Supported metal catalyst and preparation method and application thereof

A metal catalyst and a supported technology are applied in the field of supported metal catalysts and their preparation to achieve the effects of good stability, high conversion rate and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

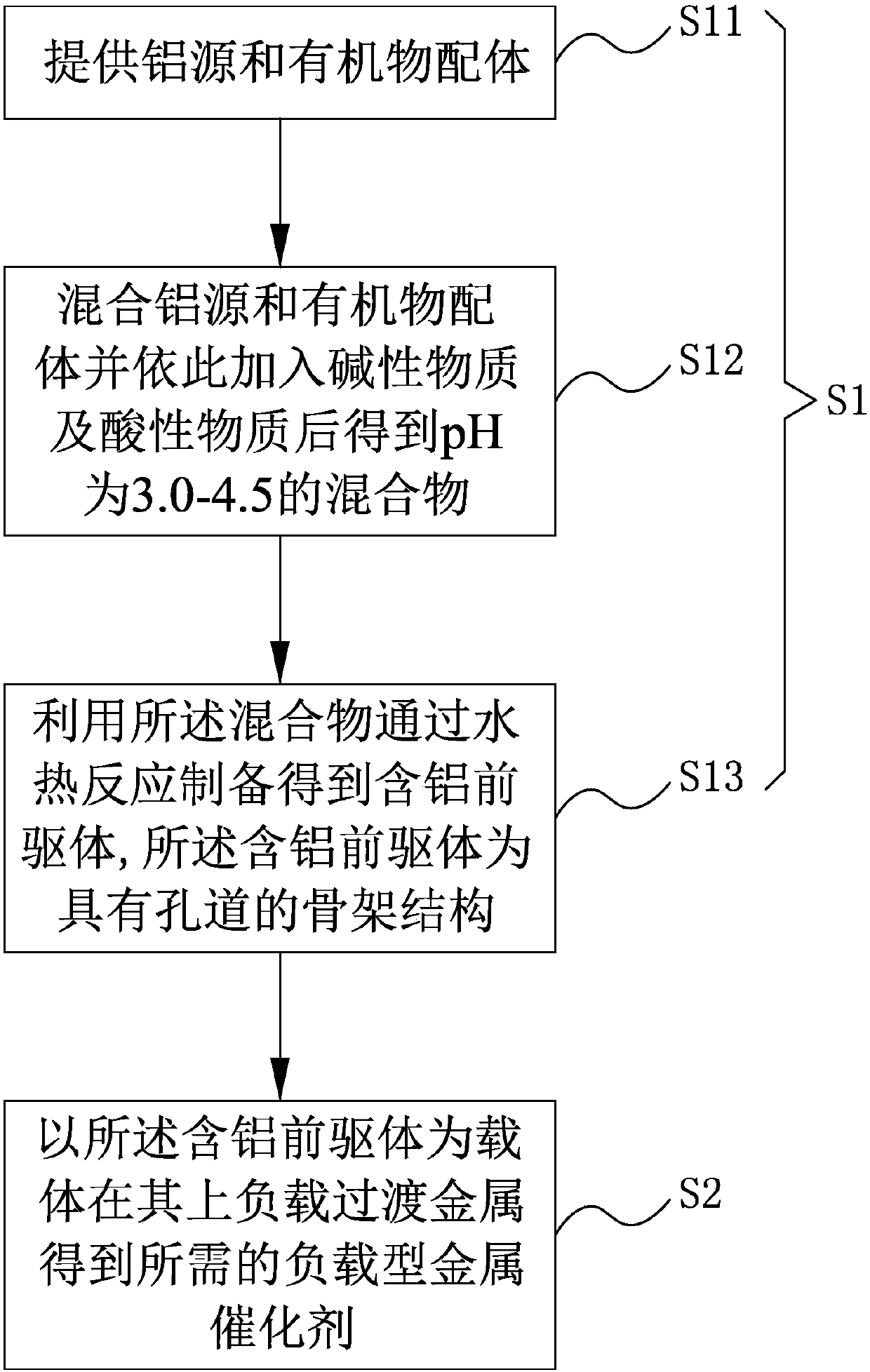

[0025] like figure 1 Shown, a kind of preparation method of supported metal catalyst comprises:

[0026] Step S1: preparing an aluminum-containing precursor, wherein the aluminum-containing precursor has a framework structure containing channels, specifically, the aluminum-containing precursor is a metal-organic framework compound having a channel structure;

[0027] Step S2: using the aluminum-containing precursor as a carrier to support transition metals on it and calcining at high temperature to obtain the desired supported metal catalyst.

