3D printing equipment for metamaterial preparation

A 3D printing and metamaterial technology, applied in metal processing equipment, 3D object support structure, additive manufacturing, etc., can solve the problems such as preparation methods restricting the development and application of metamaterials, cumbersome preparation process, etc., to ensure the quality and applicability of printed products. A wide range of effects to ensure printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

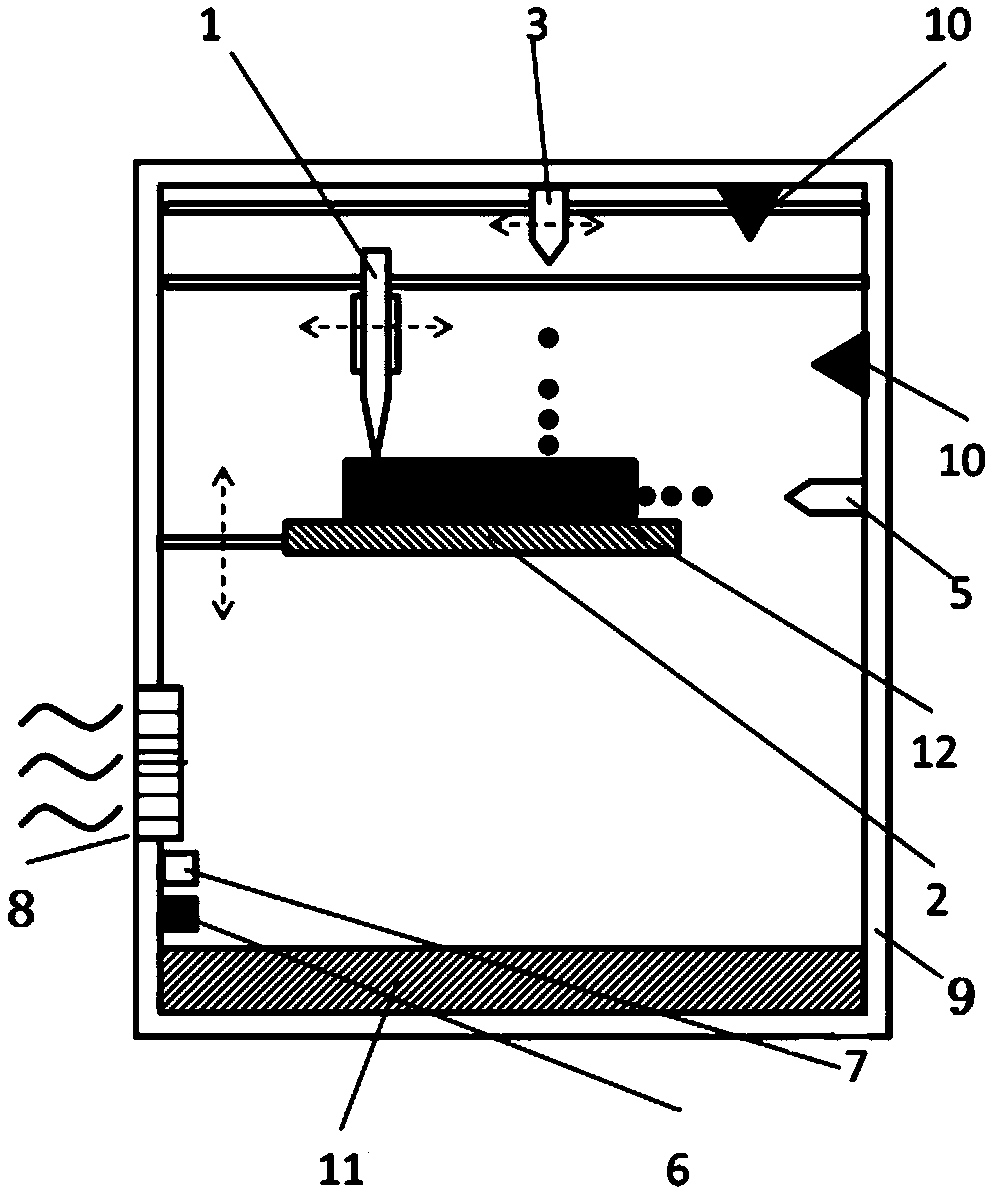

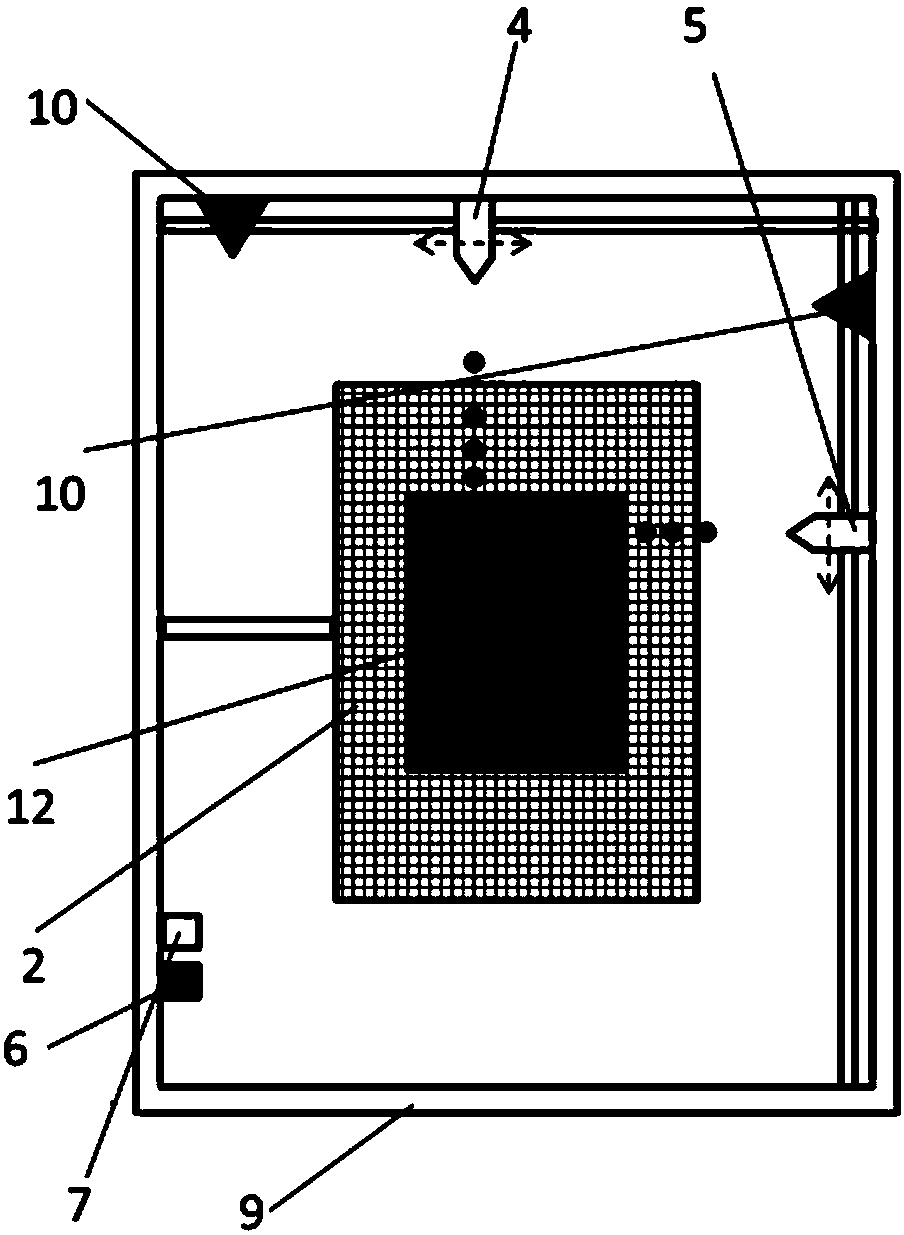

[0057] A 40*40cm metal box is used, and the size of the bottom plate is 25*25cm.

[0058] The substrate deposition system uses the fusion deposition method, adopts a single extrusion needle with a heating jacket, the diameter is 0.5 mm, the deposition temperature is 180 °C, and the deposition material is ABS resin. A single inkjet nozzle with a diameter of 0.3 mm is used, which is arranged in parallel with the extrusion needle, and the two move independently. Silver nanoparticles (average size 100 nm) ink was used. Both the extrusion needle and the inkjet nozzle are driven by two motors, and each moves in the XY plane, while the bottom plate is driven by a single motor, and moves in the Z direction. The temperature of the cabinet is controlled at 50°C and the relative humidity is less than 5%.

