Twist drill

A twist drill and drill shank technology, which is applied in twist drills, drill repairing, drilling tool accessories, etc., can solve the problems of waste of coolant and the influence of the operator's line of sight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

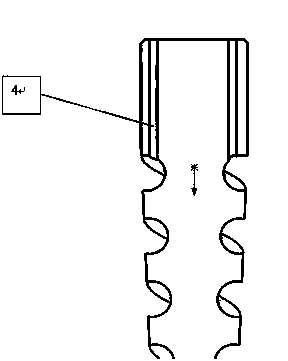

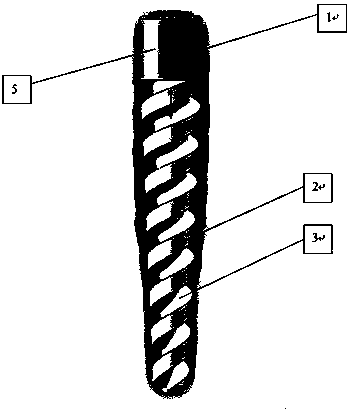

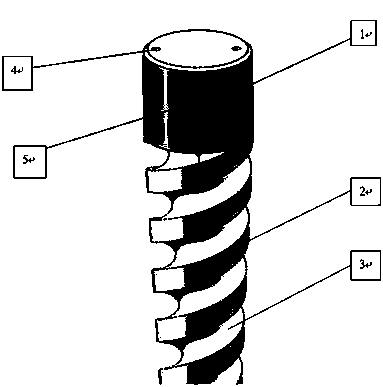

[0012] As shown in the figure, the twist drill includes a drill handle (1) and a drill body (2). The drill handle (1) is set above the drill body (2) and connected with the drill body (2). The clamps on both sides of the conical section The angle is 135°, there are several helical cutting edges on the cutter head, and the helix angle is 20°, and a spiral chip removal groove (3) is formed between the cutting edges, which is conducive to chip removal.

[0013] The upper end of the drill shank (1) is provided with two cooling grooves (4). The two cooling grooves (4) are symmetrical to each other with the axis of the drill body (2) as the center. The cooling liquid groove (4) leads to the drain groove (3 ) on both sides. The abrasive layer (5) can increase the friction between the drill bit and the rotating shaft, so that the drill bit can be clamped more firmly. The outer surface of the drill shank (1) is provided with a frosted layer (5) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com