Pin feeding and assembling station of automatic assembling machine for charging plugs

An automatic assembly machine and assembly station technology, applied in the assembly/disassembly of contacts, metal processing, manufacturing tools, etc., can solve the problem of metal pins damaging the outer surface of the insulating half-shell, and achieve good assembly effect and avoid damage. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

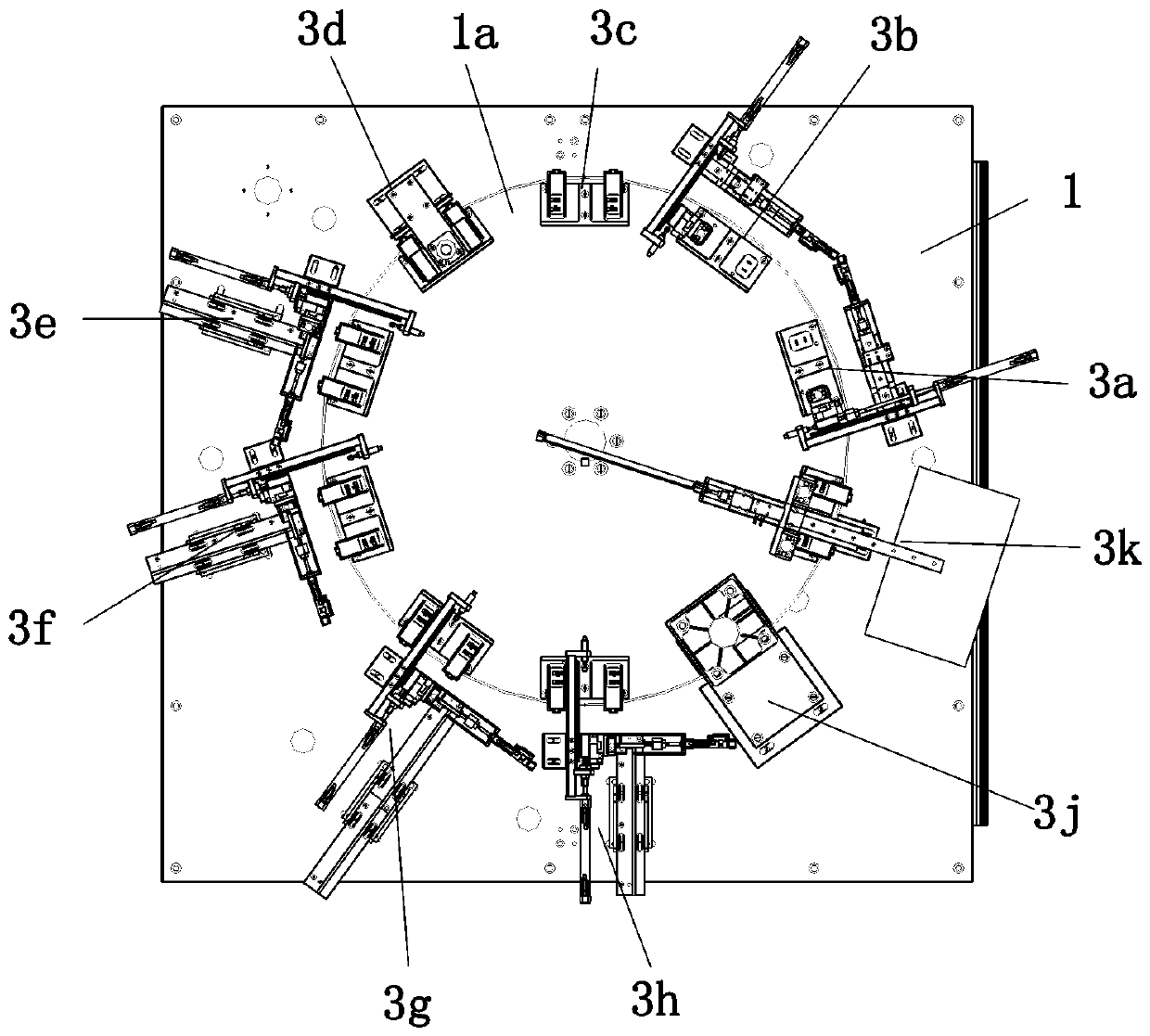