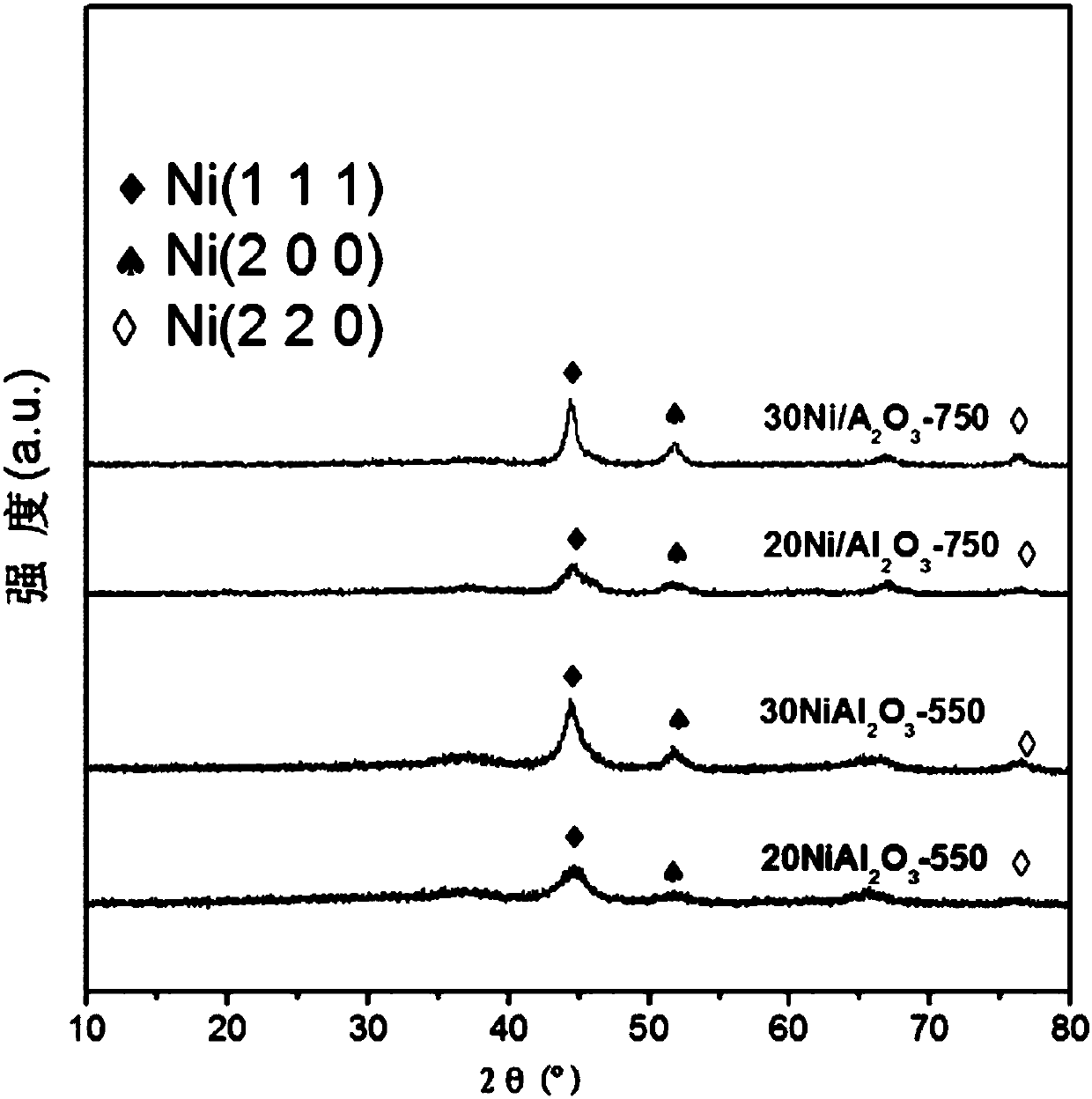

[0028] Wherein, the particle size of the transition metal supported on the obtained supported metal catalyst is 2-15nm, and the loading mass fraction of the transition metal is 10-40%.

[0029] Preferably, the supported metal catalyst is an alumina supported metal catalyst.

[0030] Described step S1 comprises the following steps:

[0031] Step S11: providing an aluminum source and an organic ligand;

[0032] Step S12: mixing the al...

