A depolymerization process and device for nanopowder

A nano-powder and process technology, applied in the field of mechanical manufacturing and processing, can solve problems such as poor depolymerization effect of nano-powder, and achieve the effects of improving compatibility, reducing cost, and increasing activation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

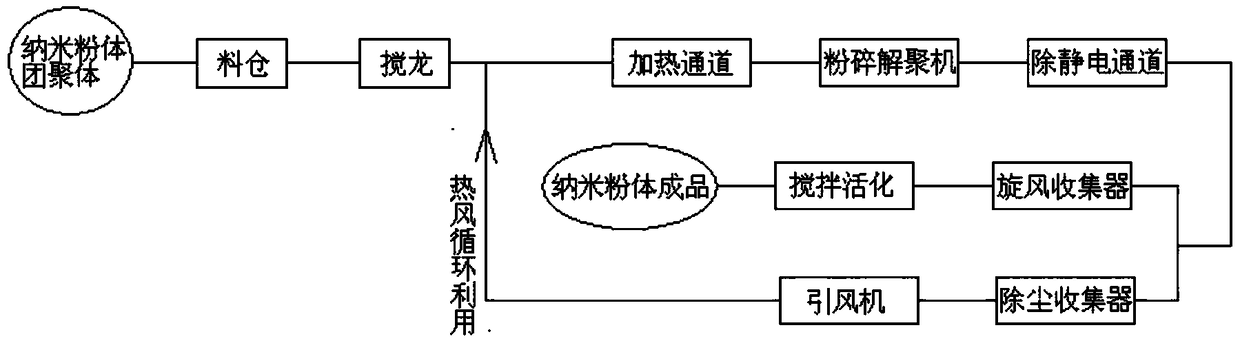

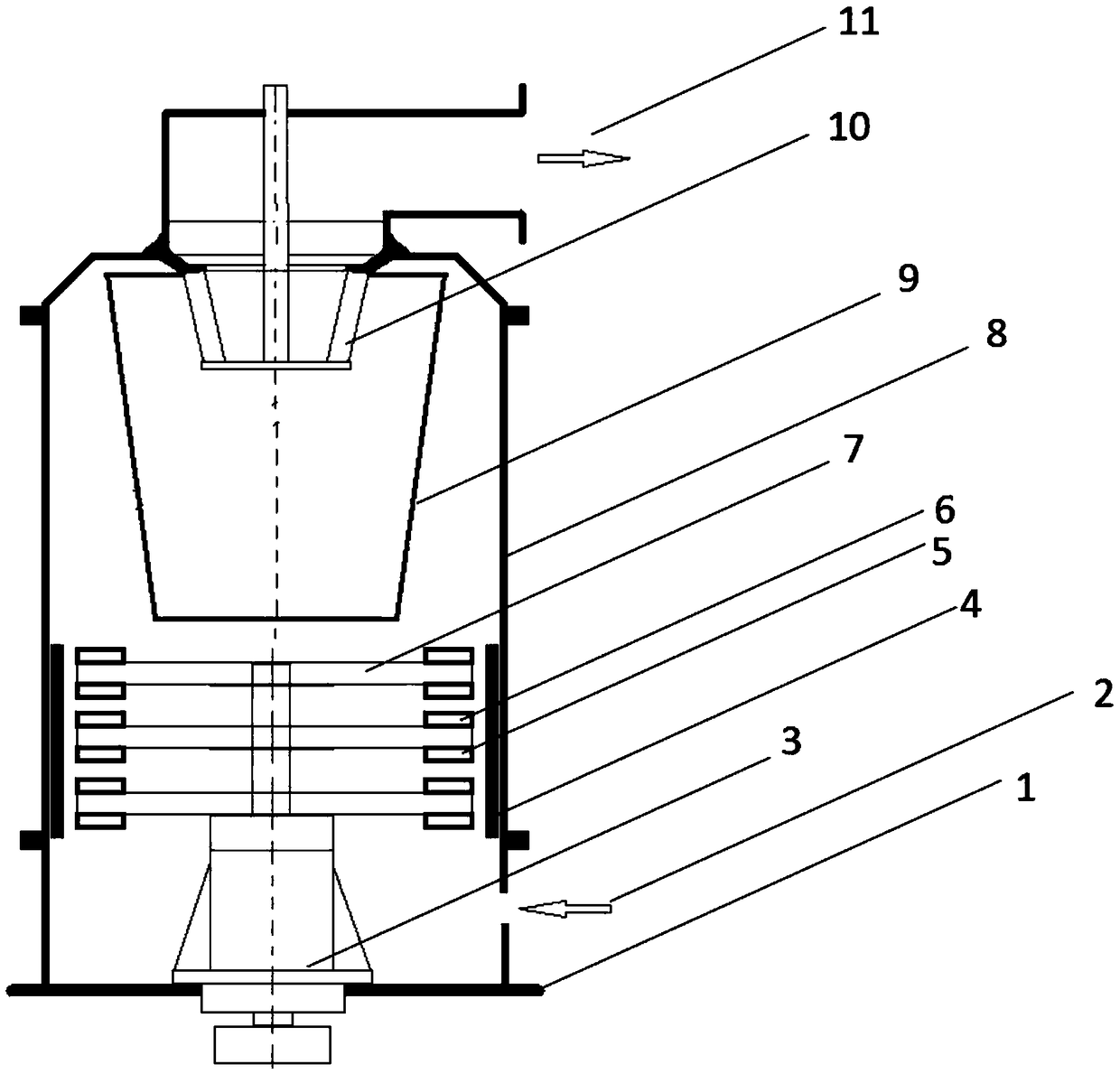

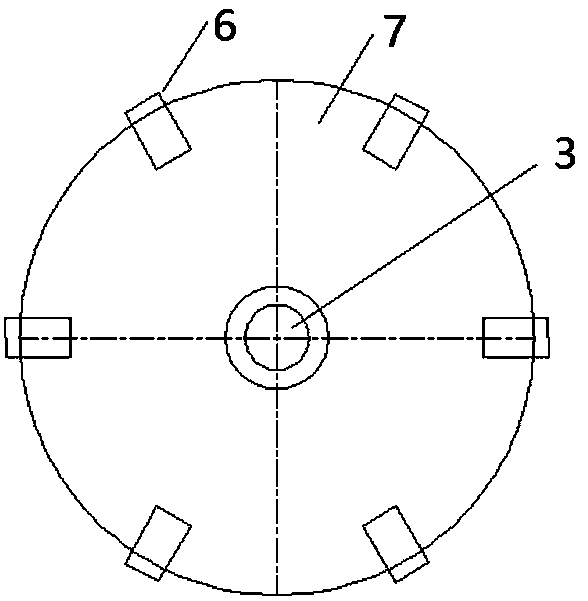

[0056] see figure 1 It is a flow chart of the depolymerization process of nano powder in the present invention, which includes the following steps: after the nano powder aggregate is stirred and heated, it is introduced into the pulverizing depolymerizer, and the depolymerized powder enters the cyclone collector, Adding an activator to the collected powder, stirring and activating to obtain depolymerized nano powder. By stirring and heating the agglomerates, the powder can be beneficial to the contact reaction with the surfactant at a higher temperature, and the agglomerates are impacted and broken up by the crushing and deaggregating machine, and the fine enough particles are sent into the cyclone collector Inside, followed by stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com