Vibration reduction control method and control device for power source, p2 hybrid module

A control method and a technology of a control device, which are applied in the field of vehicles, can solve the problems of limited layout of engines and drive motors, limited layout space, and increased volume of dual-mass flywheels, and achieve optimal layout, volume reduction, and vibration reduction requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

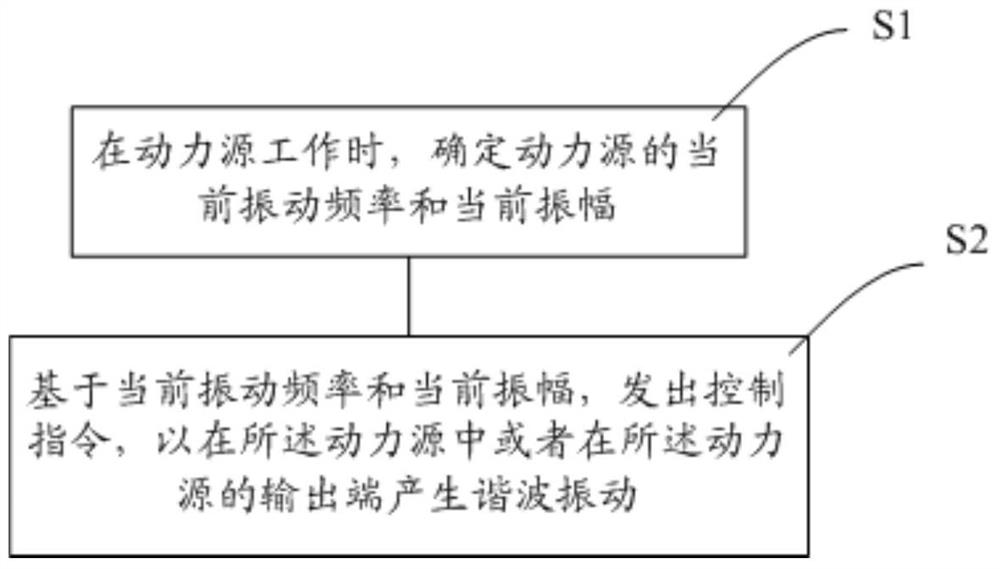

[0039] The embodiment of the present invention provides a power source damping control method, the power source is an engine or drive motor, reference figure 1 As shown, the damping control method includes:

