Steel pipe diameter expanding oil composition and use thereof

An oil composition, steel pipe diameter expansion technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of reducing the lubricating effect of diameter expansion oil, and achieve the effect of easy formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0034] Preparation of sulfurized fatty acid amide: add sulfurized fatty acid to the mixing tank, raise the temperature to 110°C, add triethanolamine continuously while stirring, the molar ratio is 1:1, and continue stirring and heating for 2 hours.

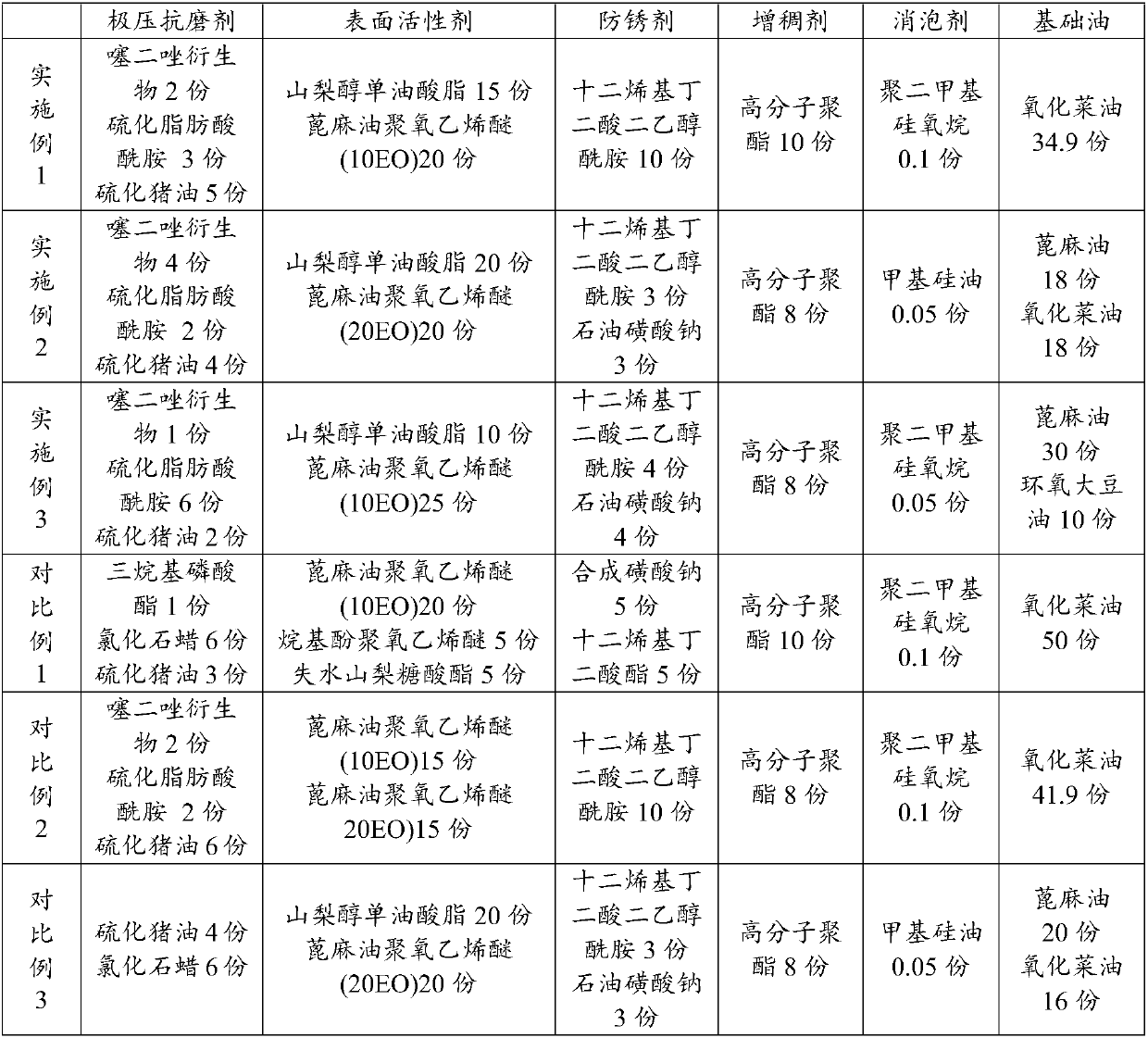

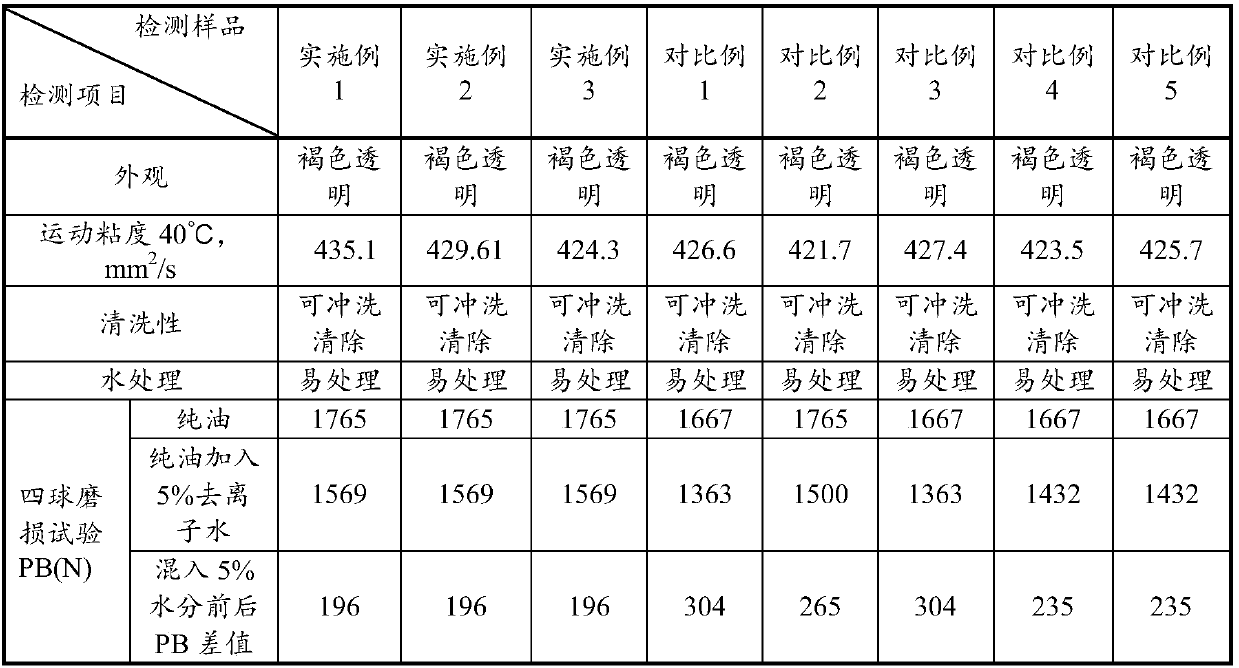

[0035] Put the base oil into the blending kettle, stir, heat up to 50°C and maintain at this temperature; add extreme pressure anti-wear agent, stir evenly; then add surfactant, stir evenly; finally add rust inhibitor and thickener, stir and Heating is stopped, the temperature is gradually lowered to room temperature, and stirring is stopped to obtain the composition. The type and amount of each component in the composition are specifically shown in Table 1.

Embodiment 1

[0037] The composition was prepared according to the document CN102031186A [Example 1]. Its composition is:

[0038] 35 parts of oxidized rapeseed oil; 3.9 parts of polyether with a molecular weight of 50,000; 3.5 parts of vulcanized lard; 10 parts of chlorinated paraffin; 5 parts of trialkyl phosphate; 2 parts; 12 parts of castor oil polyoxyethylene ether; 10 parts of dodecenyl succinate; 2 parts of sorbitan oleate; 12 parts of polyether with a molecular weight of 20,000; 0.1 part of methyl silicone oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com