A kind of manufacturing method of lacquered wood-plastic composite floor

A technology of wood-plastic composite and manufacturing method, which is applied in the direction of floor covering, chemical instruments and methods, floors, etc., and can solve the problems of energy waste, waste of time, and low efficiency of board manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

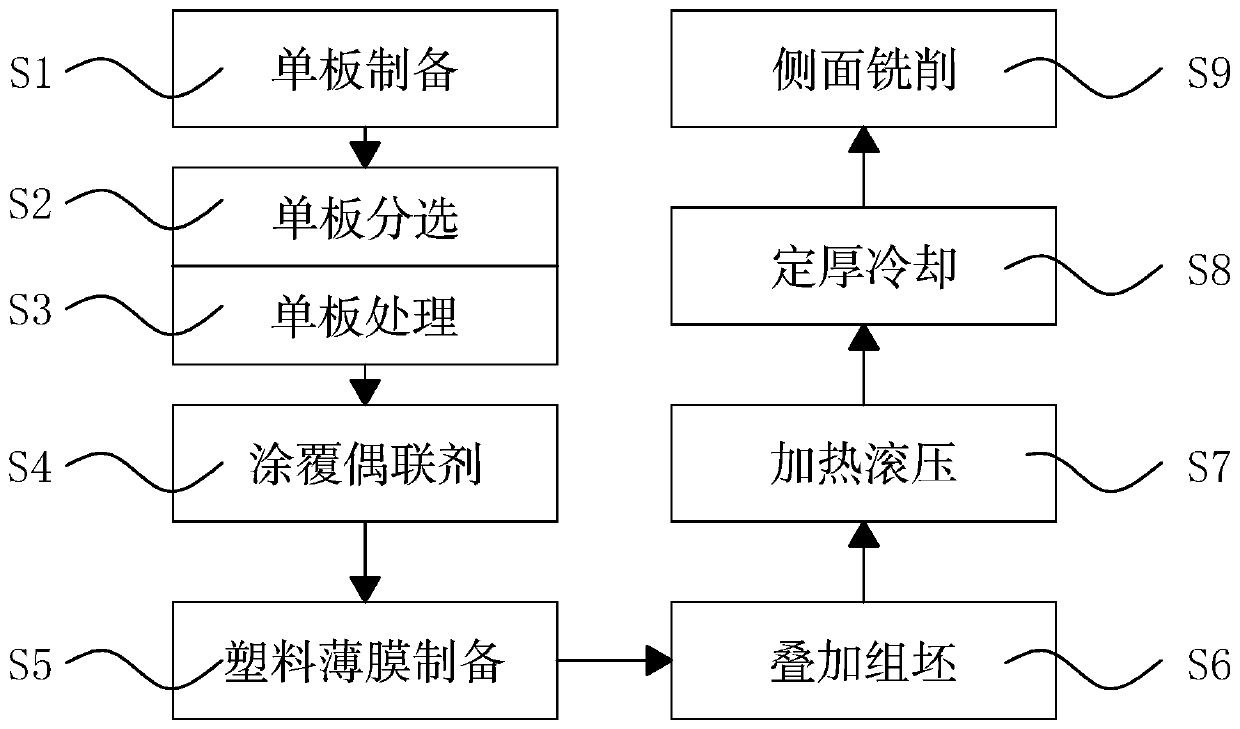

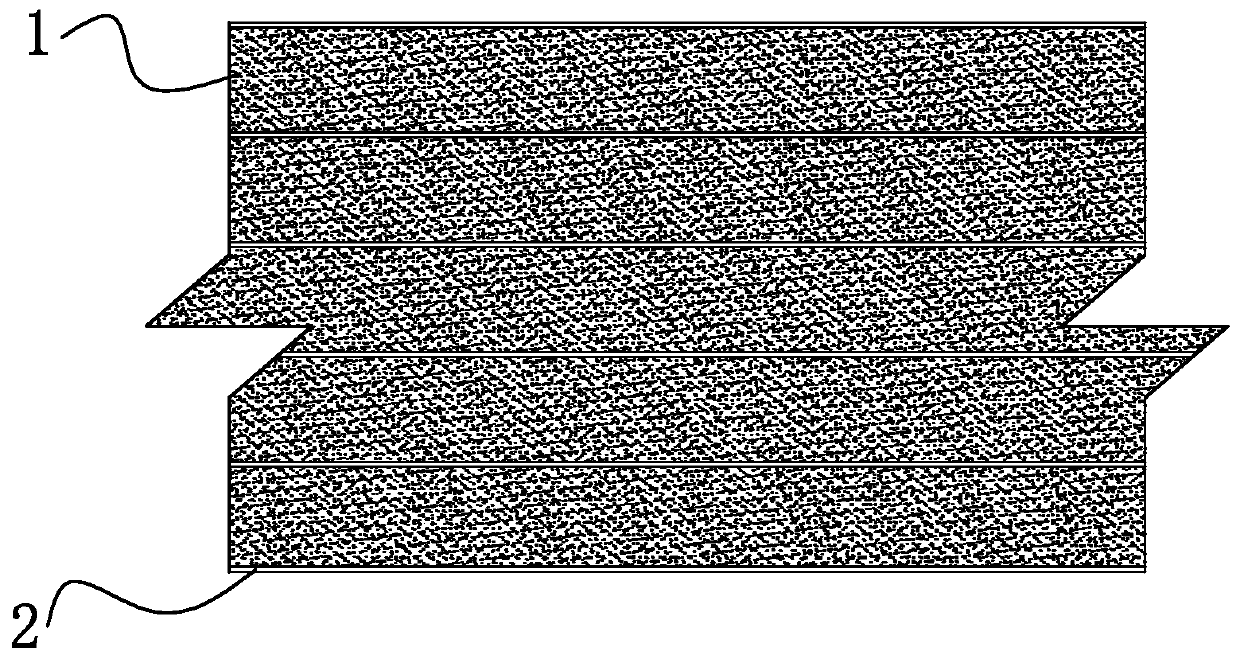

[0019] Specific Embodiment 1: Combining figure 1 Description of this embodiment, a method for manufacturing lacquered wood-plastic composite flooring, including the following steps: S1, veneer preparation: use rotary cutting or planing to determine the thickness of the veneer; use sawing, cutting, cutting, planing Cutting, gluing, pressing or sewing one or a combination of several methods, fixed-width processing veneer; the thickness of the prepared veneer is 0.5mm-5mm, and the width is 80mm-200mm; S2, veneer sorting : Sorting the veneers according to their apparent quality. The veneers with beautiful surface, no decay, no blue stain, no moths, and no blemishes are selected as veneers. The outer surface; the rest of the veneers are used as the core board; S3, veneer treatment: firstly pretreat the sorted veneers, the pretreatment is one or more of drying treatment and high temperature heat treatment; then carry out Surface treatment, seven primers and two topcoats on the oute...

specific Embodiment approach 2

[0021] Specific Embodiment 2: Combining figure 1 Describe this embodiment, the manufacturing method of a lacquered wood-plastic composite floor described in this embodiment, in step S9, the two long sides and two short sides of the floor have grooves after milling, and the The two long side surfaces have corresponding grooves matching each other; the two short sides also have corresponding grooves matching each other; the others are the same as in Embodiment 1.

[0022] The technical effect of this embodiment is: through the use of the end milling machine and the double-end milling cooperating operation, the floor has grooves that can match each other, so that the floor products manufactured on the assembly line can be directly put into use, reducing manual intervention and processing errors. The production efficiency is improved; the grooves and grooves obtained have the characteristics of matching each other, and also ensure the matching and non-deformation in the thickness-...

specific Embodiment approach 3

[0023] Embodiment 3: Combining figure 1Describe this embodiment, the manufacturing method of a lacquered wood-plastic composite floor described in this embodiment, in step S3, through one or more methods in ventilated drying, high temperature heat treatment and plasma treatment, make the water content of the veneer lower than 5%, while reducing the surface energy of the veneer; the others are the same as in Embodiment 1.

[0024] The technical effect of this embodiment is: after the veneer is treated, the water content is controlled, and the surface energy is reduced, which is beneficial to the compounding of the veneer and the plastic film, and also improves the mechanical properties of the floor, reducing the possibility of air bubbles inside the floor Smaller, avoiding the stress concentration caused by the appearance of air bubbles; at the same time, because the surface energy of the veneer is reduced, it is beneficial to improve the interface bonding strength between wood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com