Manufacturing method of multiposition microwave reactor with reflection cavity

The technology of a microwave reactor and a reflective cavity is applied in the field of scientific experiments, which can solve the problems of reducing the microwave absorption rate and the large difference in microwave absorption, and achieves the effects of easy temperature control, increased application value, and improved microwave utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

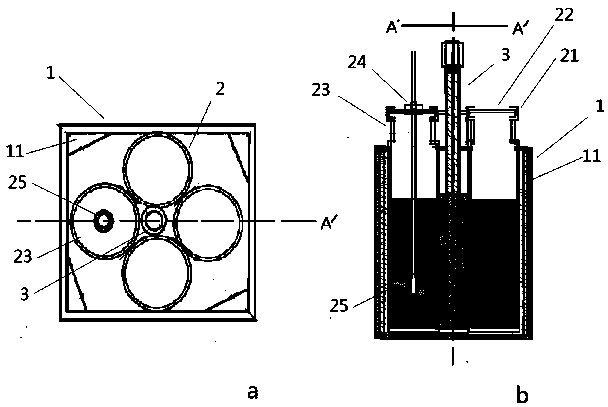

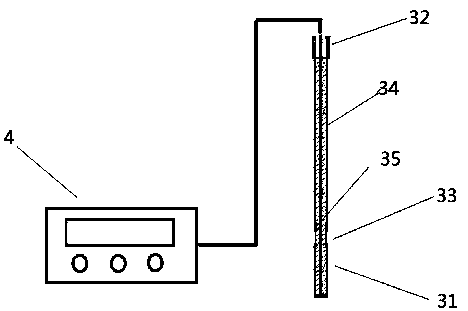

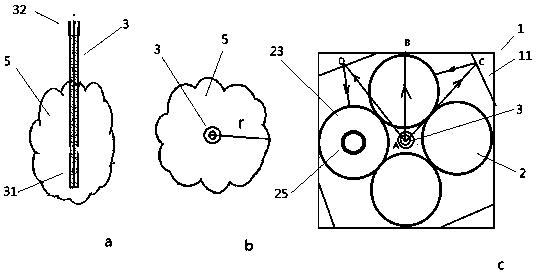

[0020] Such as figure 1 As shown, a multi-position microwave reactor with a reflective cavity includes a reflective cavity, a reactor assembly and a microwave radiator assembly. It is characterized in that the reflective cavity is made of microwave reflective material and has a square tubular cross section Housing 1, the four corners of the tubular housing 1 are provided with microwave reflectors 11; the reactor assembly includes four tubular reactors 2 arranged side by side with a square cross-section, the diagonal of the square cross-section and the The cross-section diagonals of the reflecting cavity are vertically arranged in the tubular housing 1; the microwave radiator assembly includes a microwave radiation head 3 and a microwave source 4, and the radiation head 3 is a rod-shaped slot antenna radiator with a radiation end 31 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com