Monorail roadway type stacking lifting device

A lifting device and roadway-type technology, which is applied in the field of single-rail roadway-type stacking lifting devices, can solve the problems of strengthening the transportation roadway, exhaust gas pollution, and restrictions on the transportation of overweight equipment, and achieve the effect of low noise and ensuring air cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

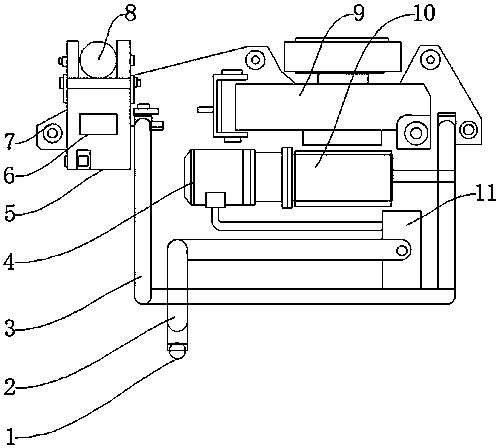

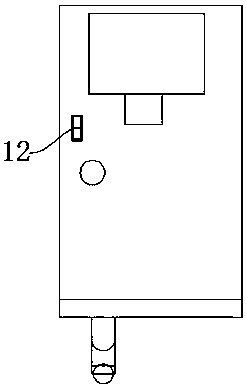

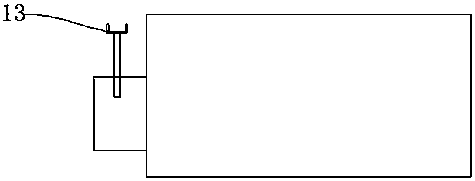

[0031] Such as Figure 1-Figure 3 As shown, a single-track roadway type stacking lifting device includes a bottom moving roller 1, a diesel drive motor 4, a lifting wire rope 8 and a control switch 12, a roller lifter 2 is installed above the bottom moving roller 1, and a roller lifter 2 is installed above the bottom moving roller 1. A hoisting device housing 3 is installed, a diesel drive motor 4 is installed above the hoisting device housing 3, a lifting control box 5 is arranged above the diesel drive motor 4, and an operation control panel 6 is installed above the lifting control box 5. Side reinforcing ribs 7 are installed above the control panel 6, and a lifting wire rope 8 is connected above the side reinforcing ribs 7. An exhaust gas recovery device 9 is installed on the right side of the lifting steel wire rope 8, and a motor reduction box 10 and a motor reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com