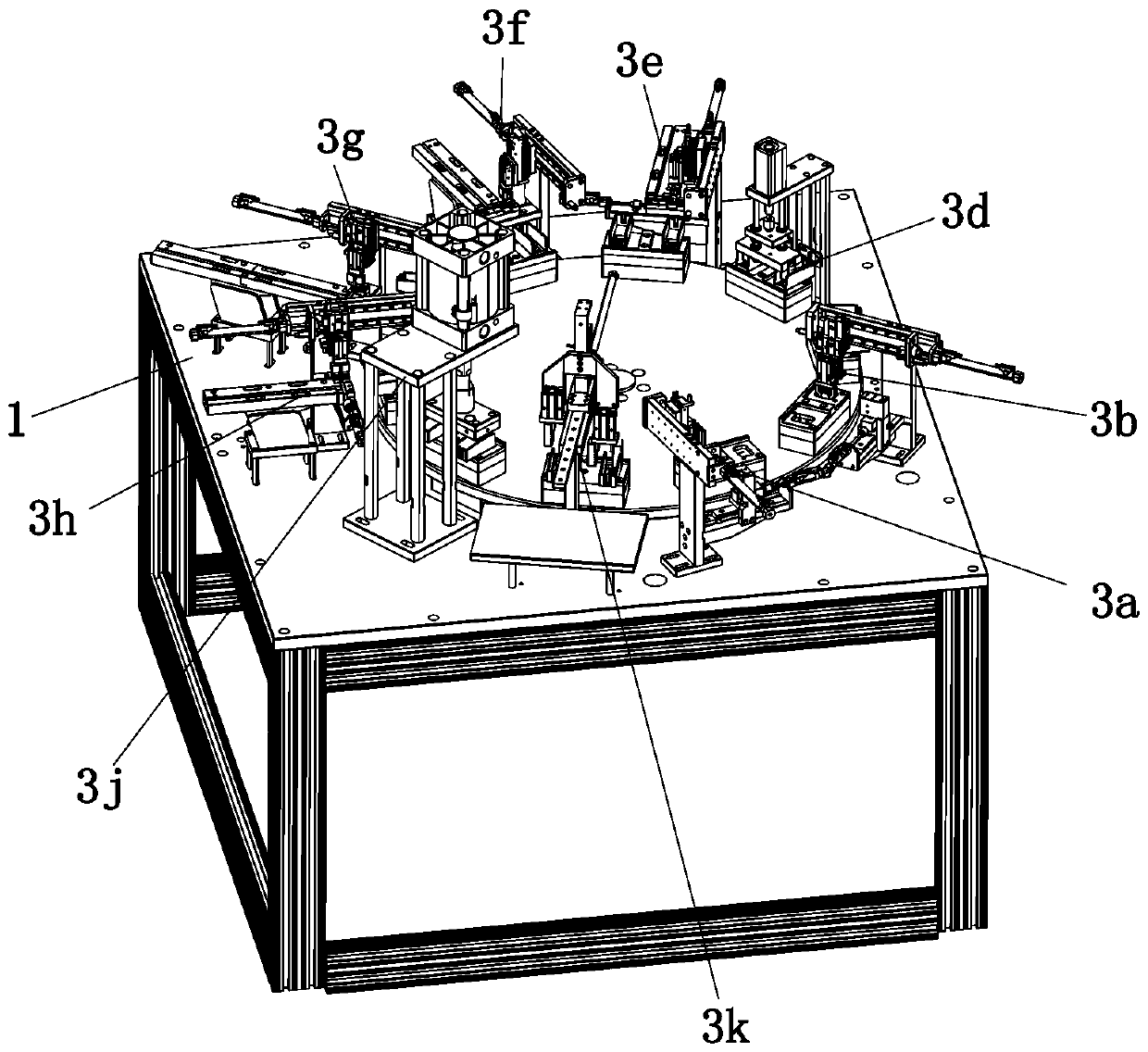

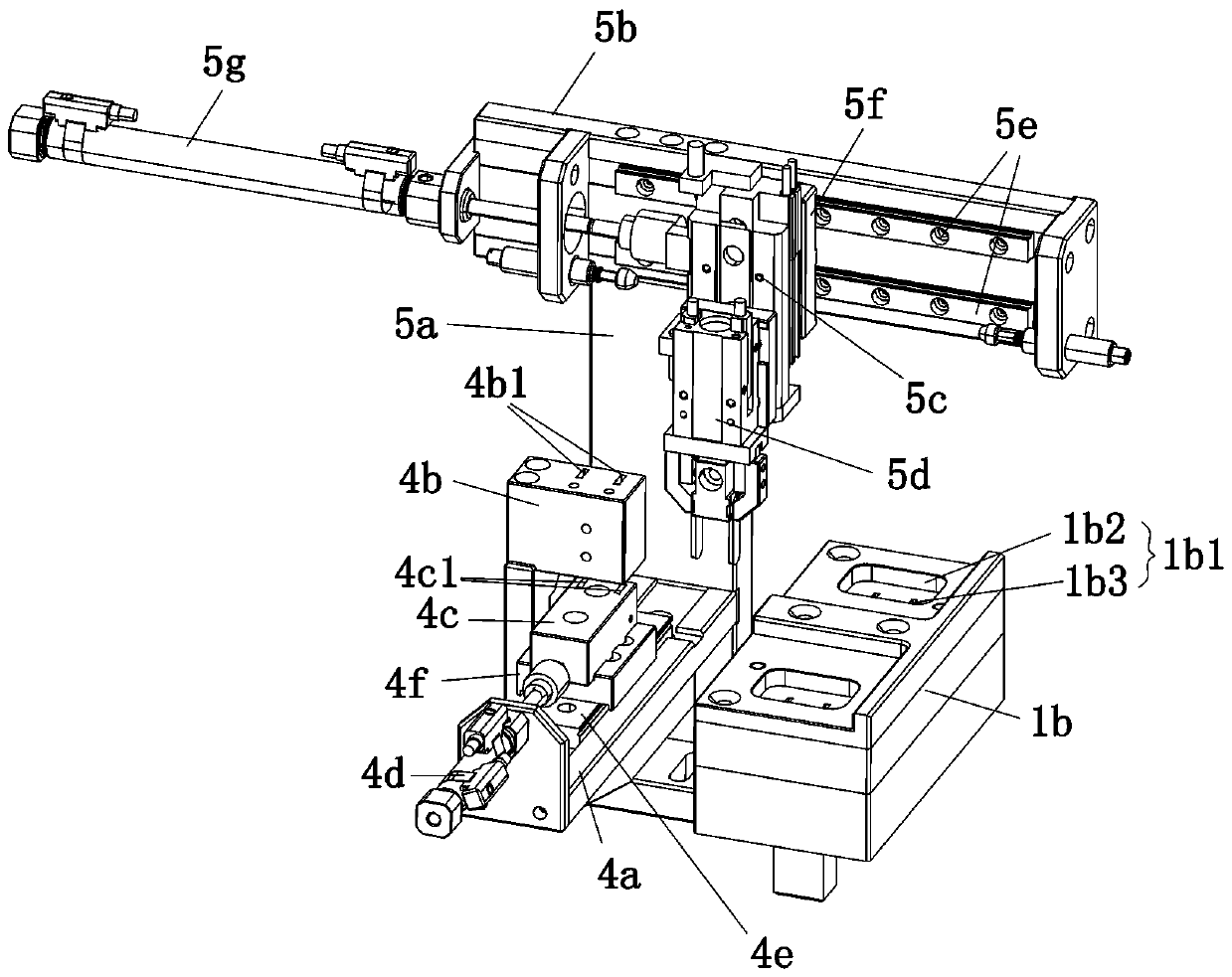

[0031] refer to Figure 1 to Figure 15The shown automatic assembly machine for a charging plug includes a workbench 1, on which a turntable 1a driven by a stepping motor to realize a step-by-step rotary motion is arranged, and a number of positioning jigs 1b are distributed on the turntable 1a. There are two positioning slots 1b1 inside the jig 1b. The design of the two positioning slots 1b1 enables the present invention to assemble two charging plugs at a time. The workbench 1 is located around the turntable 1a and is arranged sequentially along the rotation direction of the turntable 1a. The first group of pin feeding and assembly station 3a, the second group of pin feeding and assembly station 3b, the double insulating half shell feeding station 3c, the insulating half shell pressing down station 3d, and a group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com