Protective sheath for at least one electrical conductor

A technology of protective sleeve and electrical conductor, applied in the field of protective sleeve, can solve the problem of not being able to withstand high temperature without damage, and achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

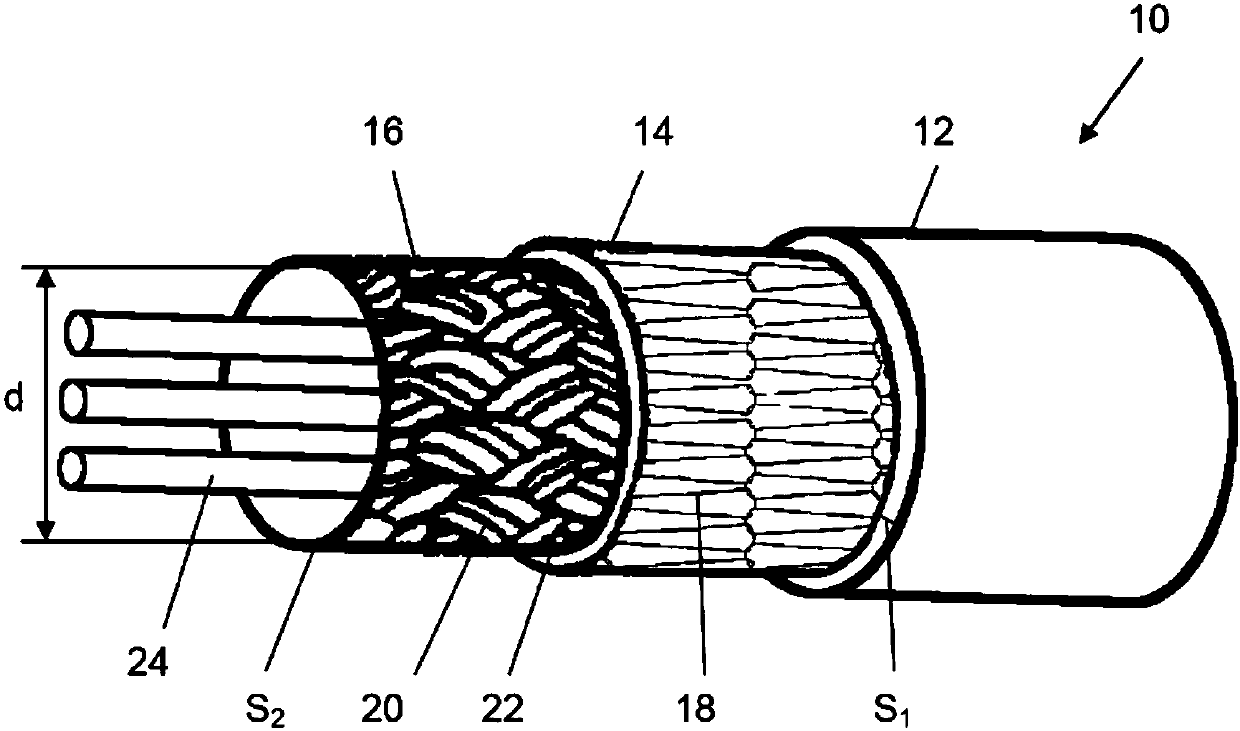

[0028] exist figure 1 In general, 10 denotes a protective sheath according to the invention, which in this embodiment has a substantially cylindrical shape. A protective case 10 according to the present invention includes an outer layer 12 , an intermediate layer 14 and an inner layer 16 .

[0029] The outer layer 12 is made of thermoplastic elastomer (TPE), wherein the outer layer 12 is applied on the middle layer 14 by using an extrusion process.

[0030] exist figure 1 In the embodiment shown in, the outer layer 12 is designed to be seamless and non-porous, wherein the wall thickness S of the outer layer 12 1 Here it is approximately 0.6 mm.

[0031] The middle layer 14 is designed as a knitted hose. The knitted fabric is here formed from one or more threads 18 . exist figure 1 In the embodiment shown in , the knitted fabric of the middle layer 14 is formed of pure aramid. The length-specific weight of the intermediate layer 14 is here approximately 1610 dtex.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com