High-efficiency and energy-saving series-pole and series-winding ultra-low speed direct-drive motor

A high-efficiency, energy-saving, direct-drive motor technology, applied to the shape/style/structure of winding conductors, windings, electrical components, etc., can solve problems such as large loss rate of starting energy consumption, high starting torque, and difficulty in volume transportation and installation. Achieve obvious energy saving effect, reduce driving loss, and small outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

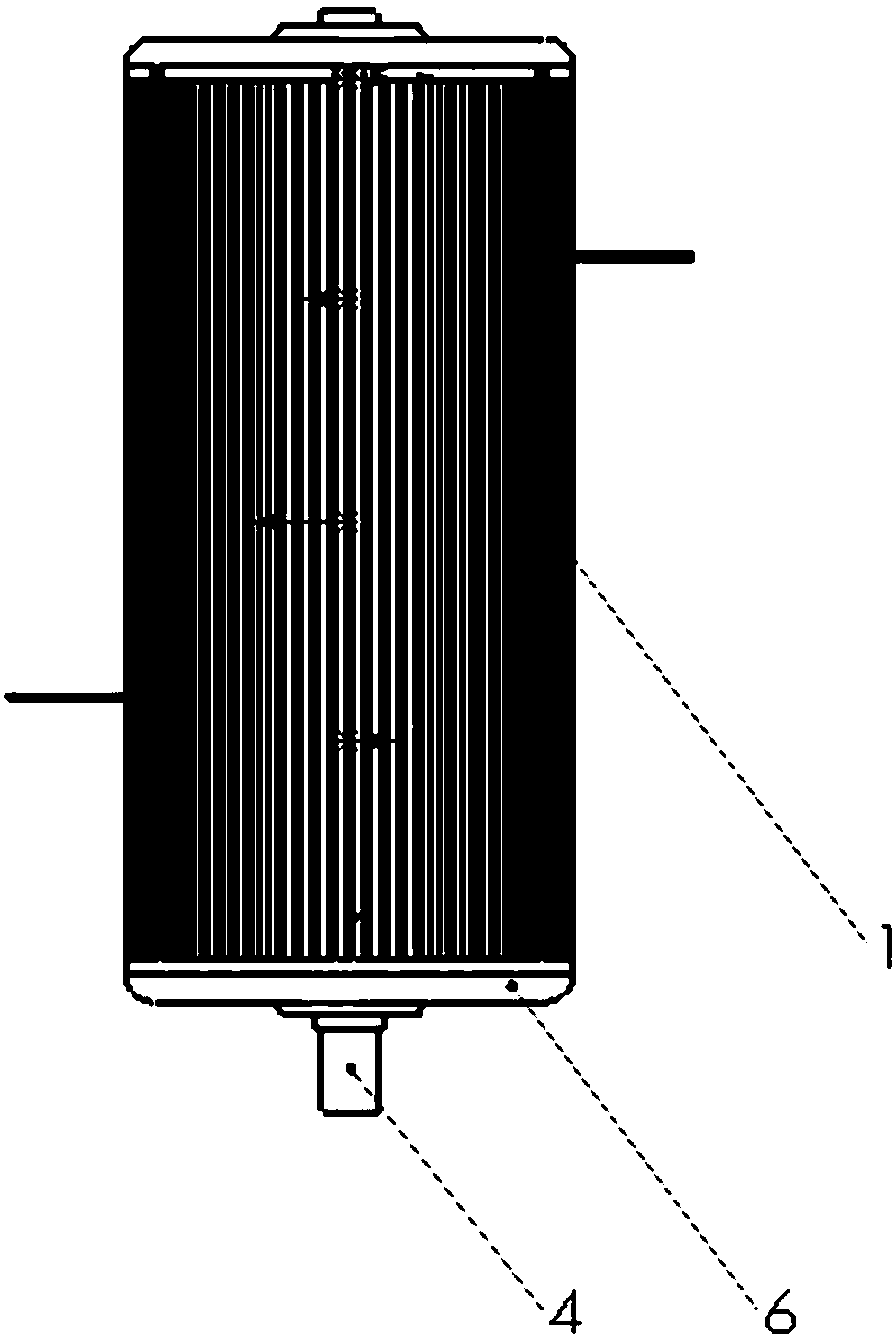

