Polymerization Process

A polymerization method and polymer technology, applied in the field of polymerization, can solve the problems of increasing the melt index and reducing the density of the polymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

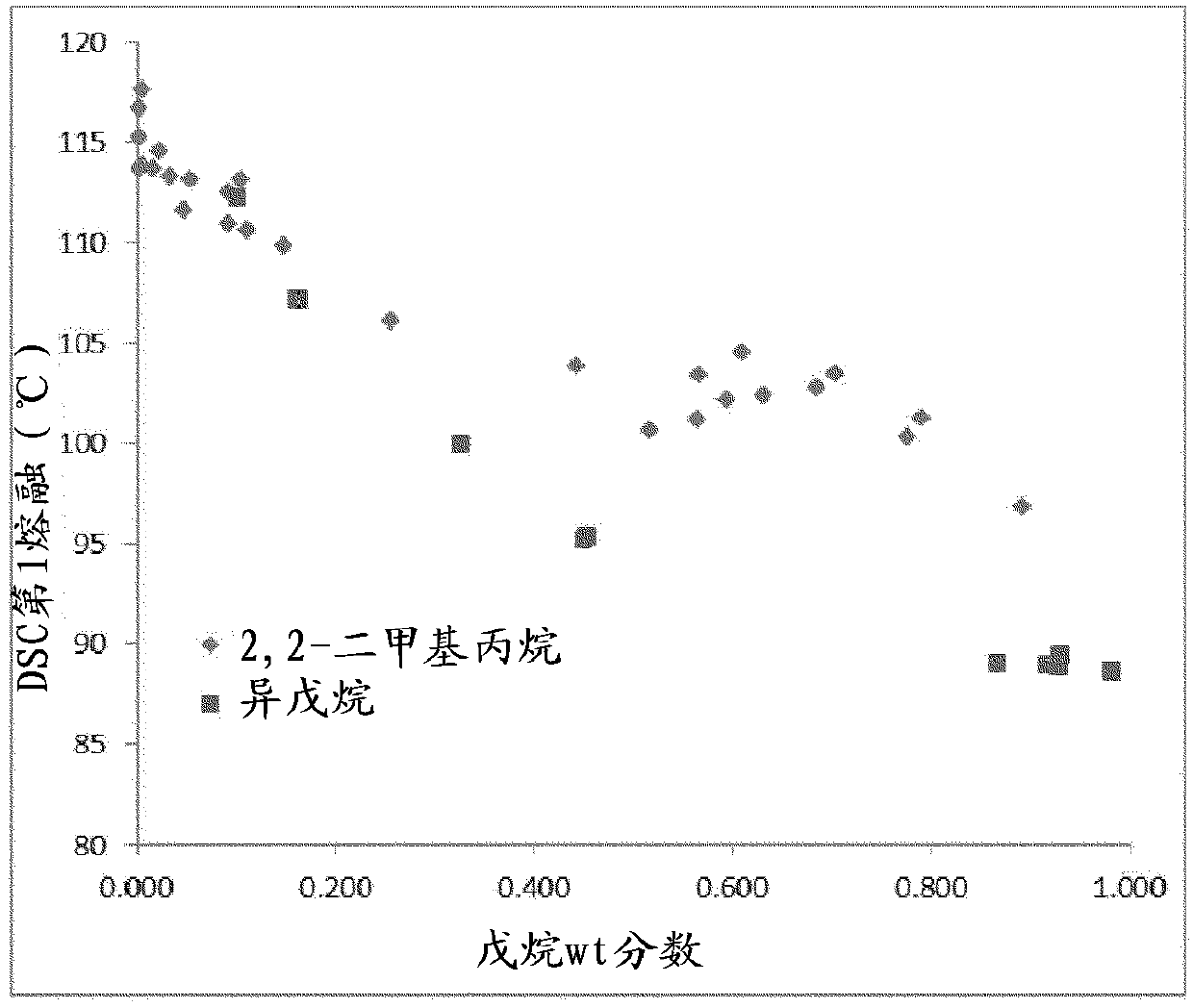

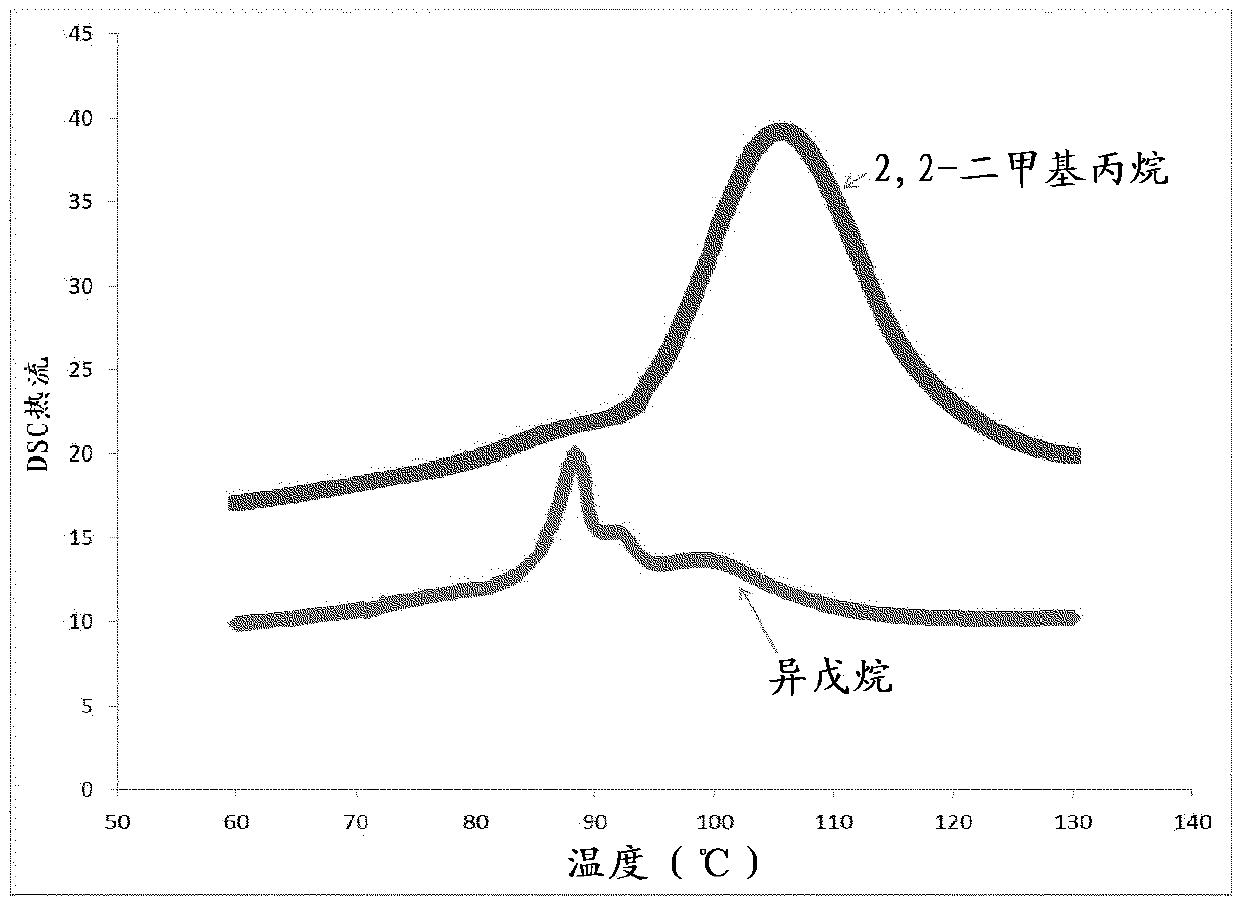

[0086] Differential Scanning Calorimetry (DSC) tests were performed on PE particles in contact with isopentane or 2,2-dimethylpropane.

[0087] For each polymer evaluated, only the first melt DSC was used, as this was believed to be more representative of the polymer as it existed in the reactor compared to the more conventional second melt DSC curve. The second melting DSC curve can differ significantly from the first melting DSC curve, typically showing a lower peak melting temperature and a sharper melting peak.

[0088] In the data in Table 1 below, a DSC curve was generated using a ramp rate of 10°C / min. The DSC device is TAInstruments Q200. PE particles are hexene-ethylene copolymers with an initial MI of 1.0 dg / min (ASTM D-1238) (190°C / 2.16kg) 2.1 , MI of 34dg / min (ASTM D-1238) (190℃ / 21.6) 21 and a density of 0.920g / cc (ASTM D-4703). To reduce experimental scatter, the granules were then sieved so that the granules were retained on 35 mesh for DSC testing with isope...

