Pipe rack automatic spraying cart curing device and spraying method thereof

A technology of trolley and pipe gallery, which is applied in the field of automatic sprinkler maintenance devices for underground pipe gallery, can solve problems such as leakage maintenance, and achieve the effects of wide applicability, simple structure, and convenient installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

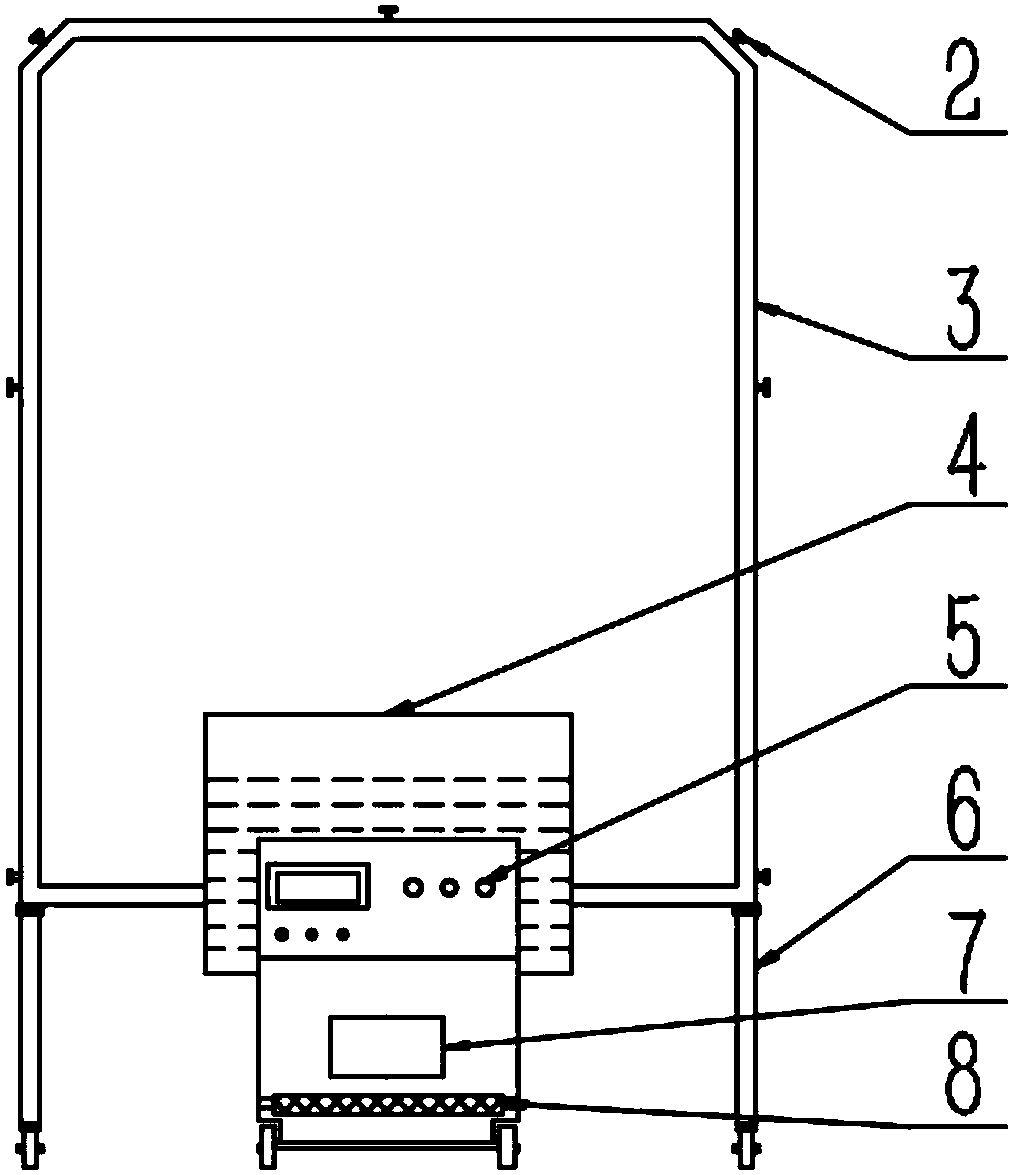

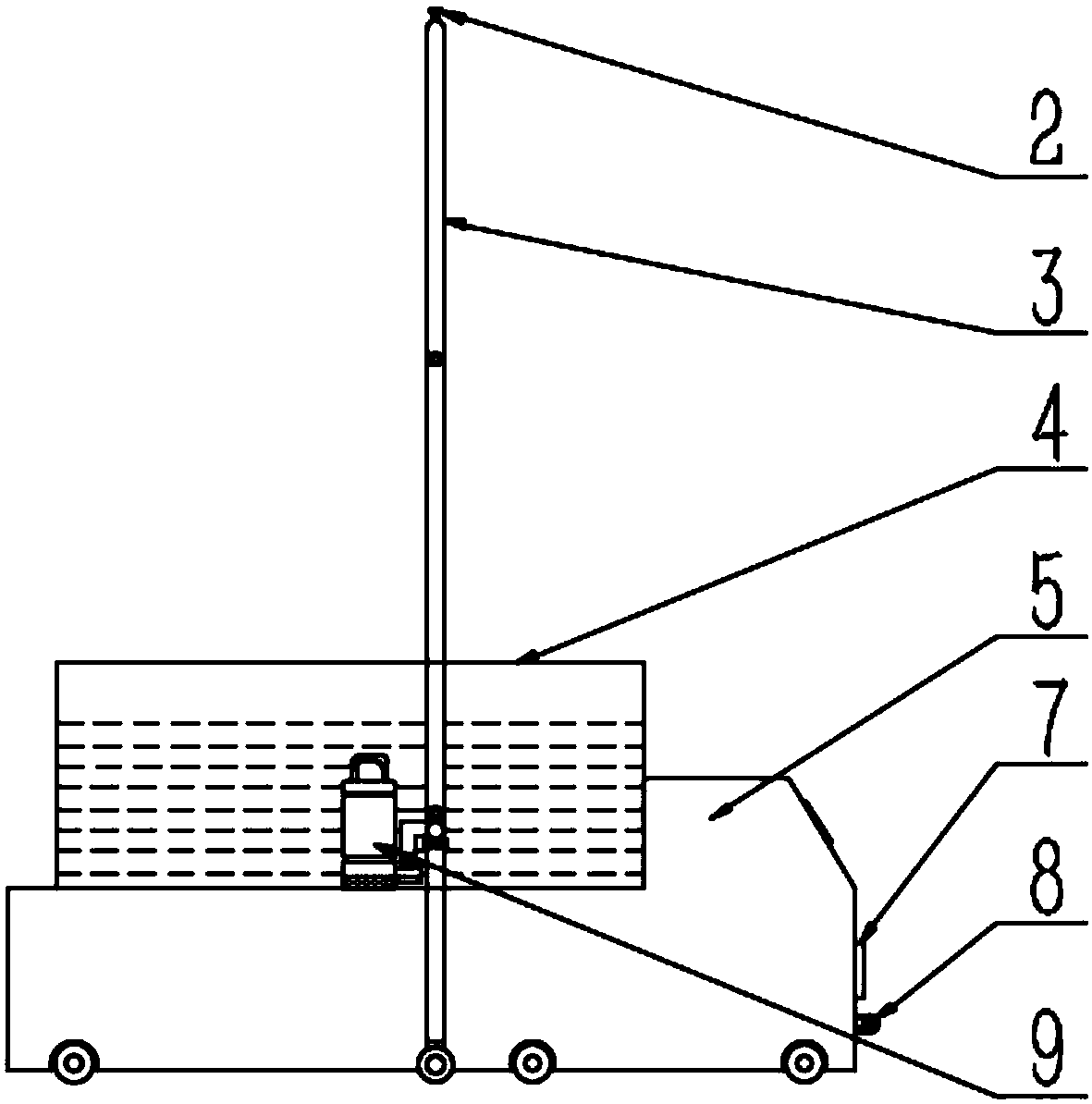

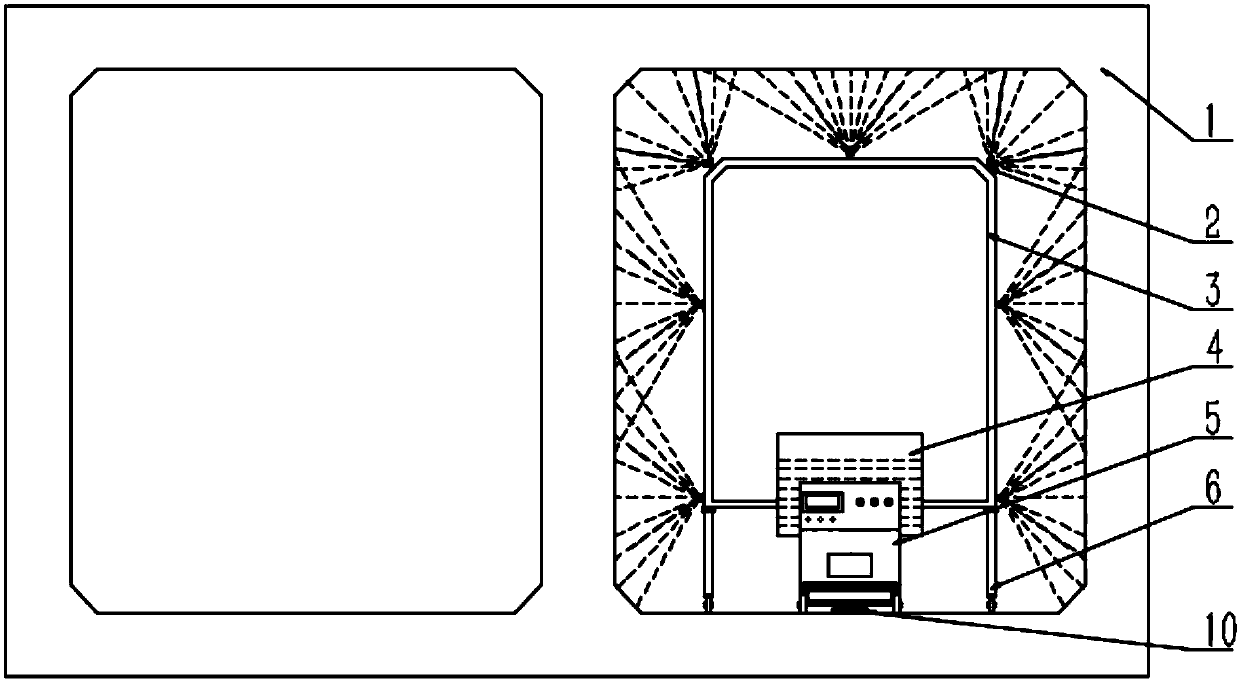

[0026] Such as figure 2 Shown is the maintenance device for the automatic spray trolley of the pipe gallery described in this example, and the present invention will be further described below in conjunction with the accompanying drawings. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0027] A maintenance device for fully automatic spray trolleys for pipe galleries, characterized in that it includes a transport trolley 5. In the embodiment, an automatic guiding trolley, a water tank 4, a spray pump 9, a spray pipeline 3, a spray pipeline support 6, a guide Magnetic strip 10, the transport trolley 5 is provided with a guide assembly: a guide magnetic strip 10 is pre-laid on the preset spray path of the trolley, and the bottom wheel of the transport trolley 5 is matched with the guide magnetic strip 10 ;

[0028] The transport trolley 5 is provided with a spray assembly: the transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com