A Grease Dropping Point Tester That Can Measure Continuously

A measuring instrument and grease technology, which is applied in the field of grease measuring equipment, to achieve the effect of increasing effective working time and improving the efficiency of repeated measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

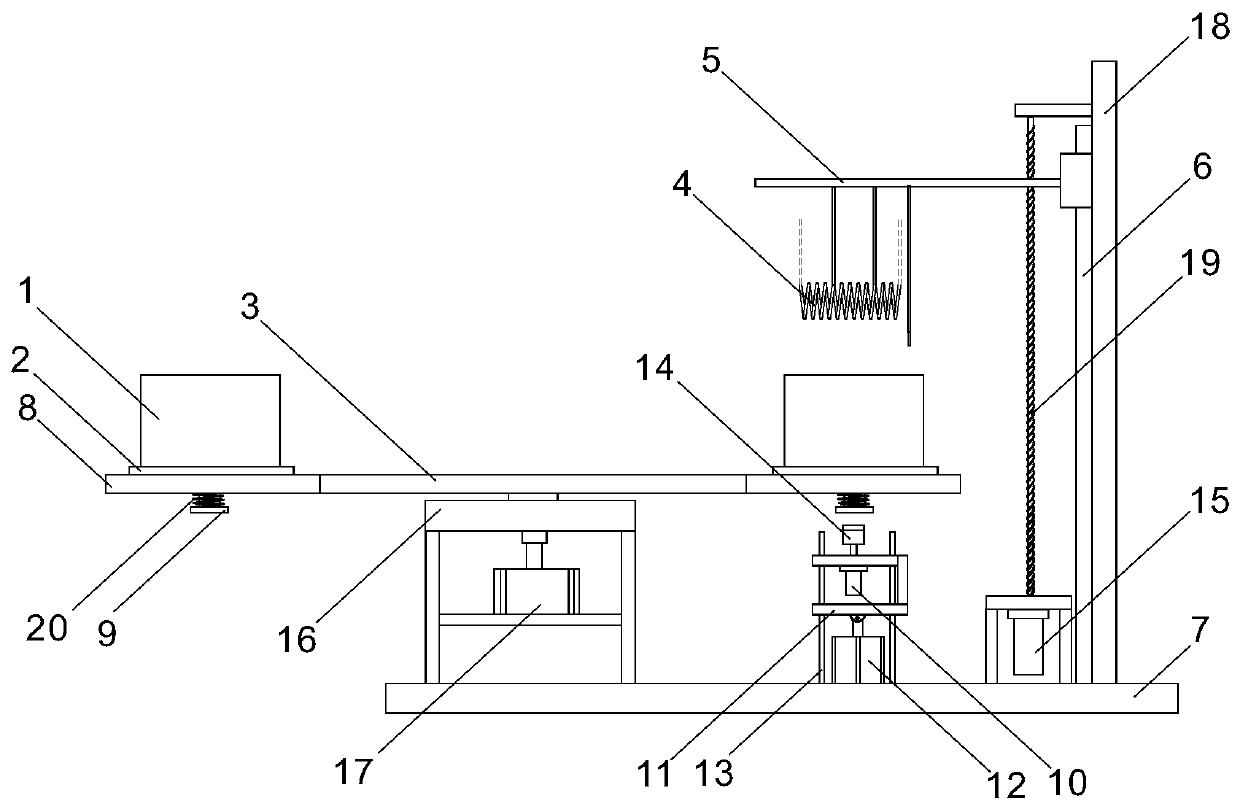

[0019] Such as figure 1 As shown, a grease drop point tester that can be tested continuously includes a measuring device and a cuboid oil bath box 1, and also includes an oil bath rapid temperature return device. The oil bath rapid temperature return device includes a refrigerator, a temperature return mold Group, oil bath box tray 2 and the swing arm 3 that can divide and rotate, the swing arm 3 is inline and the middle part is provided with a rotating shaft, and the rotating shaft runs through and rotates and is connected on a swing arm support platform 16, and a swing arm support platform 16 is provided below with a Swing cylinder 17, the swing angle of swing cylinder 17 is 180 °. There are two oil bath trays 2 and they are fixed on the two free ends of the swing arm 3. The oil bath 1 is placed on the oil bath tray 2, and the rotation path of the swing arm 3 has a measurement positioning point and a temperature recovery positioning point. The position of the device corresp...

Embodiment 2

[0022] The swing arm 3 is Y-shaped with a rotating shaft in the center, and there are three oil bath trays 2 fixed on the three free ends of the swing arm 3 . The angle between the three oil bath trays 2 relative to the central rotating shaft of the swing arm 3 is 120°. The swing arm 3 is driven to rotate by a stepping motor. The oil bath box 1 is cylindrical, and the oil bath box tray 2 is fixed with three oil bath box limit elastic pressure blocks, and the oil bath box space limit elastic pressure blocks are evenly distributed on a circular arc path. There are four guide rods 13. All the other are with embodiment 1.

[0023] In the present embodiment, there is one more standby oil bath tank positioning point on the rotation path of the swing arm 3, and the oil bath that has been cooled is first transferred to the standby oil bath tank positioning point with the rotation of the swing arm 3 for 120°, and the measured The oil bath is still transferred directly from the assay...

Embodiment 3

[0025] The swing arm 3 is cross-shaped and the center is provided with a rotating shaft. There are four oil bath trays 2 fixed on the four free ends of the swing arm 3. There are four oil bath tanks 1 for turnover. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com