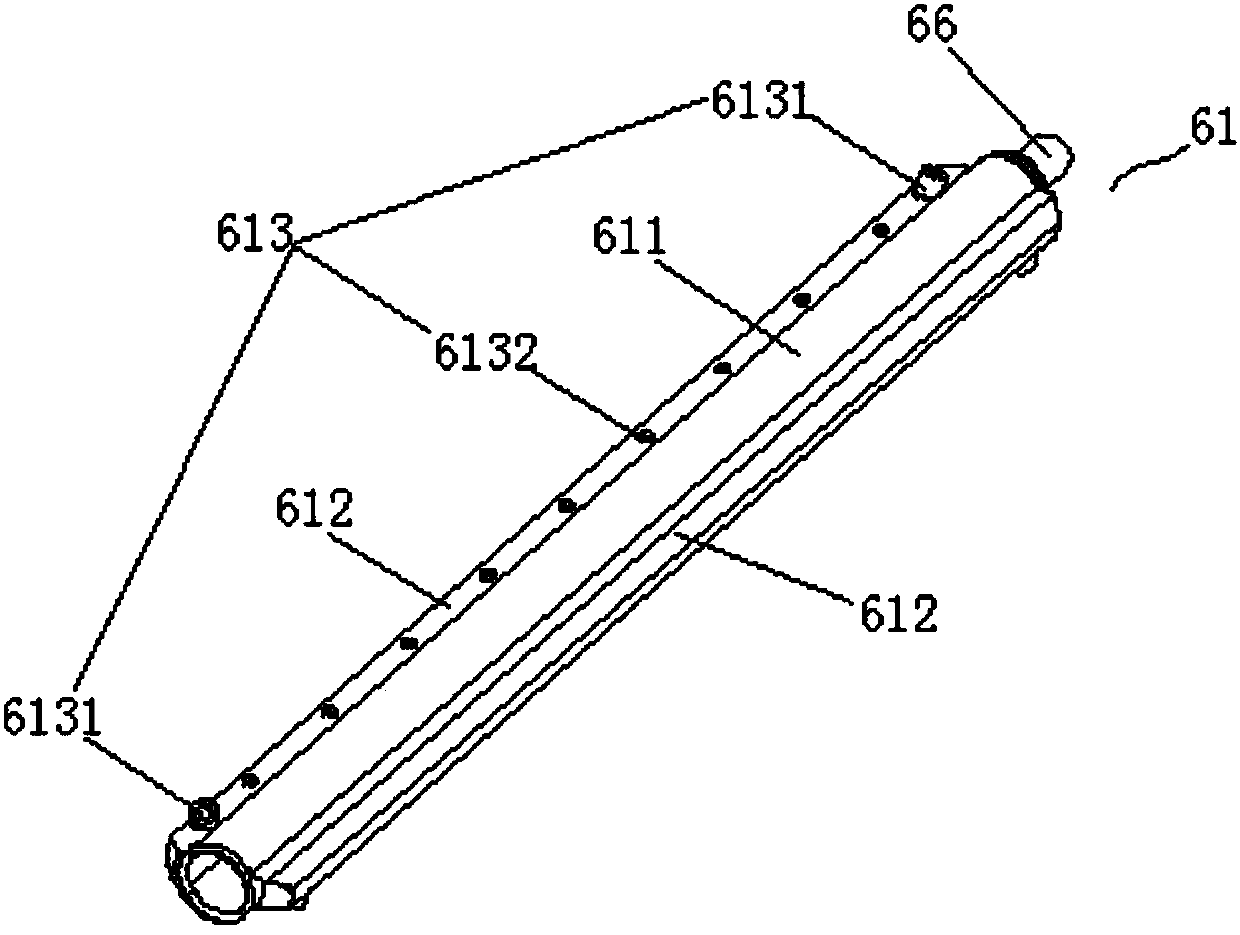

[0033] refer to figure 1 and figure 2 In this embodiment, a heat pump heat exchange system is provided, and the heat pump heat exchange system includes a heat exchange device 4 , a storage box 7 and a flushing device 6 . Wherein, the heat exchange device 4 includes an evaporator 41 and a condenser 42 , and the evaporator 41 and the condenser 42 are housed in the housing box 7 . The flushing device 6 includes an injector, a water inlet mechanism and a drainage mechanism. The injector is located in the holding box 7 and between the evaporator 41 and the condenser 42, so as to be able to spray water to the evaporator 41 and the condenser 42 at the same time; the water inlet mechanism supplies water to the injector; the drainage mechanism communicates with the inside of the holding box 7 , to discharge the water in the holding box 7.

[0034] In the heat pump heat exchange system of this embodiment, the heat exchanger (the evaporator 41 and the condenser 42) is integrated in t...

Embodiment 2

[0045] refer to Figure 4 and Figure 5 , In this embodiment, there is provided a heat pump washing and drying machine or a heat pump clothes dryer, which includes the heat pump heat exchange system described in the first embodiment above.

[0046] The heat pump washing and drying machine or the heat pump dryer can be fully cleaned because the heat exchanger can be fully cleaned without reducing the heat exchange efficiency, prolonging the drying time, and increasing the drying energy consumption due to the accumulation of fluff on the surface of the heat exchanger. High problem, and the cleaning cost is low.

[0047] Further, in this embodiment, the heat pump washing and drying machine or the heat pump dryer also includes a drying chamber 1 and an air duct 2, and the drying chamber 1 can be a drum of a washing machine or a clothes dryer, or can be a cabinet type clothes dryer A drying room for the clothes to be dried. The air channel 2 is connected and fluidly communicated...

Embodiment 3

[0050] refer to Figure 6 , in this embodiment, an automatic cleaning method based on the heat exchange device 4 of the heat pump washer-dryer or the heat pump dryer described in Embodiment 2 is provided, and the following steps are automatically performed after the drying step is completed:

[0051] S1. Water is fed into the injector through the water inlet mechanism, and the injector sprays water to the evaporator 41 and the condenser 42 at the same time, and drains water through the drainage mechanism;

[0052] S2, stop water inflowing into the injector and discharge water from the injector;

[0053] S3, blowing air to the evaporator 41 and the condenser 42.

[0054] Through the automatic cleaning method, the heat exchanger can be cleaned in time to prevent the accumulation of clothing fluff on the surface of the heat exchanger, so that the heat pump washing and drying machine or the heat pump dryer adopting the automatic cleaning method will not have the accumulation of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com