Wool Top Microwave Dryer and Wool Top Microwave Drying Method

A microwave drying and drying machine technology, applied in the textile field, can solve problems such as condensation on the surface of wool tops, achieve the effects of enhancing drying capacity, prolonging microwave drying time, and improving microwave utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

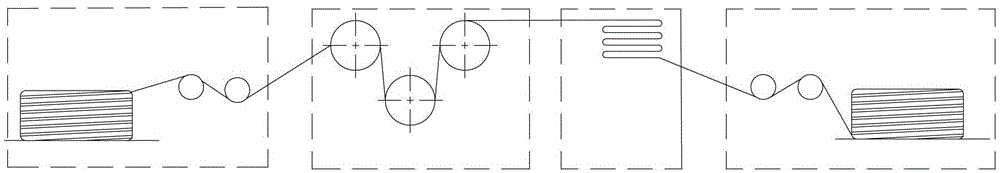

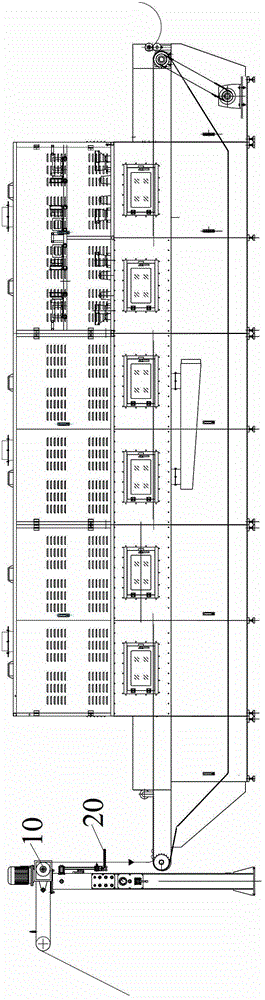

[0020] see figure 1 and figure 2 , according to the wool top microwave dryer of the present invention, comprising a microwave drying section, the transmission device is configured such that the wool top forms a multi-layer drying layer in the microwave drying section, the multi-layer drying layers are connected end to end in sequence, and the speed of the transmission device is less than The speed of other processes. In order to give full play to the efficiency of microwave, improve microwave utilization rate and drying quality, and reduce dew condensation on the surface of wool top, in the operation of microwave wool top production line, the method of segmented variable speed drying process is adopted, and the speed of drying layer conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com