Embodiment 2

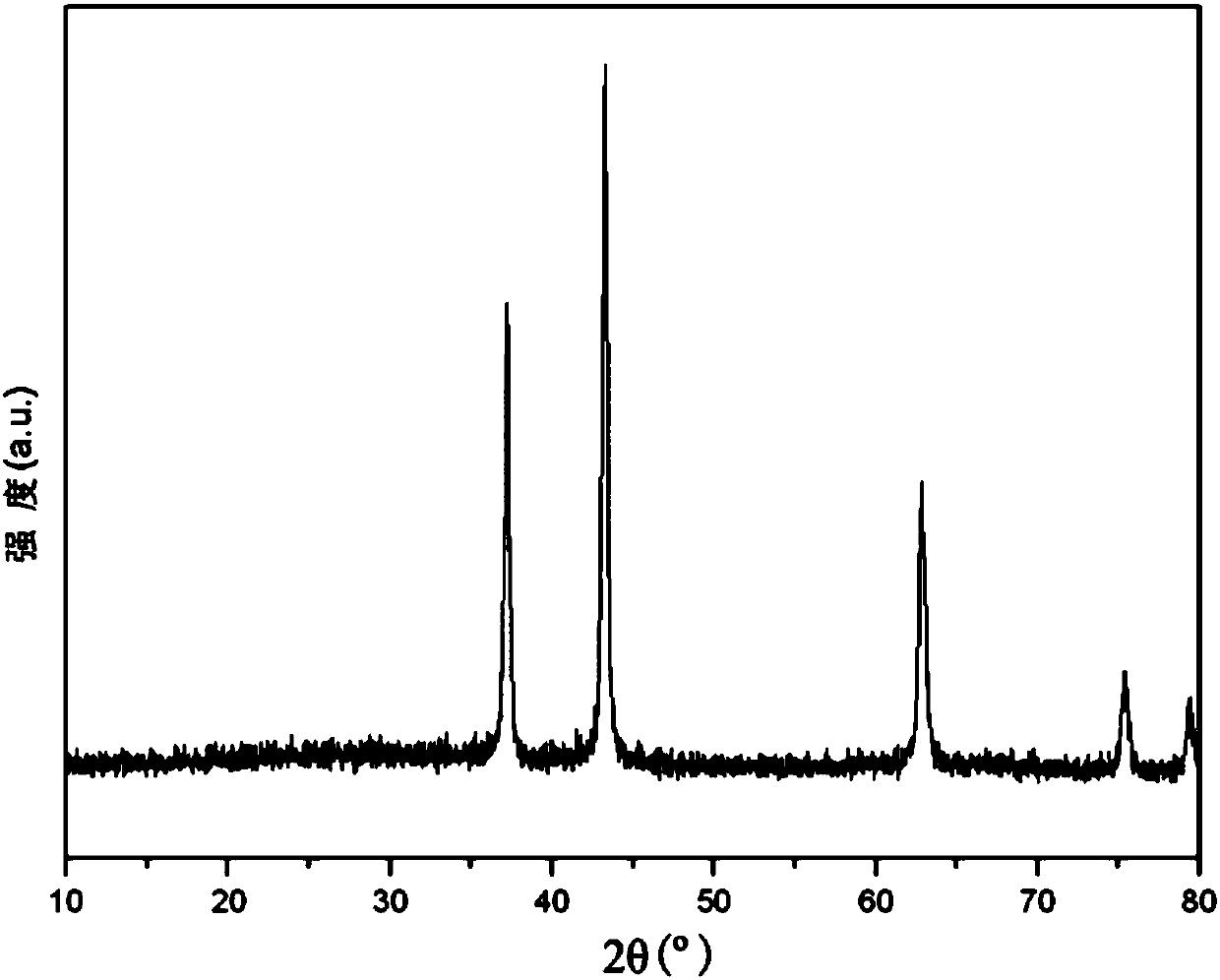

[0103] A supported metal catalyst, which is prepared through the preparation method of a supported metal catalyst provided in Example 1. The supported metal catalyst includes a carrier and a metal loaded on the carrier, the carrier is an aluminum-containing precursor, which has a skeletal structure of pores, and the diameter of the pores is 1-5nm; the metal is a transition metal, which The particle size is 2-15nm. For the structure of the supported metal catalyst and the performance test related to the metal loading, please refer to the description in Example 1, which will not be repeated here.

[0104] Compared with the prior art, the supported metal catalyst provided by the present invention uses an aluminum-containing precursor with a skeleton structure as a carrier, and the diameter of the channel is 1-5nm, and the particle size of the transition metal on it is 2-15nm , the transition metal is an active component of the supported metal catalyst. Due to the small diameter...

Embodiment 3

[0107] An application of a supported metal catalyst, applying the above-mentioned supported metal catalyst to synthesis gas to methane, has the advantages of high conversion rate and selectivity, and the conversion rate of CO can reach up to 96%, CH 4 Selectivity can reach up to 89%.

[0108] Compared with the prior art, the supported metal catalyst provided by the present invention adopts an aluminum-containing precursor with a skeletal structure containing pores as a carrier, and the diameter of the pores is 1-5 nm, and the particle size of the transition metal loaded on it is 2-15nm, the transition metal is the active component of the supported metal catalyst. Due to the small diameter of the pores on the carrier, the dispersion of the transition metals loaded on it can be guaranteed, and the transition metals with small particle sizes can be obtained, which has good activity, so that the supported metal catalyst can have conversion rate and selectivity. The advantage of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com