Stamping die device of motor stator piece

A stator sheet and stamping die technology, applied in the field of stamping die devices, can solve the problems of easy operation errors, unsafe use, low efficiency, etc., and achieve the effects of good safety, improved work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

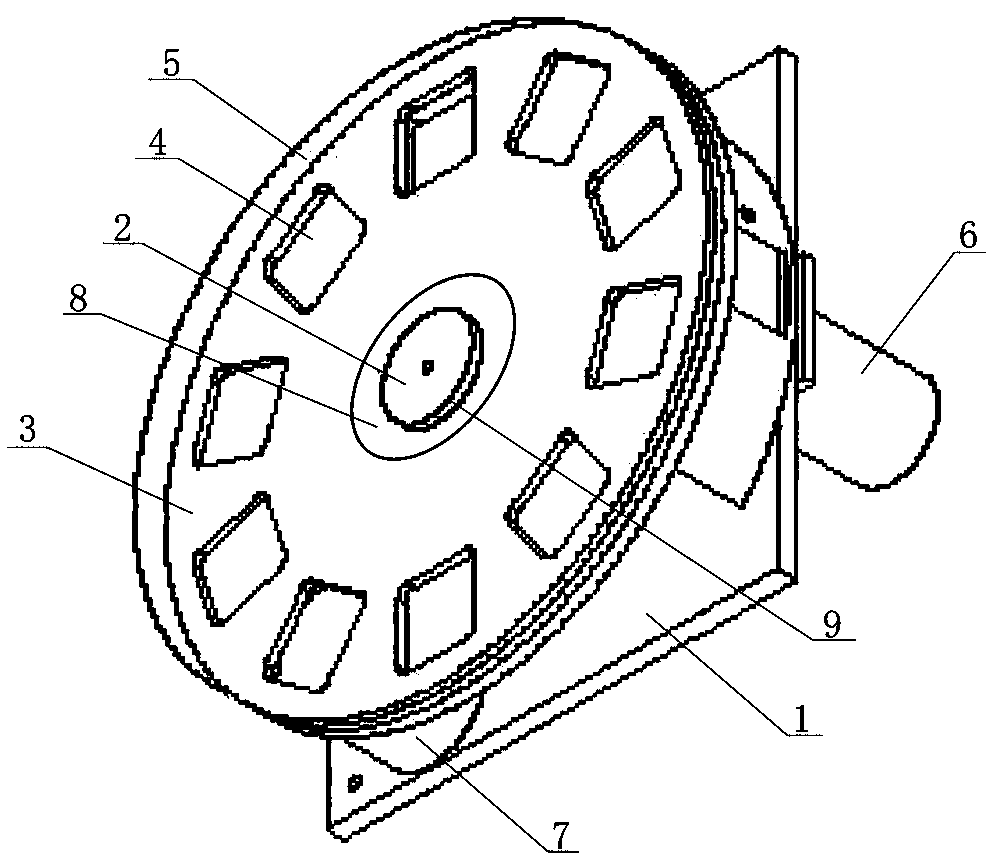

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a stamping die device of a motor stator sheet according to the present invention includes a base 1, and a rotating shaft 2 perpendicular to the base 1 is installed in the middle of the base 1 through a shaft seat, and a supporting shaft 2 is installed in the shaft seat Bearing; the upper end of the rotating shaft 2 is fixed with a circular punching plate 3, and several troughs 4 are evenly opened on the punching plate 3, and the periphery of the punching plate 3 is provided with protrusions, which can drive the motor The stator sheet is positioned on the ring edge 5 above the punching plate 3, and the bottom of the base 1 is equipped with a stepping motor 6, and the stepping motor 6 is fixed by a reduction gear box and a rotating shaft extending under the base 1. The rotating shaft gears on the rotating shaft are meshed and connected; when in use, the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com