A kind of high modulus rubber asphalt mixture and preparation method thereof

A rubber asphalt, high modulus technology, applied in the field of road engineering, can solve the problems of poor high temperature resistance of concrete pavement, large emission of harmful gases, poor thermal storage stability, etc., achieve ultra-long service life, improve anti-rutting ability, fatigue good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

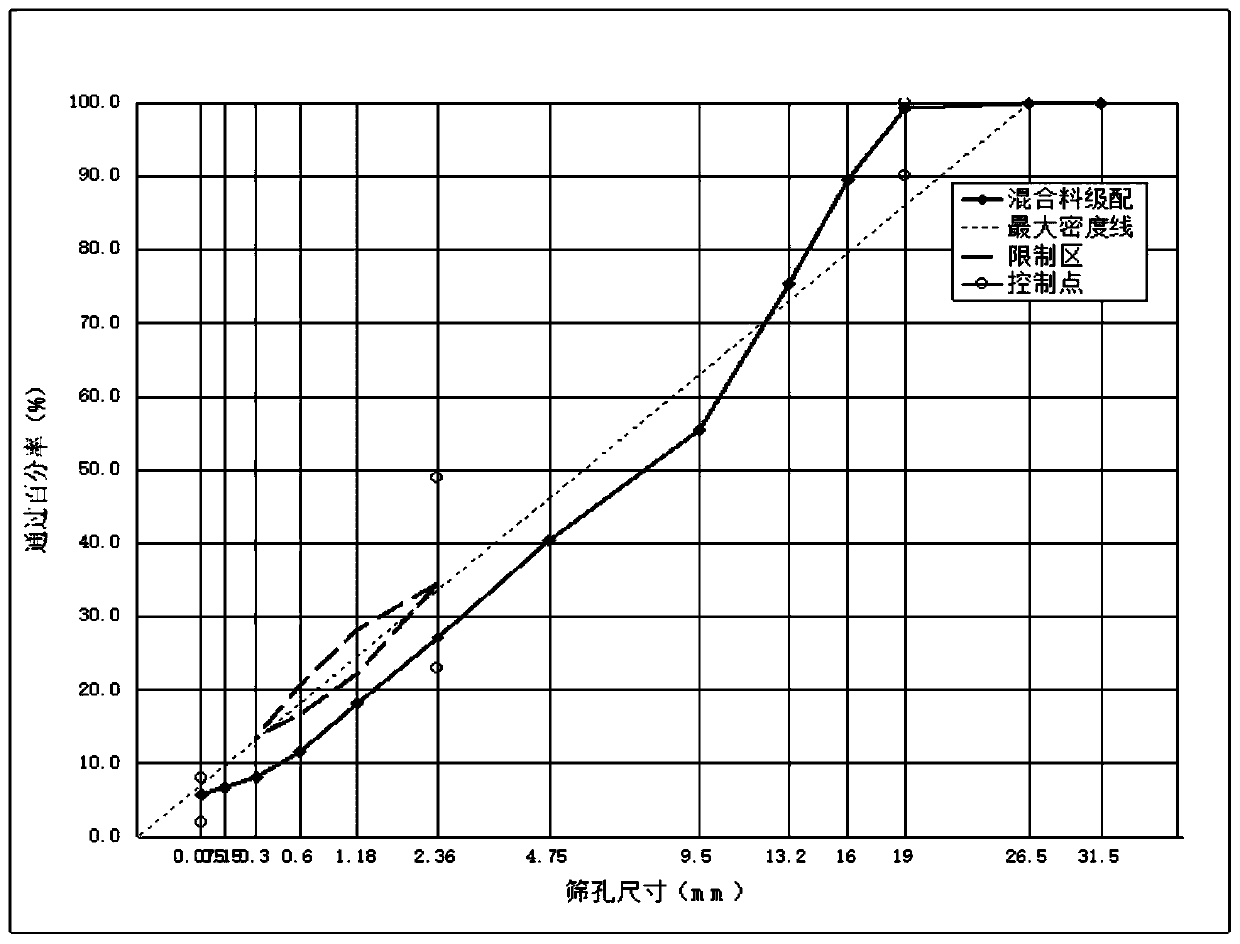

Embodiment 1

[0026] The project overview of this embodiment is: the test section of the high modulus rubber asphalt mixture HMAC-20 is selected at the lower layer of the special road in the Sheping Line Mining Area, Langxi County, Xuancheng City, Anhui Province. The vehicle