A method for detecting foaming force of heat-sensitive adhesive tape

A detection method and technology of foaming force, applied in the field of lithium ion batteries, can solve the problems such as performance degradation of aluminum foil or copper foil, reduction of unit capacity after the service life of lithium ion battery, and detection methods failing to meet requirements, so as to improve unit capacity, The effect of improving the service life and reducing the economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

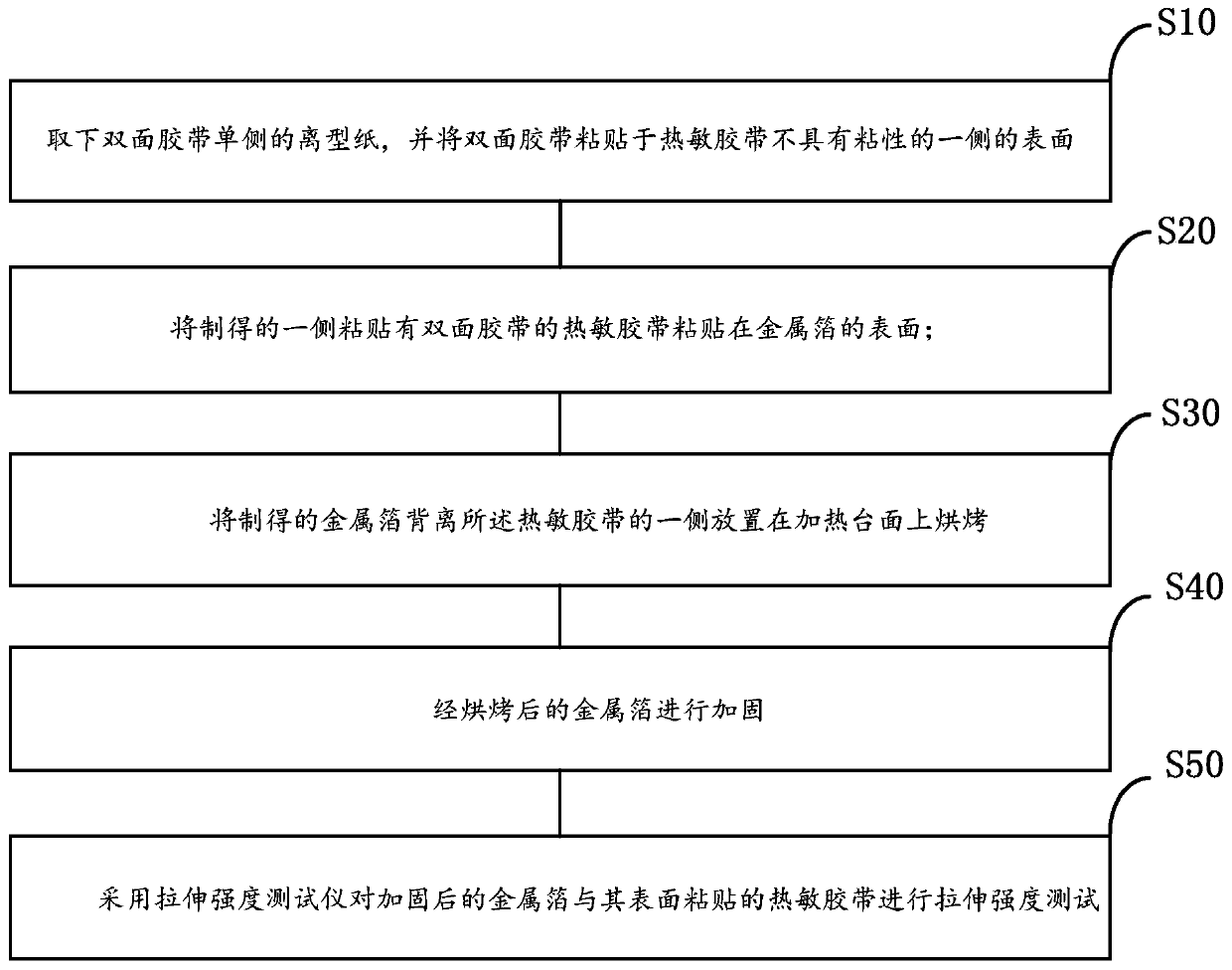

[0067] Remove the release paper on one side of the double-sided tape, and stick the double-sided tape on the surface of the non-adhesive side of the thermal tape; then paste the prepared thermal tape with the double-sided tape on the aluminum foil The surface of the aluminum foil has a thickness of 8 μm; then place the side of the prepared aluminum foil away from the heat-sensitive adhesive tape on a heating table for baking, the baking temperature is 70 degrees, and the baking time is 20 seconds; the baked The side of the aluminum foil facing away from the heat-sensitive tape is pasted with ordinary tape to strengthen the strength of the aluminum foil; a tensile strength tester is used to test the tensile strength of the reinforced aluminum foil and the heat-sensitive tape pasted on its surface; the test speed is 3mm / min; fix the aluminum foil and the heat-sensitive tape with double-sided tape on both ends of the tensile strength tester, and the tensile strength tester separa...

Embodiment 2

[0069] Remove the release paper on one side of the double-sided tape, and stick the double-sided tape on the surface of the non-adhesive side of the thermal tape; then paste the prepared thermal tape with the double-sided tape on the copper The surface of the foil, the thickness of the copper foil is 12 μm; then place the side of the prepared copper foil away from the thermal tape on the heating table for baking, the baking temperature is divided into two stages, the heating temperature of the first stage is 80 degrees, the baking time is 20 seconds; the second stage heating temperature is 101 degrees, the baking time is 20 seconds; after baking, use a rubber roller with a mass of 2000g to paste one side at a rolling speed of 300mnm / min The process of pressing the heat-sensitive tape with double-sided tape on the surface of the copper foil to avoid air bubbles at the joint between the heat-sensitive tape and the copper foil; after that, stick the ordinary tape on the side of th...

Embodiment 3

[0071] Place the thermal tape in an environment with a temperature of 23°C±2°C and a relative humidity of 55%±5% for two hours, remove the release paper on one side of the double-sided tape, and paste the double-sided tape On the surface of the non-adhesive side of the heat-sensitive tape; then stick the heat-sensitive tape with the double-sided tape on the surface of the copper foil, and the thickness of the copper foil is 15 μm; Place the side away from the thermal tape on the heating table for baking. The baking temperature is divided into two stages. The heating temperature of the first stage is 100 degrees, and the baking time is 21 seconds; the heating temperature of the second stage is 102 degrees. , the baking time is 21 seconds; after baking, use a rubber roller with a mass of 2000g to press the heat-sensitive tape with double-sided tape on the surface of the copper foil at a rolling speed of 300mnm / min. Avoid the presence of air bubbles at the joint between the heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com