Automatic control hydraulic pump testing system and method

A testing system and hydraulic system technology, which is applied in fluid pressure actuation system testing, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of low testing frequency, low degree of automatic operation, and high labor intensity of testers, and achieve High degree of automation, simple structure, solve the effect of low degree of automation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

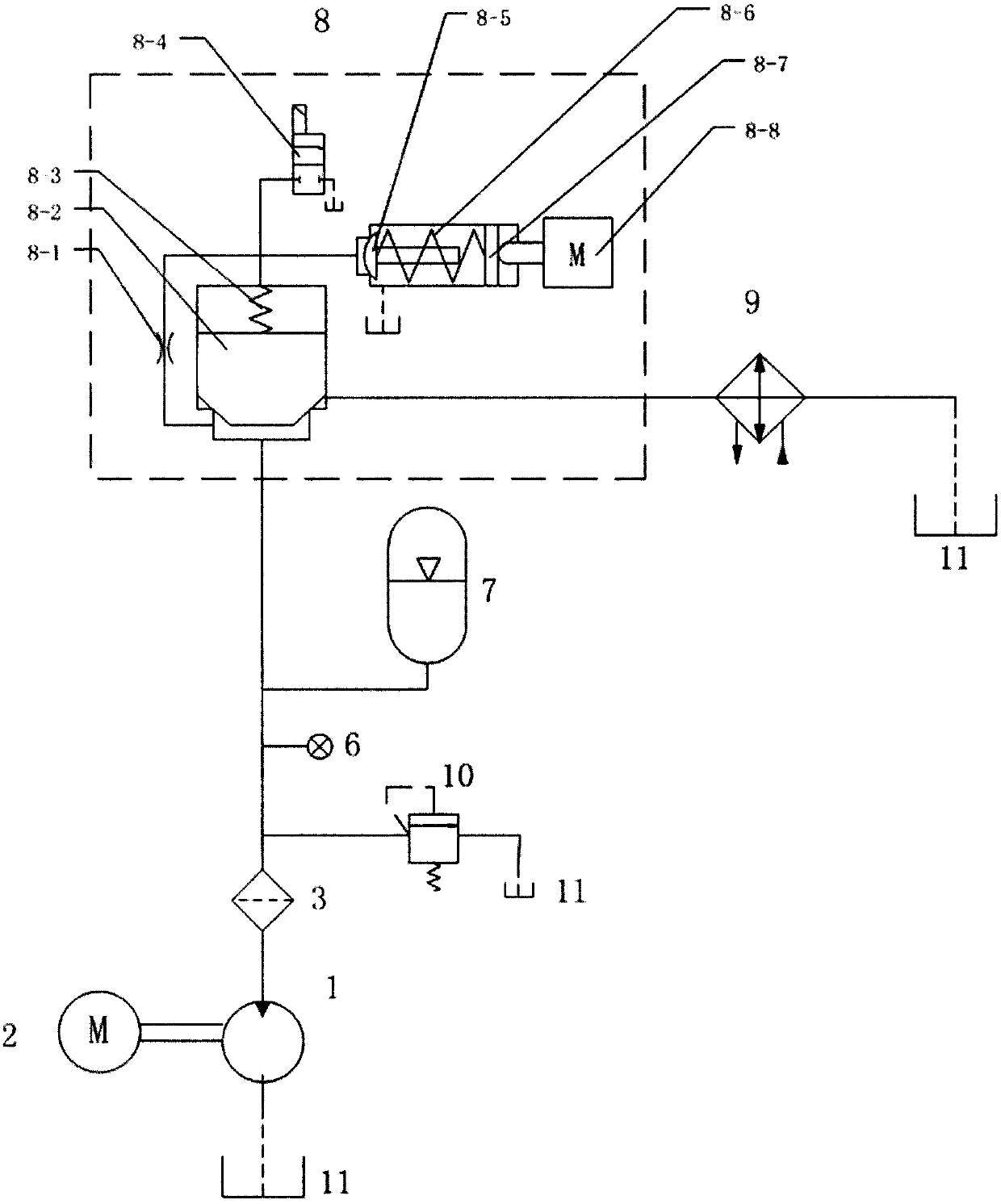

[0039] figure 2 It is the principle diagram of the tested hydraulic pump testing system of the present invention, which mainly includes: 1-tested hydraulic pump; 2-drive motor; 3-filter; 6-pressure sensor; 7-accumulator; 8-digital regulator Pressure valve; 9-cooler; 10-safety valve; 11-liquid tank.

[0040] The drive motor 2 drives the tested hydraulic pump 1 to absorb liquid from the liquid tank 11, and the oil returns to the liquid tank after passing through the filter 3 digital pressure regulating valve 8 and the cooler 9; Pressure sensor 6, accumulator 7 and safety valve 10.

[0041] Among them, the filter filters the oil, the accumulator stabilizes the outlet pressure and flow pulsation of the hydraulic pump, the pressure sensor feeds back the system pressure, cooperates with the upper computer software to realize the automatic control of the system, the cooler cools the oil, and the safety valve plays a role in the system. overload protection.

