High-strength baking-free brick prepared from electric furnace ferronickel slag and preparation method of high-strength baking-free brick

A nickel-iron slag and high-strength technology, which is applied in the field of high-strength unburned bricks and its preparation, can solve the problems of high cost, land occupation, and large amount of slag discharge, and achieve the effects of reducing raw material costs, easy production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

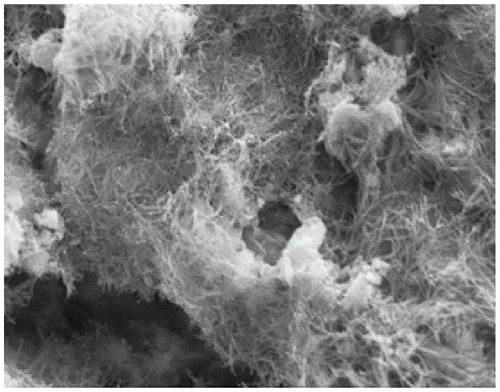

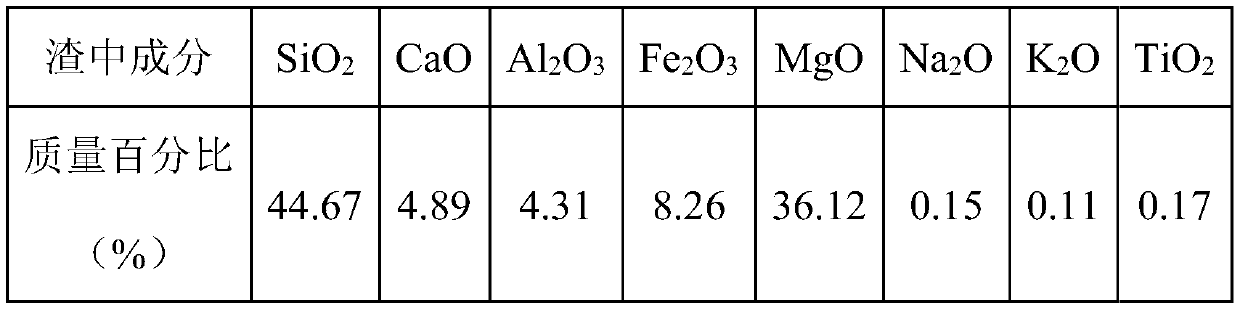

Image

Examples

Embodiment 1

[0023] Preparation

[0024] Using ferronickel slag, cement, anhydrous gypsum and calcium hydroxide as raw materials, the ferronickel slag is finely ground to make the specific surface area reach 450m 2 / kg, the mass ratio of cement and ferronickel slag in the raw material is 4:1. 1% of the total mass of anhydrite and 1% of calcium hydroxide are externally prepared. Water with a mass fraction of 28% is added, fully stirred, then put into a grinding tool, and vibrated and pressed under a pressure of 20 MPa to obtain a green body. The green body was cured at room temperature in a closed workshop, and the brick body was kept moist for 28 days to prepare unburned bricks.

[0025] product performance

[0026] The compressive strength of unfired bricks prepared according to the above method is 29.79MPa, and the flexural strength is 6.37MPa.

Embodiment 2

[0028] Preparation

[0029] Using ferronickel slag, cement, anhydrous gypsum and calcium hydroxide as raw materials, the ferronickel slag is finely ground to make the specific surface area reach 500m 2 / kg, the mass ratio of cement and ferronickel slag in the raw material is 4:1. 1% of the total mass of anhydrite and 1% of calcium hydroxide are externally prepared. Water with a mass fraction of 28% is added, fully stirred, then put into a grinding tool, and vibrated and pressed under a pressure of 20 MPa to obtain a green body. The green body was cured at room temperature in a closed workshop, and the brick body was kept moist for 28 days to prepare unburned bricks.

[0030] product performance

[0031] The compressive strength of unfired bricks prepared according to the above method is 30.35MPa, and the flexural strength is 6.52MPa.

Embodiment 3

[0033] Preparation

[0034] Using ferronickel slag, cement, anhydrous gypsum and calcium hydroxide as raw materials, the ferronickel slag is finely ground to make the specific surface area reach 500m 2 / kg, the mass ratio of cement and ferronickel slag in the raw material is 5:1. 1% of the total mass of anhydrite and 1% of calcium hydroxide are externally prepared. Water with a mass fraction of 26% is added, fully stirred, then put into a grinding tool, and vibrated and pressed under a pressure of 20 MPa to obtain a green body. The green body was cured at room temperature in a closed workshop, and the brick body was kept moist for 28 days to prepare unburned bricks.

[0035] product performance

[0036] The compressive strength of unfired bricks prepared according to the above method is 34.68MPa, and the flexural strength is 6.94MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com