Disassembling and assembling tool for camshaft bush of diesel engine

A technology for camshafts and diesel engines, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of poor versatility of disassembly tools and easy damage to the surface of camshaft bushings, etc., achieve strong versatility, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

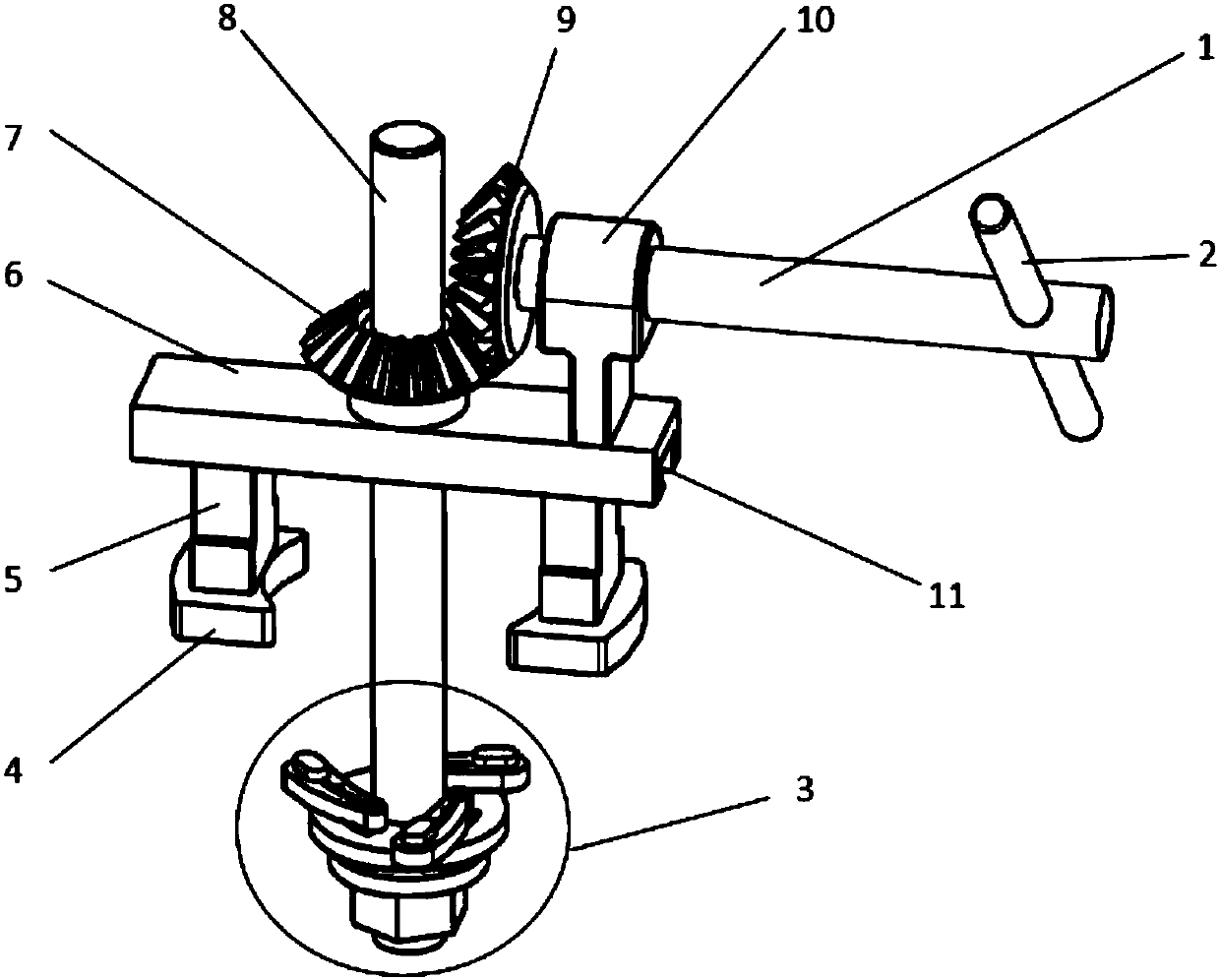

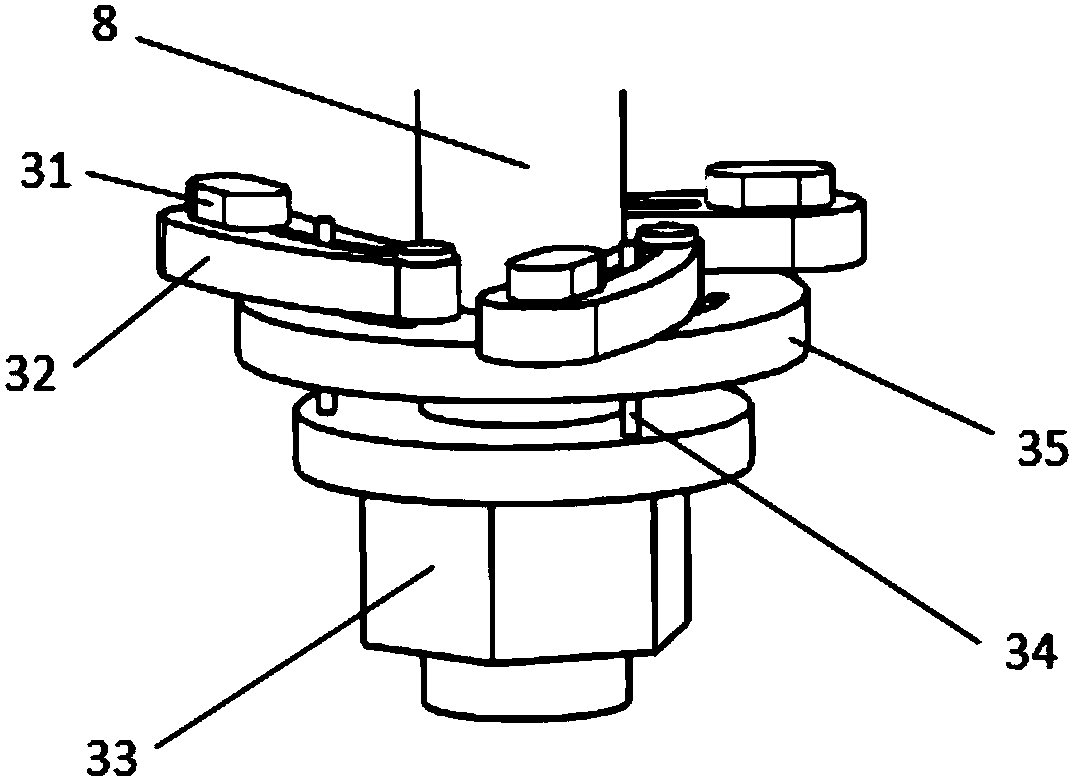

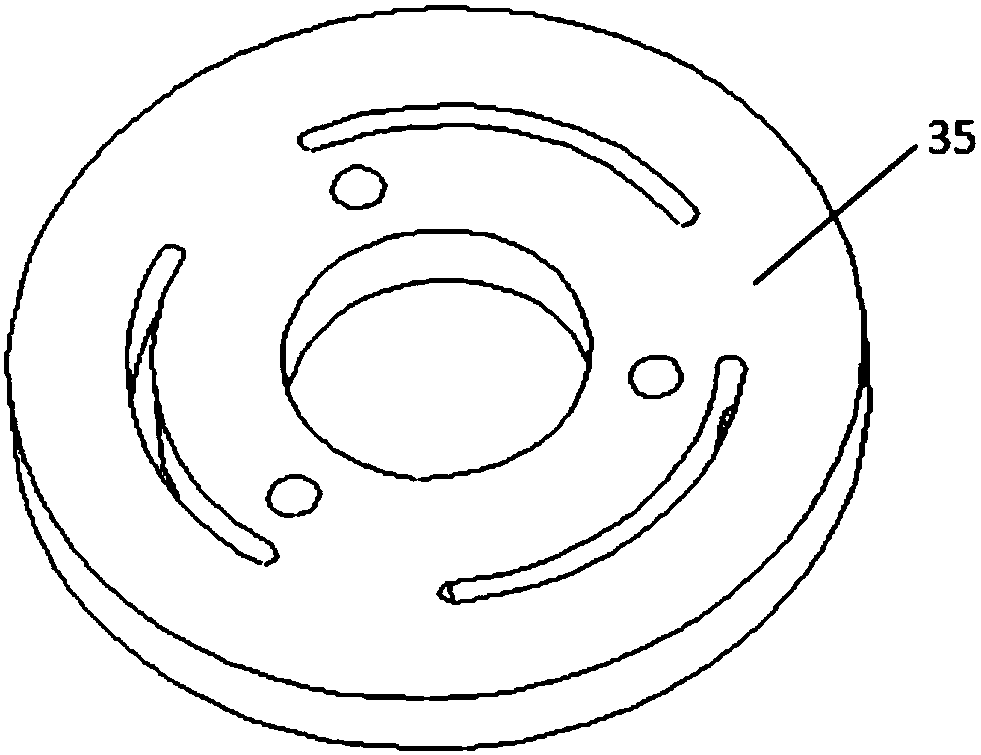

[0024] Such as figure 1 As shown, a camshaft bushing removal tool for a diesel engine includes a transmission shaft 1, a handle 2, a claw mechanism 3, a foot pad 4, a supporting foot 5, a bracket 6, a driven bevel gear 7, a transmission screw 8, and a driving Bevel gear 9, support seat 10, one end of the transmission shaft 1 is connected to the handle 2, and the other end passes through the support seat 10 to connect with the driving bevel gear 9, the support seat 10 is fixed on the support 6, and the movable bevel gear 7 It is connected with the middle part of the bracket 6 and meshed with the driving bevel gear 9. One end of the transmission screw 8 passes through the middle part of the bracket 6 and is connected with the driven bevel gear 7, and the other end is connected with the claw mechanism 3. The upper part of the supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com