Tobacco licorice aroma component and extraction method and application thereof

A technology for aromatizing components and extraction methods, which is applied in the field of licorice aromatizing components and its extraction, can solve the problems of licorice aromatizing components with many impurities and poor quality of aroma, achieve good aromatization effect and improve smoke aroma Quality, irritation and off-gassing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

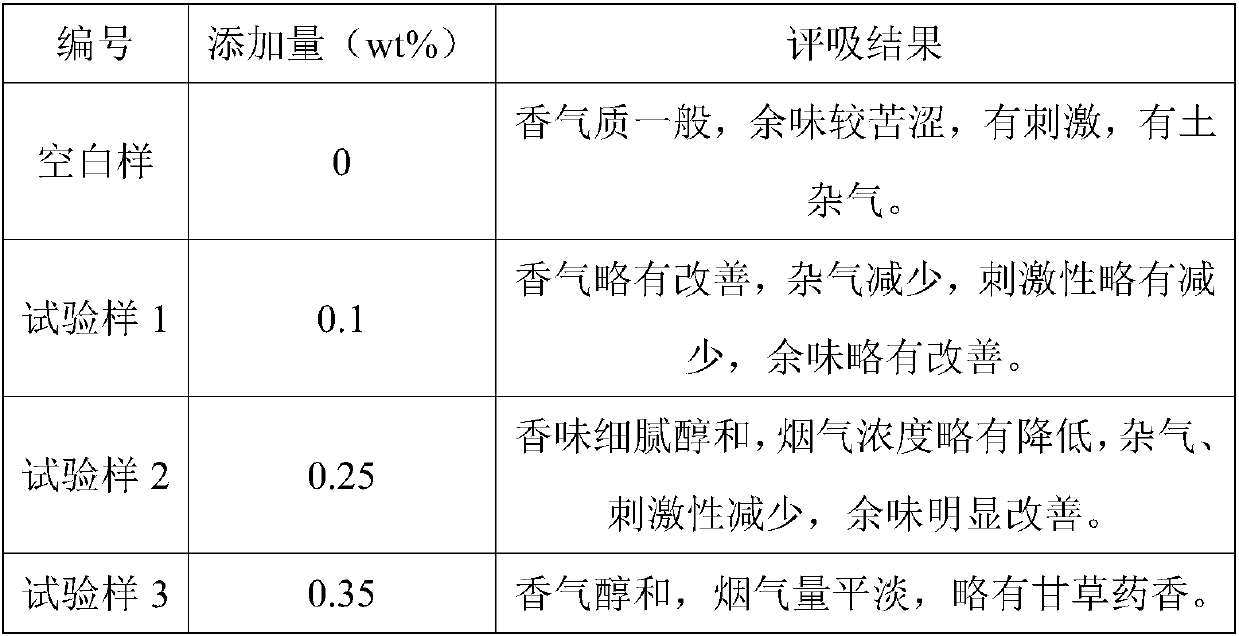

Examples

Embodiment 1

[0026] The extraction method of the aroma components of licorice for tobacco in the present embodiment adopts the following steps:

[0027] 1) Grind the naturally air-dried licorice, pass through a 100-mesh sieve, then add the extractant for flash extraction, and filter through absorbent cotton to obtain the extract; Add 8mL of extractant to the licorice raw material, the temperature of flash extraction is 20°C, and the extraction time is 4min;

[0028] 2) Concentrate the extract A under reduced pressure until the Baume degree is 38 to obtain the concentrate A, then add 4 times the volume ratio of edible alcohol to dilute, settle overnight at 0-10°C, pour out the supernatant, and discard the lower layer Precipitate impurities, and the supernatant is the extract B; the pressure of vacuum concentration is 0.9Pa, and the temperature is 55°C;

[0029] 3) Concentrate the extract B in vacuum until the Baume degree is 29 (the pressure of vacuum concentration is 0.9 Pa, and the tempe...

Embodiment 2

[0031] The extraction method of the aroma components of licorice for tobacco in the present embodiment adopts the following steps:

[0032] 1) Crush the naturally air-dried licorice, pass through a 100-mesh sieve, then add an extractant for flash extraction, and filter through absorbent cotton to obtain the extract; the extractant is mixed with edible alcohol and water, and the volume concentration of edible alcohol is 60% , each gram of licorice raw material corresponds to adding 6mL of extractant, the temperature of flash extraction is 15°C, and the extraction time is 2min;

[0033] 2) Concentrate the extract A under reduced pressure until the Baume degree is 38 to obtain the concentrate A, then add 4 times the volume ratio of edible alcohol to dilute, settle overnight at 0-10°C, pour out the supernatant, and discard the lower layer Precipitate impurities, and the supernatant is the extract B; the pressure of vacuum concentration is 0.9Pa, and the temperature is 55°C;

[00...

Embodiment 3

[0036] The extraction method of the aroma components of licorice for tobacco in the present embodiment adopts the following steps:

[0037] 1) Crush the naturally air-dried licorice, pass through a 100-mesh sieve, then add an extractant for flash extraction, and filter through absorbent cotton to obtain the extract; the extractant is mixed with edible alcohol and water, and the volume concentration of edible alcohol is 75% 10mL of extractant should be added to each gram of licorice raw material, the temperature of flash extraction is 25°C, and the extraction time is 4.5min;

[0038] 2) Concentrate the extract A under reduced pressure until the Baume degree is 38 to obtain the concentrate A, then add 4 times the volume ratio of edible alcohol to dilute, settle overnight at 0-10°C, pour out the supernatant, and discard the lower layer Precipitate impurities, and the supernatant is the extract B; the pressure of vacuum concentration is 0.9Pa, and the temperature is 55°C;

[0039...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap