Wine-making steamer

A technology of a steamer and a lid, which is applied in the field of winemaking, can solve the problems of difficulty in taking out waste materials, inconvenient movement of the steamer, etc., and achieves the effects of simple and easy-to-understand operation, good thermal insulation performance and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

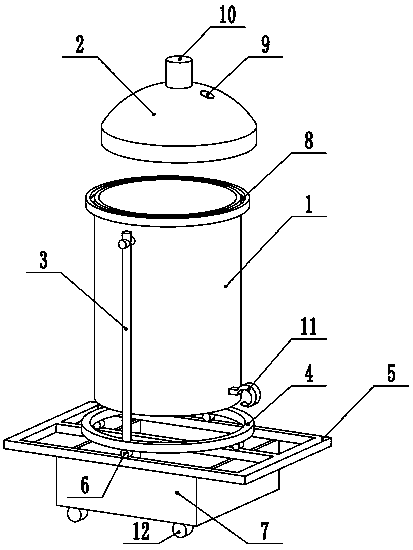

[0014] A wine steamer such as figure 1 As shown, it includes a body 1 and a pot cover 2. The pot cover 2 is a stainless steel conical structure with an air outlet 9 and a distillation outlet 10 above. The outer extension of the upper mouth of the body 1 is provided with a groove 8 for holding water, and the groove 8 is matched with the side of the pot cover 2, and the side of the pot cover 2 is not over the water surface in the groove 8 , Use the water seal method to prevent the leakage of wine gas, and the sealing effect is good. The body 0 is rotatably fixed on the columns 3 on both sides of the body, the wall of the body 1 is a double-layer structure, the interior is vacuum, and a hook 11 is provided on the outside of one side, which can be realized by pulling the hook 11 The main body 1 rotates in the two uprights 3 so as to dump the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com