Tunnel invert repair secondary lining reinforcing structure and construction method

A technology of secondary lining and construction method, which is applied in the direction of earthwork drilling, directional drilling, mining equipment, etc., and can solve the problems of inability to form a whole structure, unclean concrete surface of inverted arch and inverted arch backfill, and difficulty in ensuring the durability of the repaired structure, etc. problems, to achieve the effect of ensuring safety and improving construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

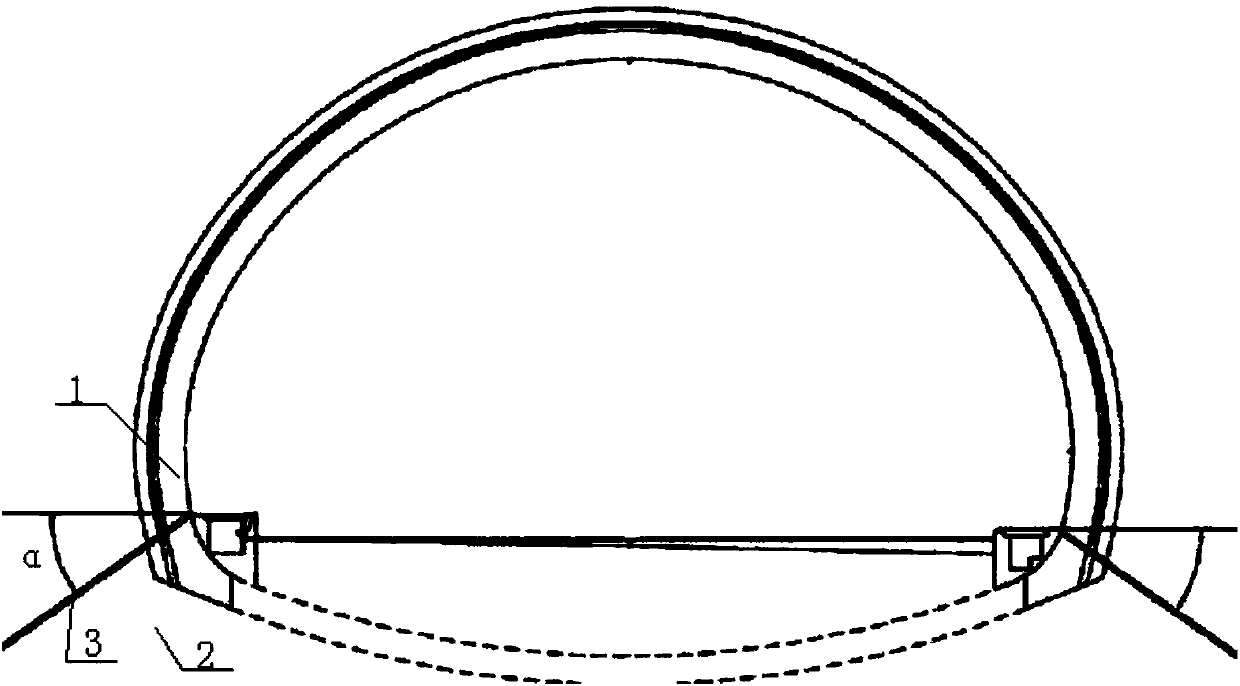

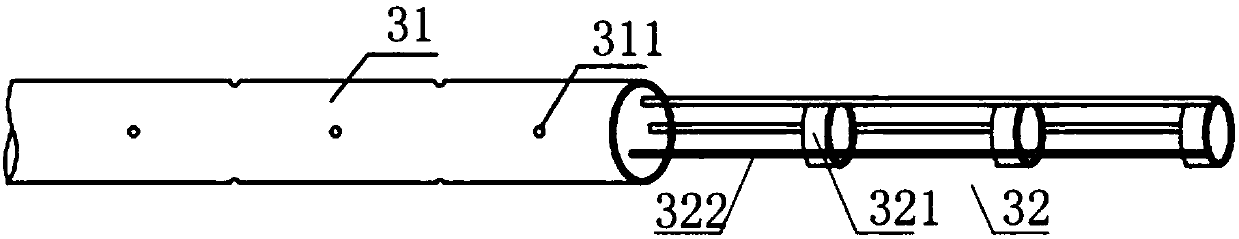

[0029] combine figure 1 and figure 2 As shown, the secondary lining reinforcement structure for repairing the inverted arch of the tunnel according to the present invention includes reinforcement holes opened at the foot of the side wall of the secondary lining 1 of the tunnel and inclined outward and downward. The reinforcement holes pass through the secondary lining 1 and extend to the surrounding rock 2 Inside, the reinforcement hole is not drawn in the figure, the steel pipe anchor pile 3 is installed in the reinforcement hole, the steel pipe anchor pile 3 in the reinforcement hole is drawn in the figure, the steel pipe anchor pile 3, the steel pipe anchor pile 3 and the The gaps between the reinforcement holes are all filled with cement mortar; the steel pipe anchor pile 3 includes a lock foot anchor pipe 31, a steel tendon 32 inserted into the lock foot anchor pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com