A strontium phosphate-based nano-assembled spherical anti-corrosion pigment

A nano-assembly and anti-corrosion pigment technology, applied in the field of material chemistry, can solve the problems that there are no research reports on the preparation of strontium phosphate-based nano-assembly spherical anti-corrosion pigments, and achieve the effects of stable structure, small particle size, and fixed chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

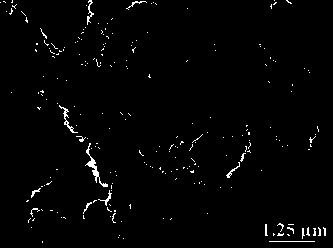

Embodiment 1

[0020] Prepare strontium nitrate and 0.8 mol / L sodium phosphate solutions with a concentration of 1.2 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 0.2 g of benzene to the strontium nitrate and sodium phosphate solutions respectively Triazole and 0.05g polyethylene glycol, stirred until fully dissolved. Place the strontium nitrate solution and the sodium phosphate solution on both sides of the egg membrane respectively. After reacting for 12 hours, take the precipitate, wash it with deionized water three times, put it in an oven, and dry it at 60°C for 12 hours to obtain the strontium phosphate base. Nano-assembled spherical anti-corrosion pigments. The overall diameter of the obtained strontium phosphate-based nano-assembled spherical anticorrosion pigment is about 2.5 μm, and the thickness of the nanoribbon assembled into the nano-assembled sphere is about 30 nm. The anti-corrosion pigment is added to the paint to make a pai...

Embodiment 2

[0022] Prepare strontium nitrate and 0.008mol / L sodium phosphate solutions with a concentration of 0.012 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 0.01 g of benzene to the strontium nitrate and sodium phosphate solutions respectively Triazole and 0.02g cetyltrimethylammonium bromide, stirred until fully dissolved. Place the strontium nitrate solution and the sodium phosphate solution on both sides of the egg membrane respectively. After reacting for 12 hours, take the precipitate, wash it with deionized water three times, put it in an oven, and dry it at 60°C for 12 hours to obtain the strontium phosphate base. Nano-assembled spherical anti-corrosion pigments. The overall diameter of the obtained strontium phosphate-based nano-assembled spherical anticorrosion pigment is about 3 μm, and the thickness of the nanobelt assembled into the nano-assembled sphere is about 22 nm. The anti-corrosion pigment is added to the paint to...

Embodiment 3

[0024] Prepare strontium nitrate and 0.0008mol / L sodium phosphate solutions with a concentration of 0.0012 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 0.001 g of benzene to the strontium nitrate and sodium phosphate solutions respectively And triazole and 0.0125g polyacrylamide, stir until it is fully dissolved. Place the strontium nitrate solution and the sodium phosphate solution on both sides of the egg membrane, react for 12 hours, take the precipitate, wash it with deionized water 3 times, put it in an oven, and dry it at 95°C for 1 hour to obtain the strontium phosphate base Nano-assembled spherical anti-corrosion pigments. The overall diameter of the obtained strontium phosphate-based nano-assembled spherical anticorrosion pigment is about 2.5 μm, and the thickness of the nanoribbon assembled into the nano-assembled sphere is about 20 nm. The anti-corrosion pigment is added to the paint to make a paint film. The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com