speed is 60Km / h, and the traffic load is mainly stone transport vehicles with a total weight of more than 120t. The average daily traffic load is 40,000 tons. The pavement structure adopts: 4cm industrial stable rubber asphalt SUP-13+6cm high modulus rubber asphalt mixture Material HMAC-20+1cm rubber asphalt stress absorbing layer. The lower layer adopts the high modulus rubber asphalt mixture HMAC-20 of the present invention.

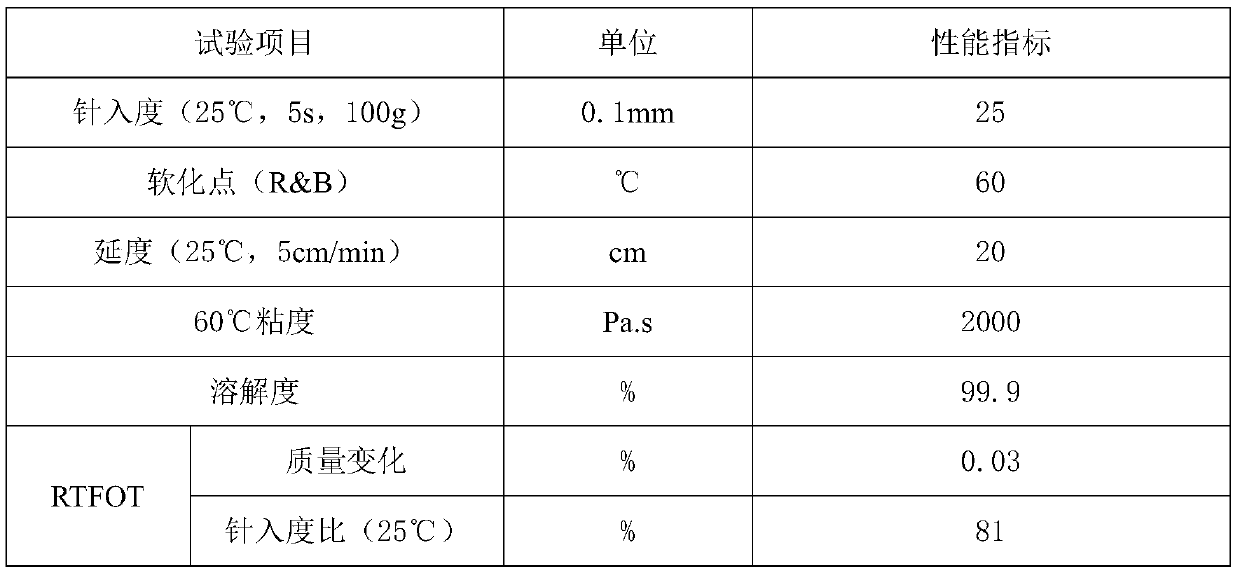

[0027] The hard asphalt used in the test road is TNH-25 straight road petroleum asphalt produced by Jiangsu Tiannuo Road Material Technology Co., Ltd., and the performance indicators are shown in Table 1.

[0028] Table 1 Performance indicators of TNH-25 hard asphalt

[0029]

[0030] The w...