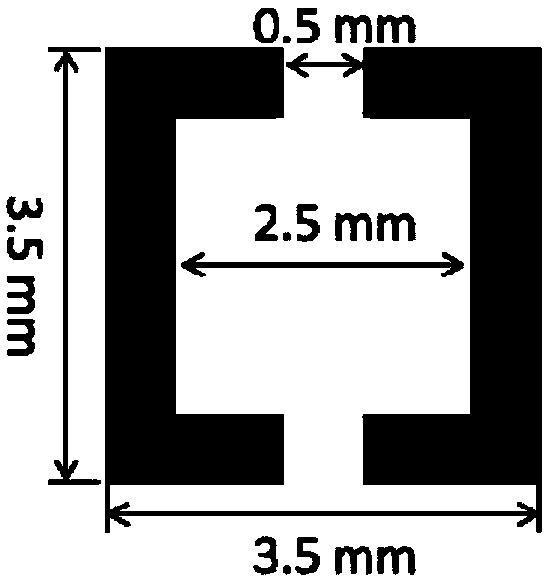

[0059] image 3 The shape shown is a conductive structural unit, the thickness of the unit is 0.2 mm, and the spacing is 1 mm. A two-dimensional metamaterial with a size of 15*15 cm...

Embodiment 2

[0061] It adopts a 40*40cm metal box, and the size of the bottom plate is 25*25cm.

[0062] The substrate deposition system uses the UV curing deposition method, using butyl acrylate as the monomer, the UV initiator is 1173, the nozzle diameter is 0.5 mm, and it moves independently in the XY plane. Use three orthogonal inkjet nozzles with a diameter of 0.3 mm, two of which are located in the XY plane and move independently along the X-axis and Y-axis directions, and the other is located in the positive direction of the Z-axis parallel to the extrusion needle. Independent movement in the XY plane, the bottom plate is driven by a single motor and moves along the Z direction. Silver nanoparticles (average size 100 nm) ink was used. The temperature of the cabinet is controlled at 40°C and the relative humidity is less than 5%.

[0063] Based on a 5*5*2 mm cuboid, with image 3 The shape shown is a conductive structure, which constitutes the structural unit of the metamaterial, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com