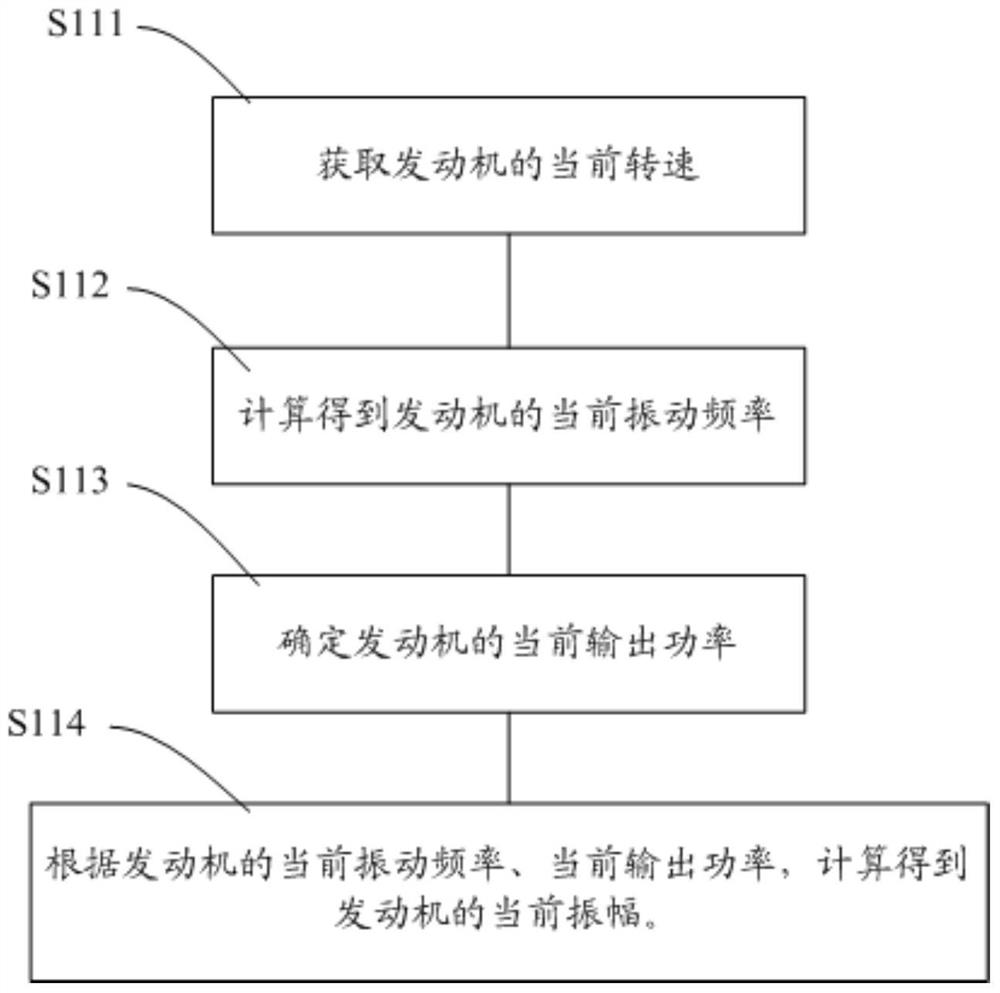

[0040] Step S1: When the power source is working, the current vibration frequency and the current amplitude of the power source are determined;

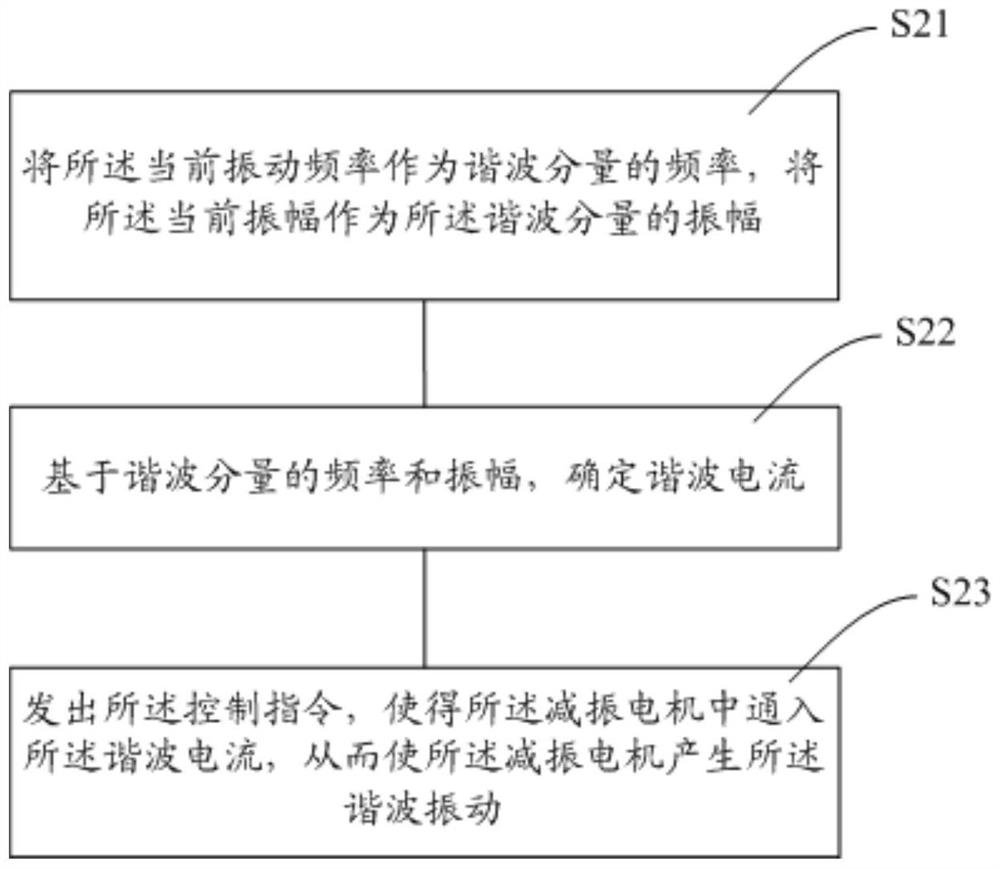

[0041] Step S2: Based on the current vibration frequency and the current amplitude, the control command is issued to generate harmonic vibration in the power source or at the output of the power source, the vibration frequency of the harmonic vibration is the same as the current vibration frequency, harmonics The vibration direction of the vibration is opposite to the current vibration direction.

[0042] In gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com