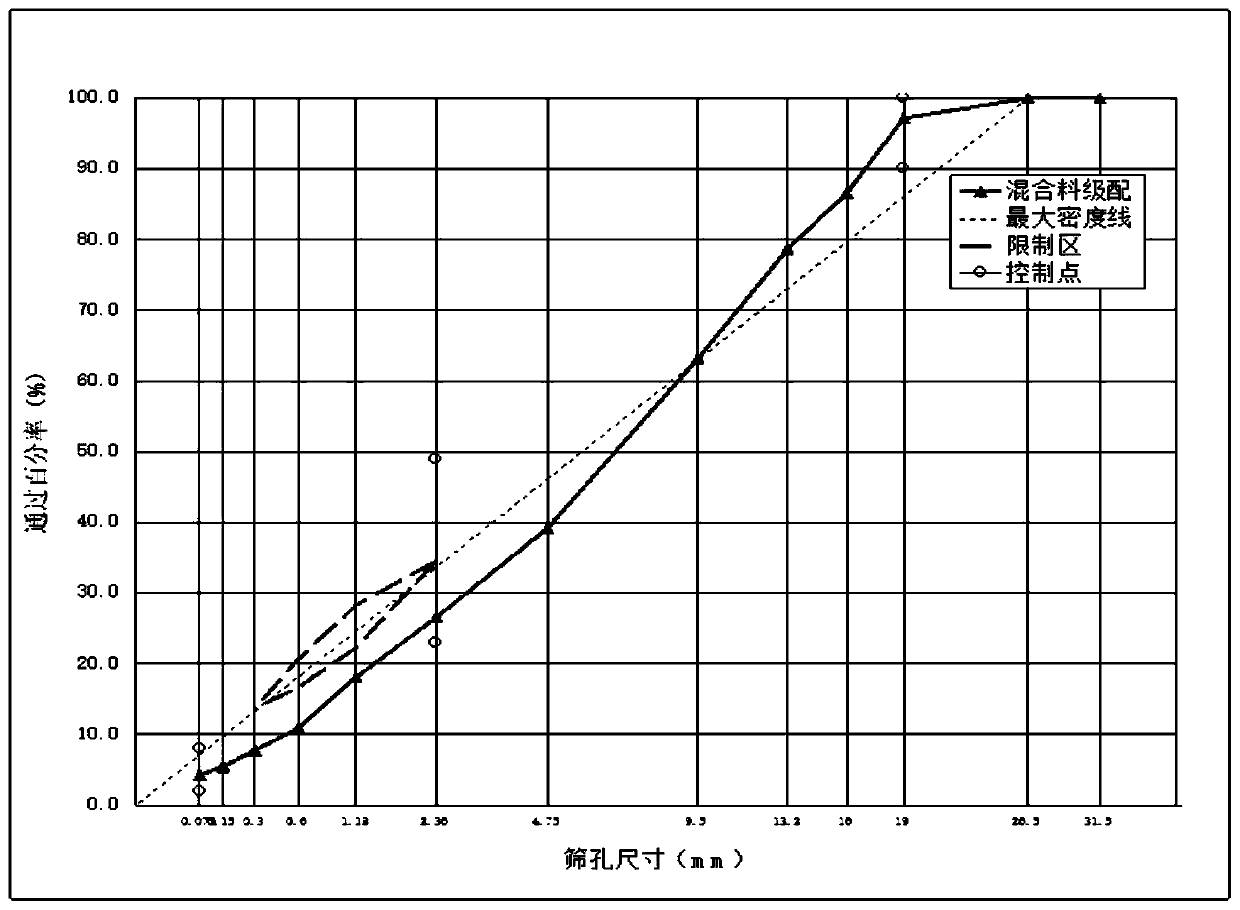

Embodiment 2

[0053] The project overview of this embodiment is: the high modulus rubber asphalt mixture HMAC-20 test section is selected in the middle surface course of the Jiangsu section of the Xuzhou-Mingguang Expressway, with a total length of 800 meters. The project adopts expressway standards, two-way four-lane, and the design speed 120Km / h, the pavement structure adopts: 4cm asphalt mixture (SMA-13) + 6cm asphalt mixture (HMAC-20) + 8cm asphalt mixture (SUP-25). The middle surface layer adopts the high modulus rubber asphalt mixture HMAC-20 of the present invention.

[0054] The hard asphalt used in the test road is TNH-35 straight road petroleum asphalt produced by Jiangsu Tiannuo Road Material Technology Co., Ltd., and the performance indicators are shown in Table 6.

[0055] Table 6 TNH-35 hard asphalt performance index

[0056]

[0057]

[0058] Waste tire rubber powder is commercially available 60-mesh rubber powder with a carbon black content of 30.1%, ash content of 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com