Tail-gas recycling system as well as tail-gas recovery type culture farm

A tail gas recovery and tail gas technology, applied in the application, poultry industry, climate change adaptation and other directions, can solve the problems of unenvironmental protection, tail gas heat recovery and utilization, environmental pollution, etc., to achieve environmental protection, high utilization efficiency, and promotion of plant growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

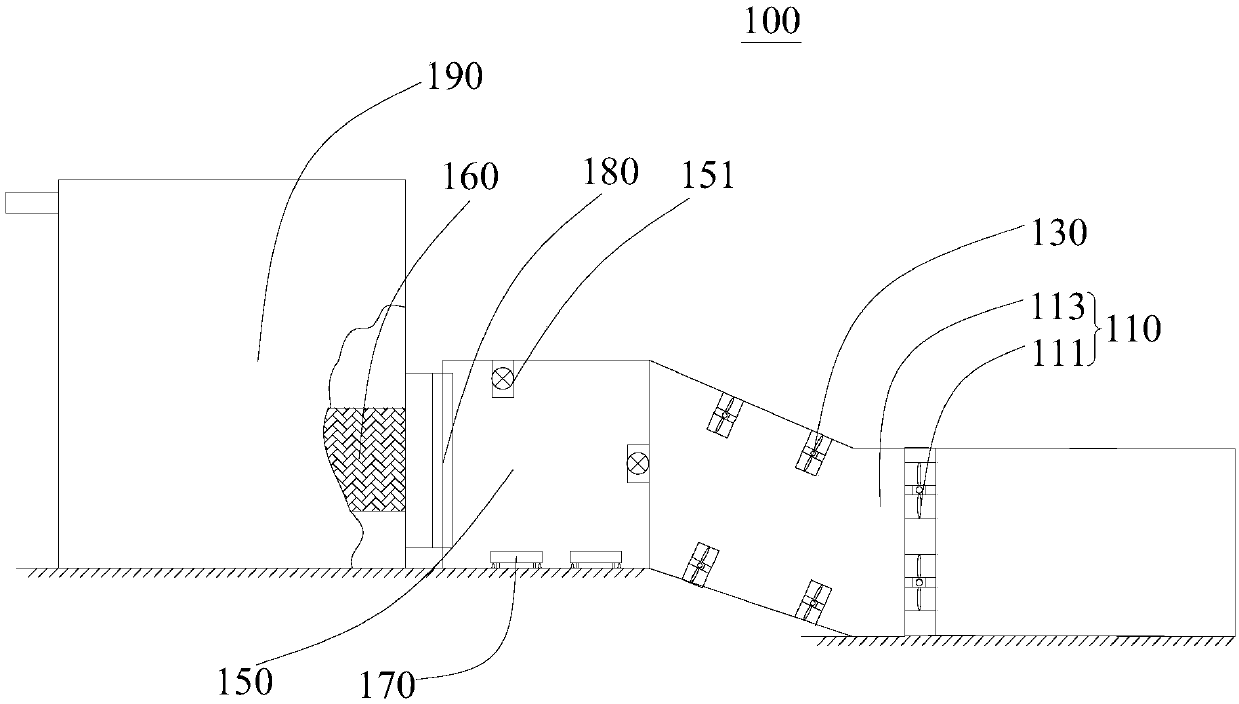

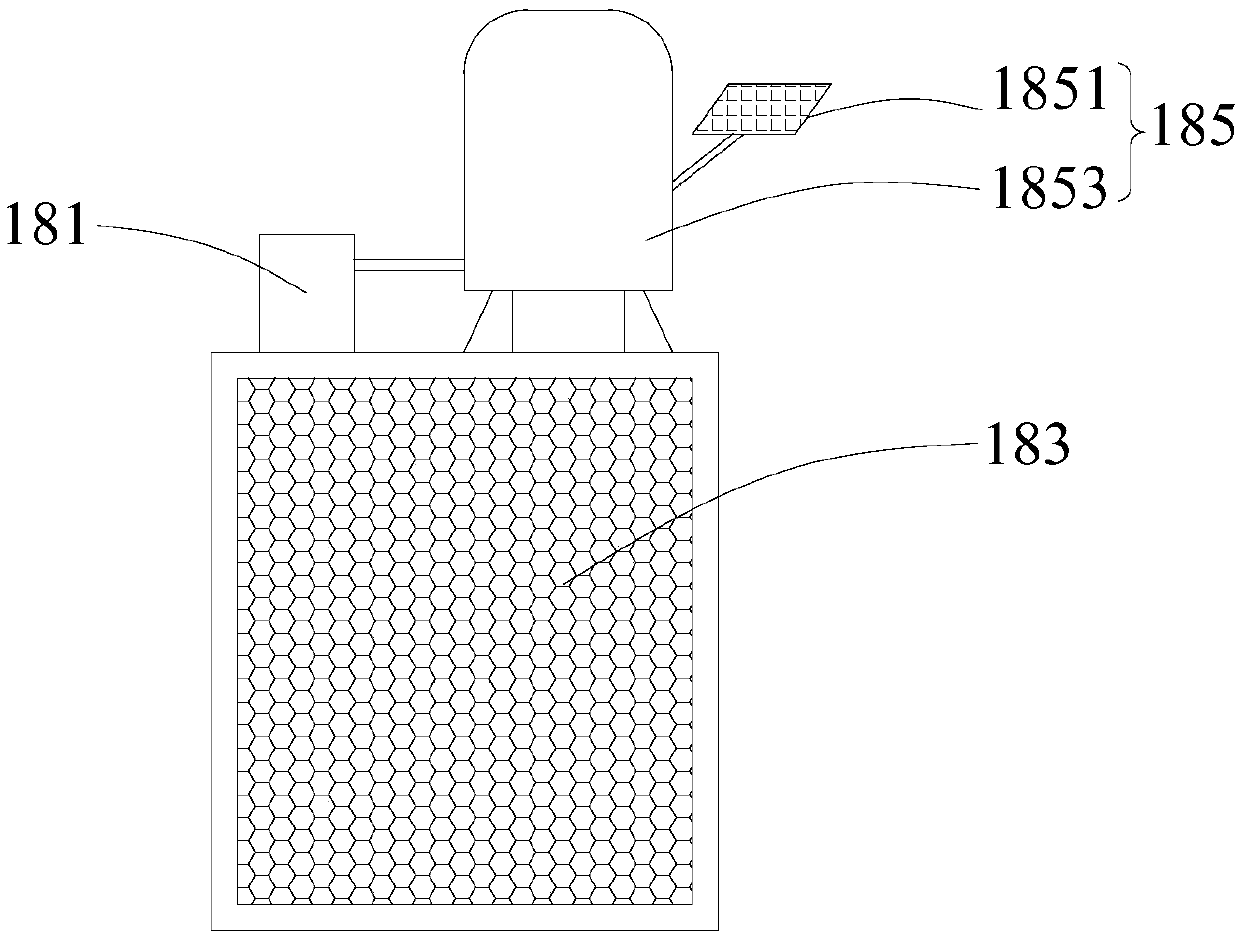

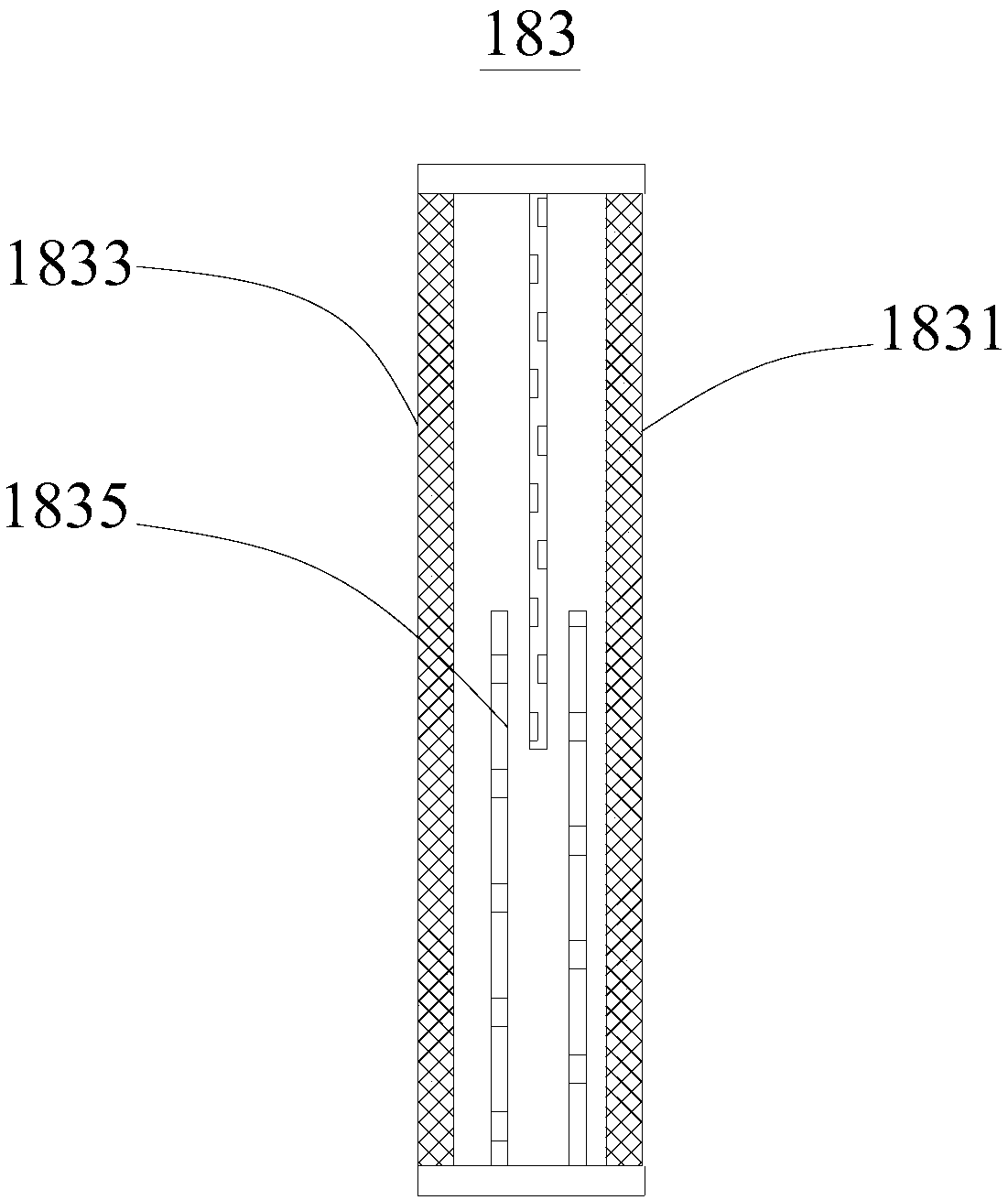

[0036] refer to figure 1 , the present embodiment provides a tail gas recovery and reuse system 100, which is used to install the tail gas discharge port of the breeding house and dry silage. Room 150, temperature control system 160, multiple