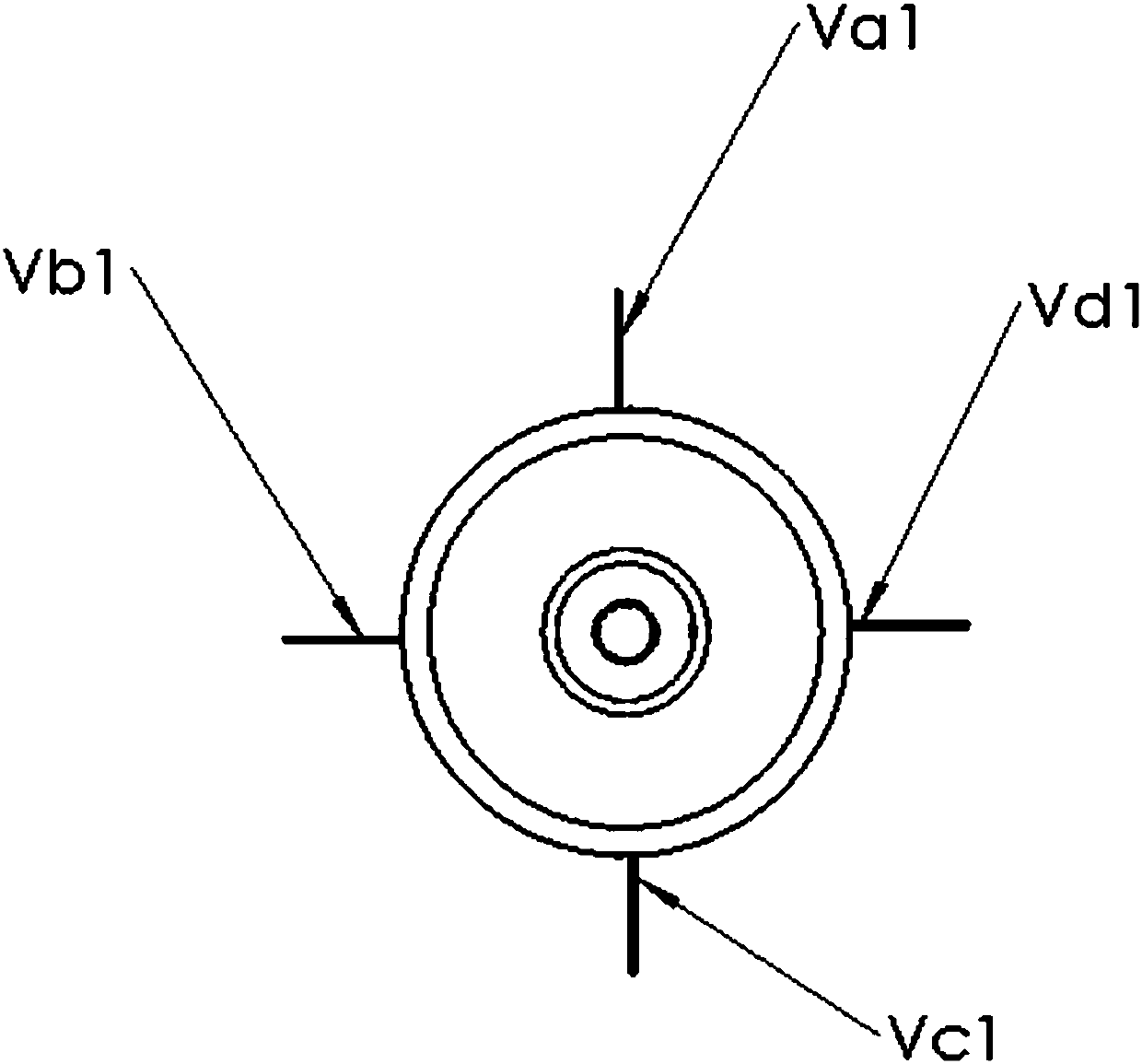

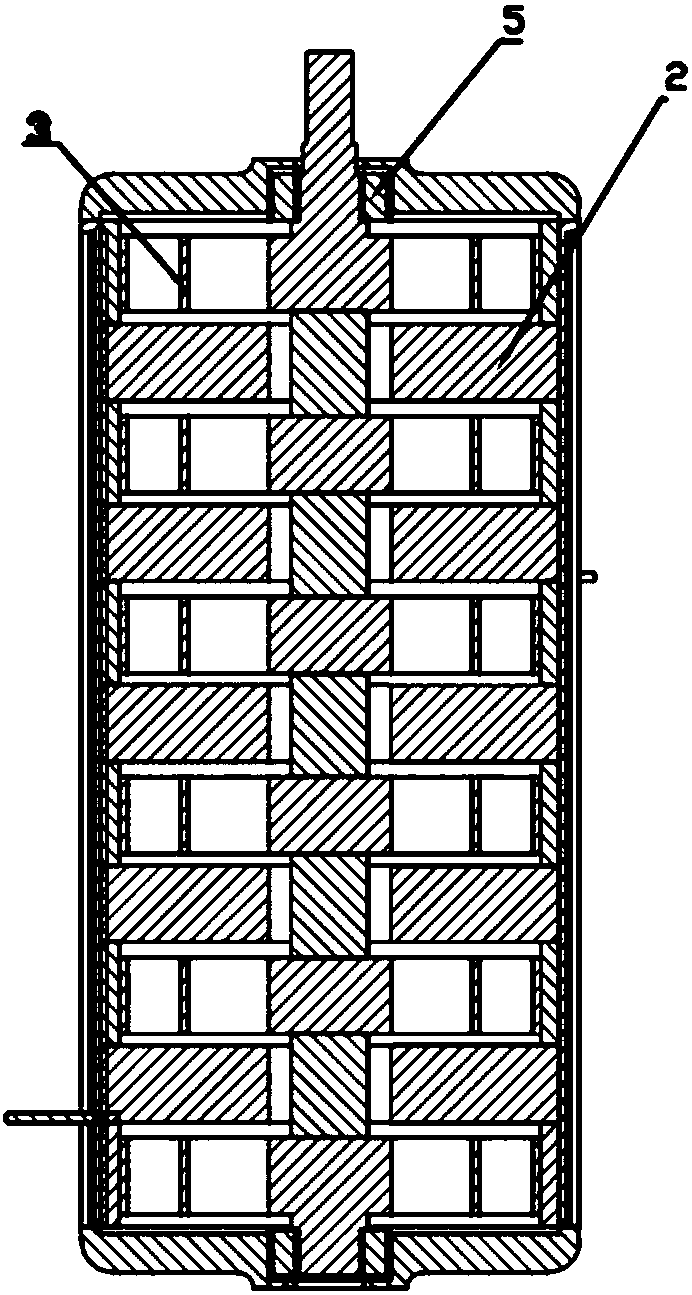

[0034] Such as Figure 1-8 As shown, a high-efficiency energy-saving series pole series group ultra-low-speed direct drive motor includes a motor housing 1, a stator 2, a rotor 3, a rotor shaft 4, a bearing 5 and a motor end cover 6, and the two ends of the motor housing 1 are open A motor end cover 6 is provided at the center, and the two ends of the rotor shaft 4 are respectively arranged at the axial center of the motor end cover 6 at both ends of the motor casing 1 through bearings 5. The inner side of the motor casing 1 is sequentially arranged along its axial direction A plurality of stators 2 or rotors 3, the rotor shaft 4 is sequentially provided with a plurality of rotors 3 or stators 2 matched with the stators 2 or rotors 3 on the motor housing 1 along its axial direction; from one end of the rotor shaft 4 to At the other end, the wiring taps U2, V2, W2 of the coils of the stator 2 are respectively connected in series or in parallel with the wiring taps U1, V1, W1 of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap