Oil seal durability test equipment

A durability test and oil seal technology, which is applied in machine sealing ring testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as high cost, complex structure, and inability to accurately predict durability, and achieve guarantee The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

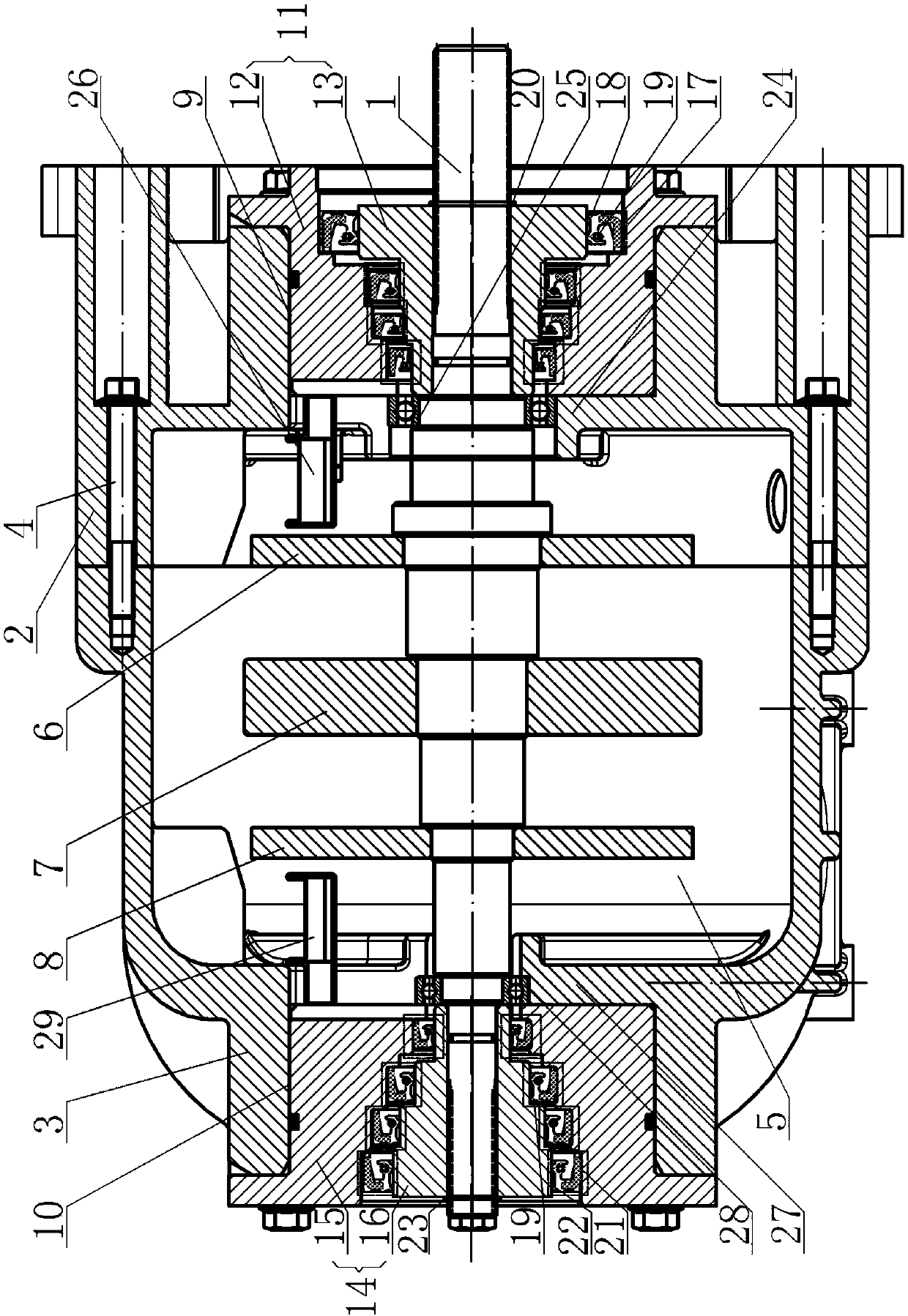

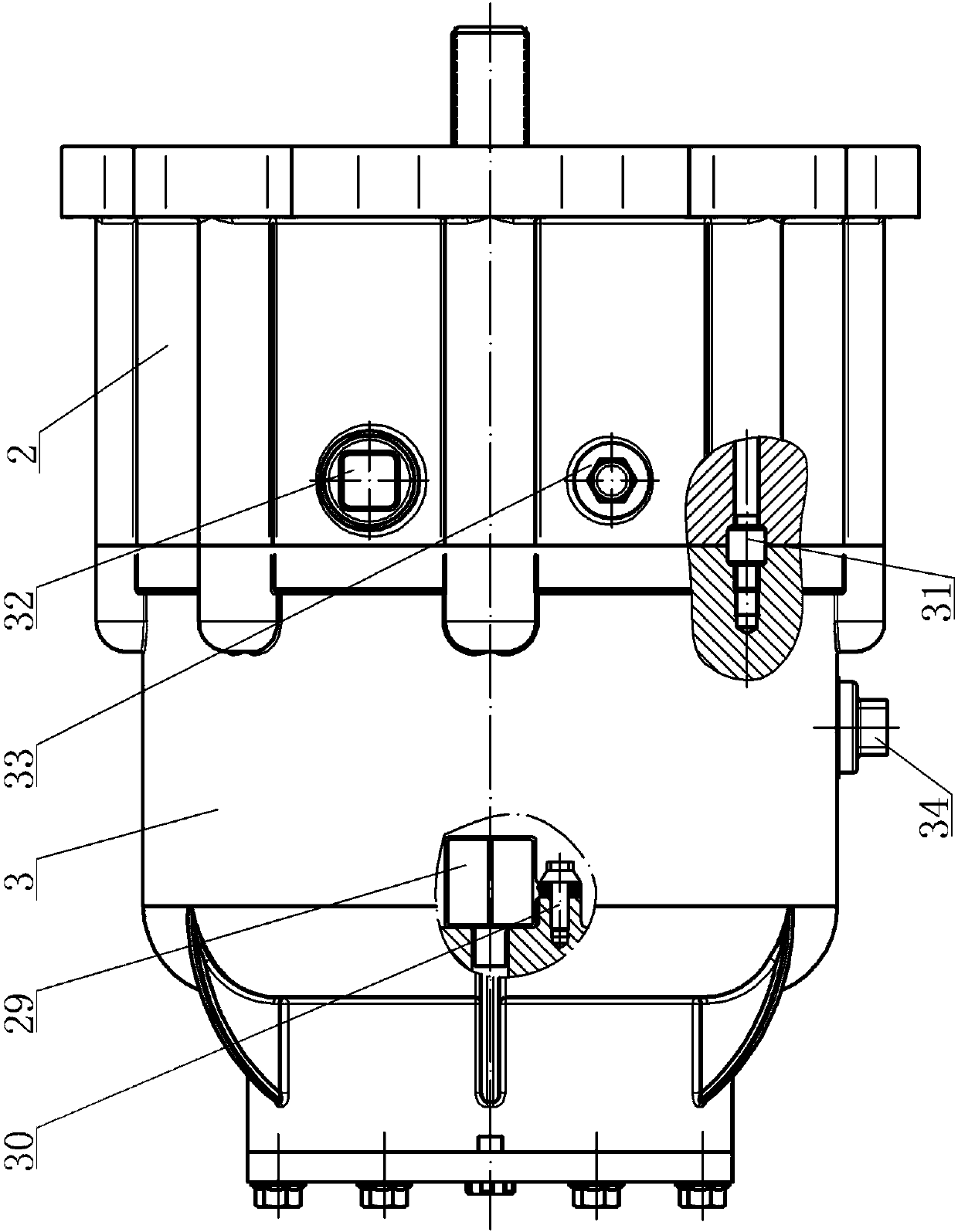

[0018] A kind of oil seal durability test equipment, see figure 1 , figure 2 : It includes a transmission shaft 1, the front end and the rear end of the transmission shaft 1 are respectively set with a front housing 2 and a rear housing 3 through bearing positioning, and the opposite annular end faces of the front housing 2 and the rear housing 3 pass through the box positioning flange 4. Tightly connected, the front housing 2 and the rear housing 3 are combined to form a central cavity 5, and the position of the transmission shaft 1 corresponding to the central cavity 5 is arranged at intervals with a front oil throwing plate 6, an inertia plate 7, and a rear oil throwing plate. Disc 8, the center of the front end of the front housing 2 is indented to form a positioning cavity 9 for the front quick change sleeve, the center of the rear end of the rear housing 3 is indented to form a positioning cavity 10 for the rear quick change sleeve, and the front quick change sleeve 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com