Embodiment 2

[0095] This example compares DSC first melt data for samples with similar amounts of ICA. These data are presented as two data points included in Table 1. Raw material, equipment and process are all identical with embodiment 1. 2,2-Dimethylpropane corresponds to a 0.444 wt fraction, which represents a significantly higher melting point and MIT compared to the 0.451 wt fraction of isopentane, as figure 2 shown.

Embodiment 3

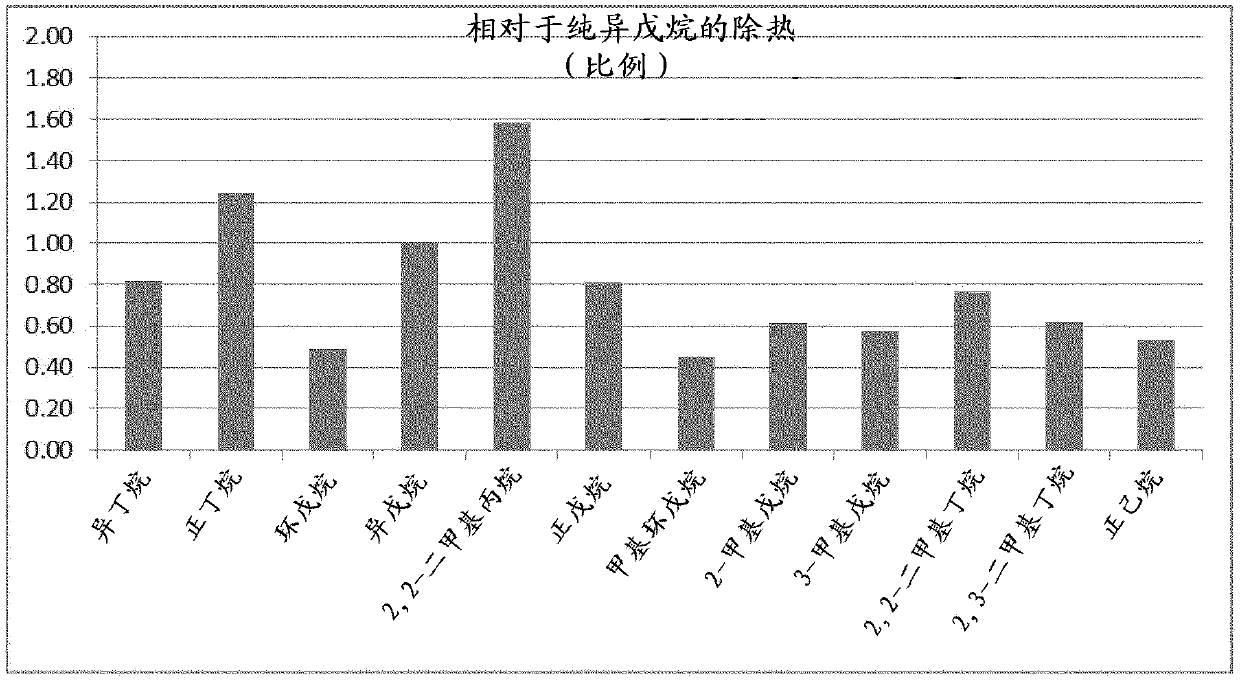

[0097] These examples simulate reactor operation using various ICAs. The simulation was performed using the method shown in column 62, line 48 through column 69, line 51 of U.S. Patent No. 7,683,140. These examples use raw materials of the same physical properties as the aforementioned patents. These examples also use the same exemplary calculations used in U.S. Patent No. 7,683,140 (see Table 3 at Col. 69). These examples demonstrate ΔMIT. Table 2 shows the full set of solubility parameters used in these examples.

[0098] Table 2: Solubility parameters ((cal / cm 3 ) 1 / 2 )

[0099] n-butane

7.062

6.853

n-pentane

7.055

6.771

2,2-Dimethylbutane

6.382

1-Hexene

7.352

7.95

[0100]Once the recycle gas concentration is fixed, the heat removal capacity of the recycle gas loop is usually calculated based on achieving a target value for ΔMIT. For illustrative purposes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com