Polypropylene coated paper container capable of being used in microwaves and processing technology thereof

A processing technology and technology of coated paper, applied in the field of paper containers, can solve the problems of paper container stiffness and barrier performance decline, low melting point of PE coating layer, melting of PE coating layer, etc., to improve production efficiency and stabilize quality The effect of high sex and strong flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-5 The application is described in further detail.

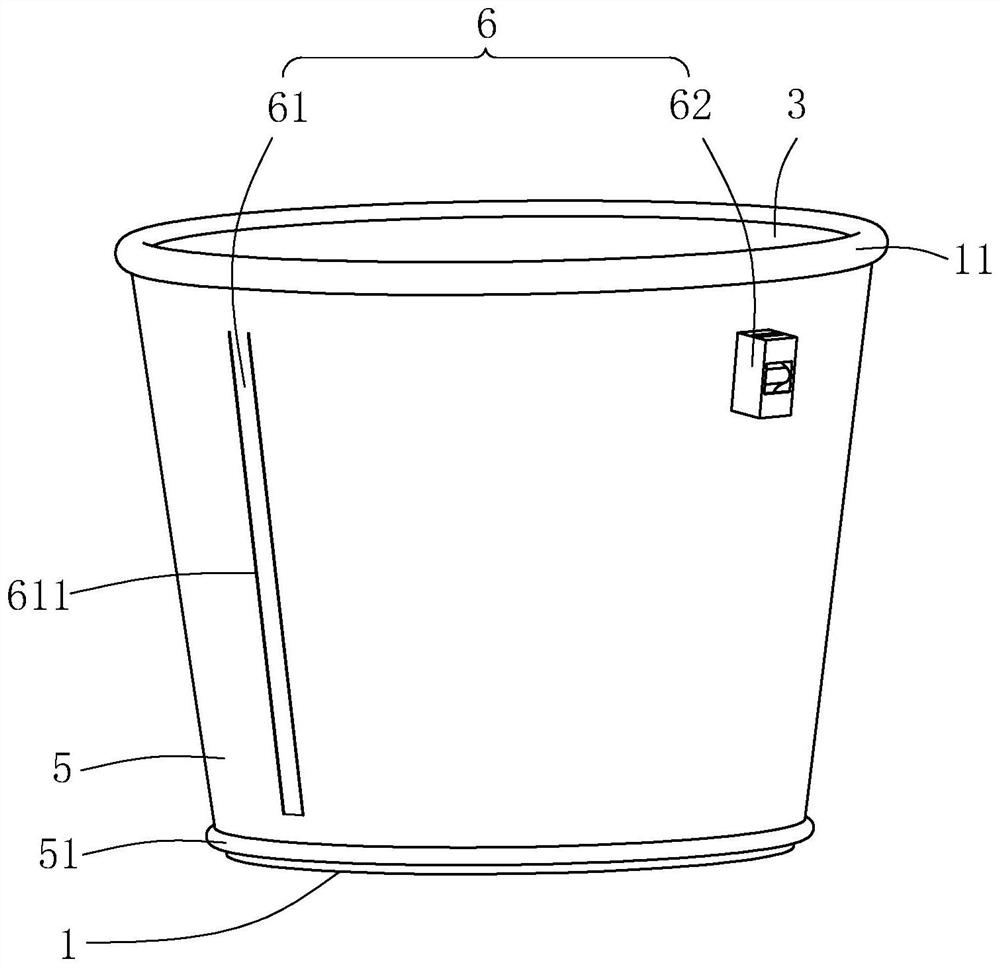

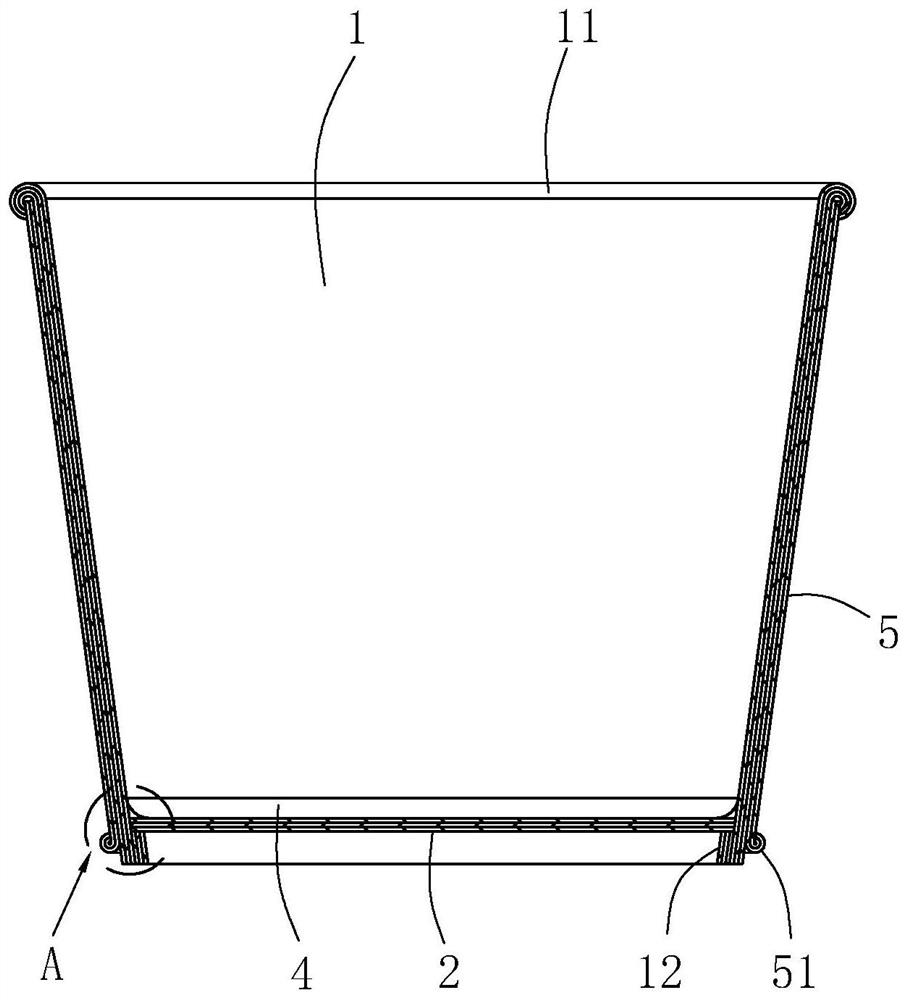

[0045] The embodiment of the present application discloses a microwaveable PP coated paper container. refer to figure 1 and figure 2 , Microwaveable PP coated paper