feed turning devices 170, filter device 180 and constant temperature ecological greenhouse 190, multiple feed turning devices 170 are accommodated in drying room 150, constant temperature ecological greenhouse 190 is connected with drying room 150, The drying room 150 communicates with the tail gas collection device 110 through the air induction device 130, and the tail gas collection device 110 is installed at the tail gas discharge port of the breeding house, so that the tail gas produced by the breeding house enters the drying room through the tail gas collection device 110 and the air introduction device 130 150, and then enter the constant temperature ecological greenhouse 190.

[0037] In this embodiment, the drying room 150 also h...

no. 2 example

[0058] see Figure 6 , the present embodiment provides a tail gas recovery type farm 200, including a breeding room 210, a feed room 230, a temperature control system 160, a temperature measuring device (not shown) and a tail gas recycling system 100, and the temperature control system 160 is set In the breeding house 210 , the breeding house 210 is connected with the tail gas recycling system 100 . The feed room 230 is arranged beside the drying room 150 and is connected with the drying room 150 and the constant temperature ecological greenhouse 190 through a section road. The basic structure, principle and technical effects of the tail gas recovery and reuse system 100 are the same as those of the first embodiment. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0059] There are multi-layer breeding rooms in the breeding room 210, and breeding cages are set up in each layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com