Centrifugal wind wheel forming die

A centrifugal wind wheel and forming mold technology, applied in the direction of perforation tools, manufacturing tools, metal processing equipment, etc., can solve the problems of many processing steps, easy deformation, low production efficiency, etc., to reduce processing steps, improve product quality, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

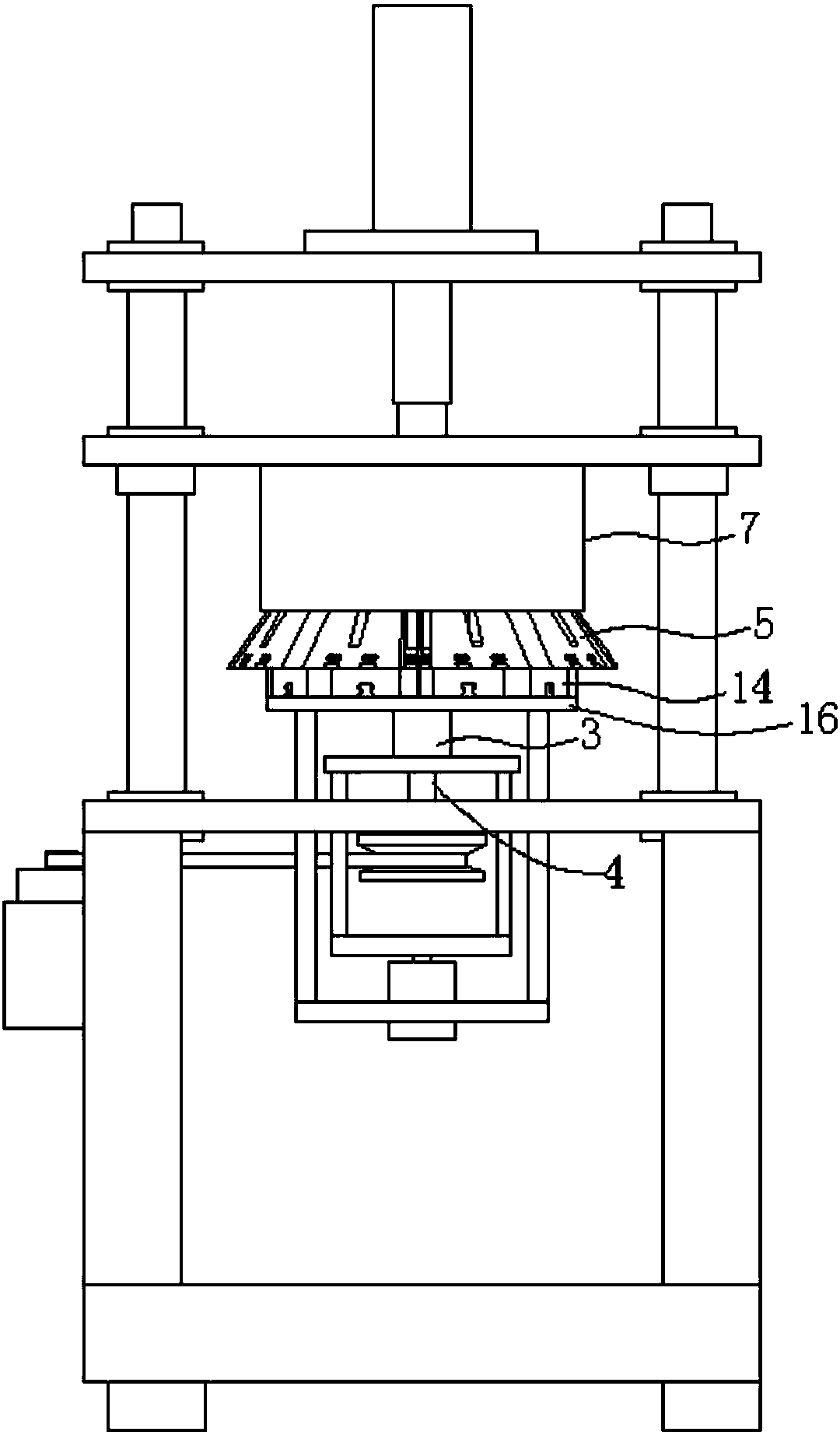

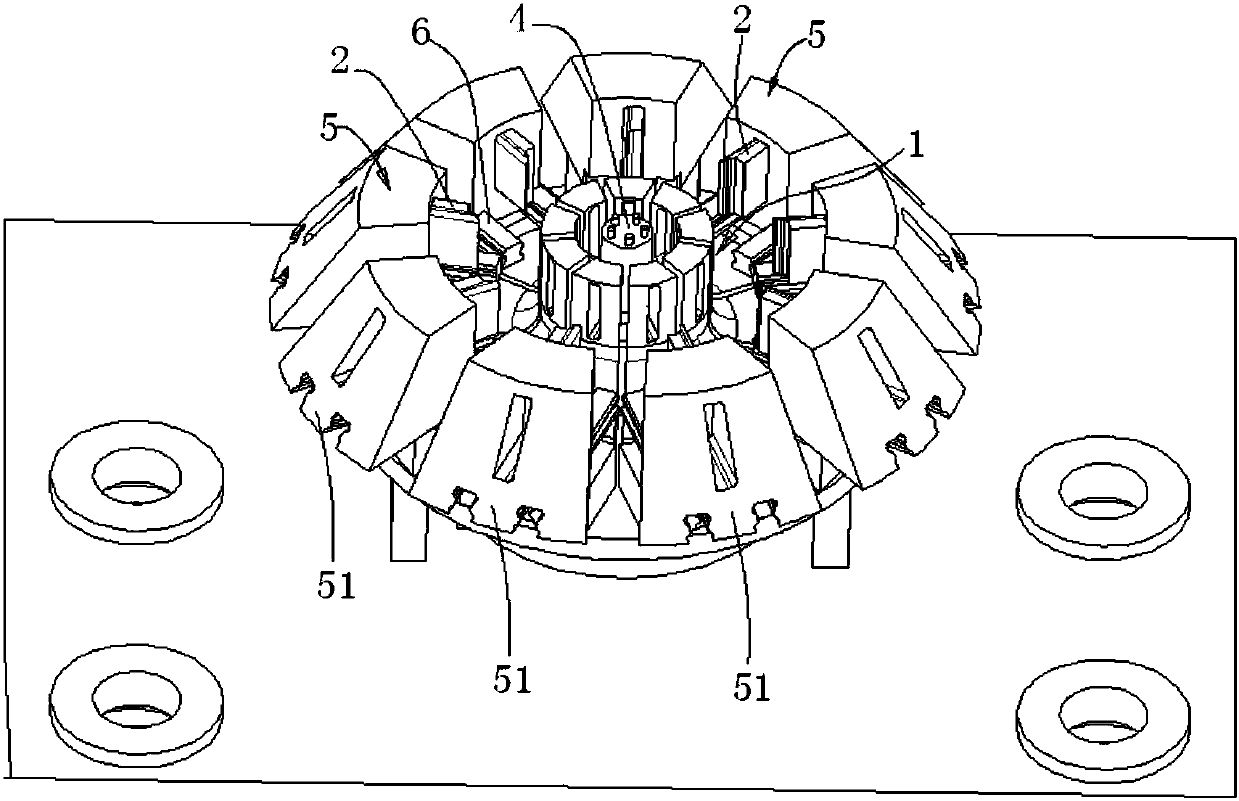