Embodiment 2

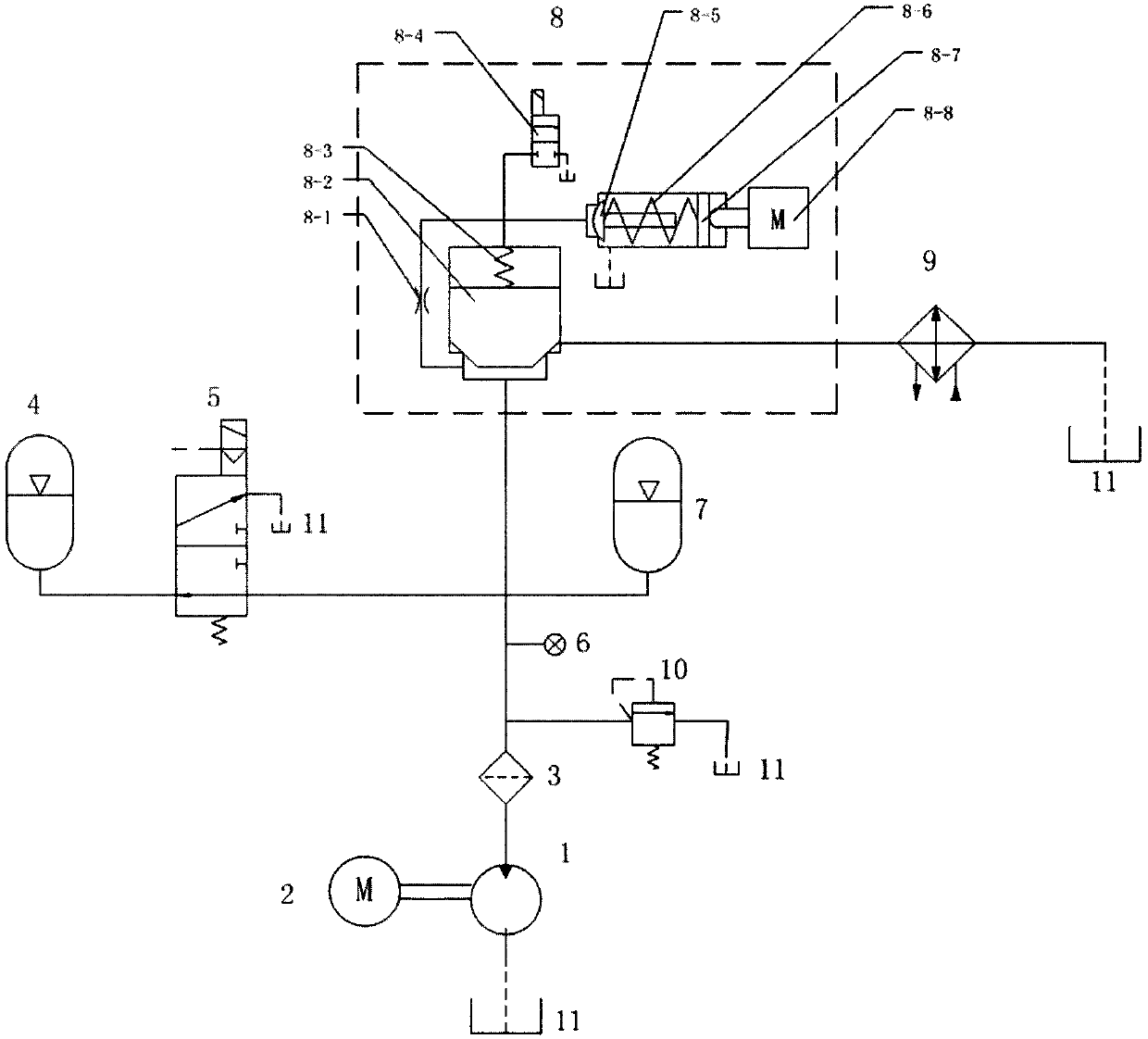

[0043] Such as image 3 As shown, an accumulator group is set at the outlet of the tested hydraulic pump 1, and the accumulator group includes an accumulator 7 and a second accumulator 4 connected in parallel, wherein a pilot type electromagnetic converter is connected in series before the accumulator 4 Directional valve 5; wherein the second accumulator 4 is an accumulator with low restart pressure, and accumulator 7 is an accumulator with high restart pressure

[0044] The tested hydraulic pump test system is realized by the following methods:

[0045] When the hydraulic system starts, the driving motor 2 drives the hydraulic pump 1 to suck liquid from the liquid tank 11. At this time, the software of the host computer sends a control signal to the solenoid pilot valve 8-4 of the digital pressure regulating valve, and the digital pressure regulating valve The spool of the electromagnetic pilot valve 8-4 changes direction, and the oil enters the front chamber of the main spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com