container includes container wall 1, container bottom 2, printing layer 5, PP coating layer 3 and cover assembly 6, container bottom 2 is connected to the lower side of container wall 1, and the upper end of container wall 1 forms the container Opening, the printing layer 5 is set outside the container wall 1 , and the cover assembly 6 is set on the printing layer 5 .

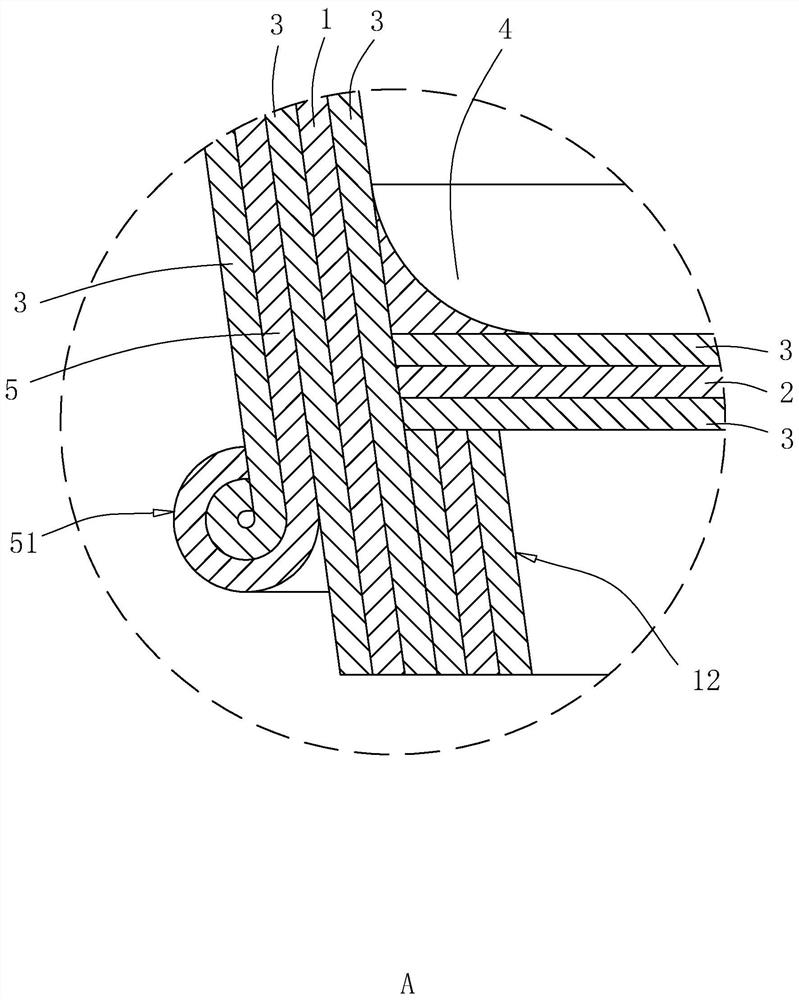

[0046] refer to figure 2 and image 3 , the container wall 1 and the container bottom 2 are sprayed with a PP coating layer 3 on the inner wall and the outer wall, wherein the container wall 1 is formed by bending and bonding fan-shaped double-sided PP coating paper sheets, and the adhesive used for bonding It is the PP coating that melts after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com