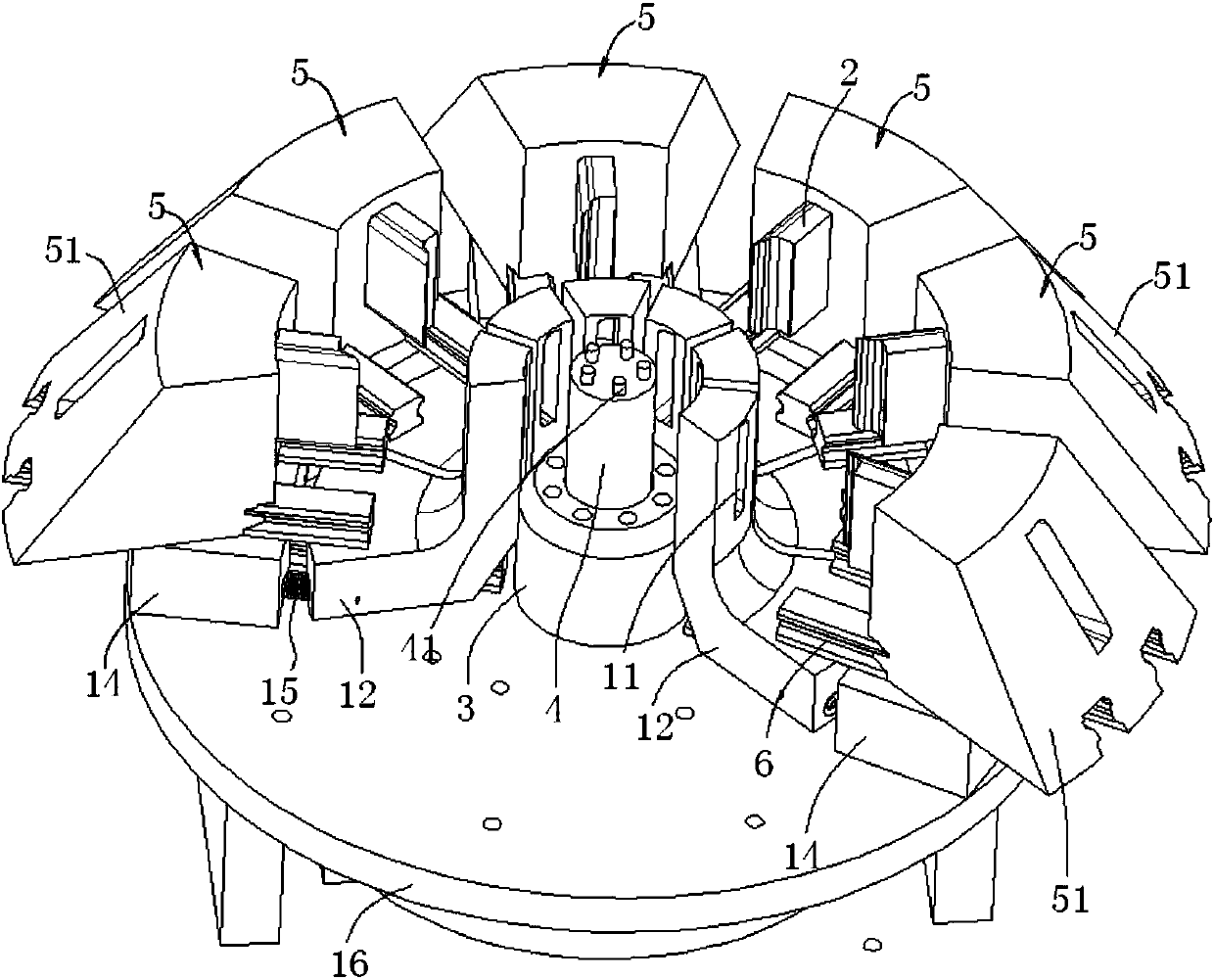

[0020] Figure 1~4 A mold for forming a centrifugal wind wheel according to an embodiment of the present invention is schematically shown.

[0021] Such as Figure 1~3 As shown, the centrifugal wind wheel molding die includes a core 1, a plurality of punches 2, an expanding core 3, a positioning shaft 4, an outer slider 5, an outer slide rail 6 and a push sleeve 7. The mold core 1 is provided with holes 11 corresponding to the punches 2 , and a plurality of punches 2 are arranged in a ring and evenly distributed on the outside of the mold core 1 . The number of punches 2 is not less than six. In this embodiment, there are nine punches 2 .

[0022] The mold core 1 includes a plurality of expansion sleeves 12 arranged circularly in the horizontal direction and evenly distributed on the outside of the expansion core 3 . Up core 3 is vertically arranged. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap