Intelligent warehousing carrier and intelligent warehousing system

An intelligent warehousing and truck technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of low operating efficiency, difficult and high-strength transportation, and heavy steel weight, and achieve a high degree of automation and lifting efficiency. High, easy to take and unload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

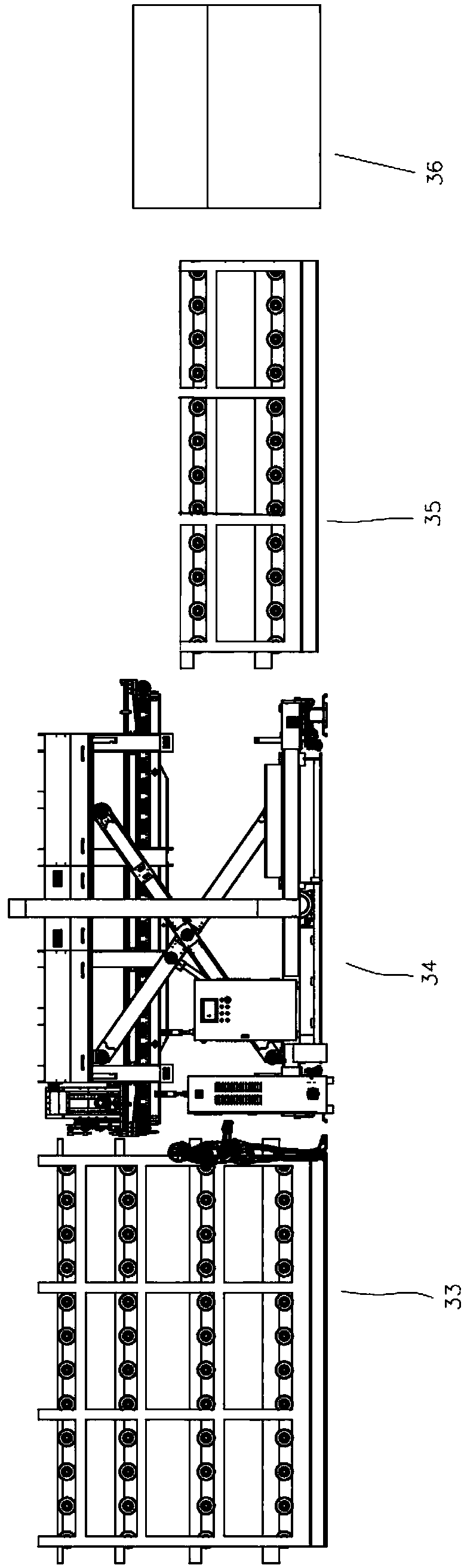

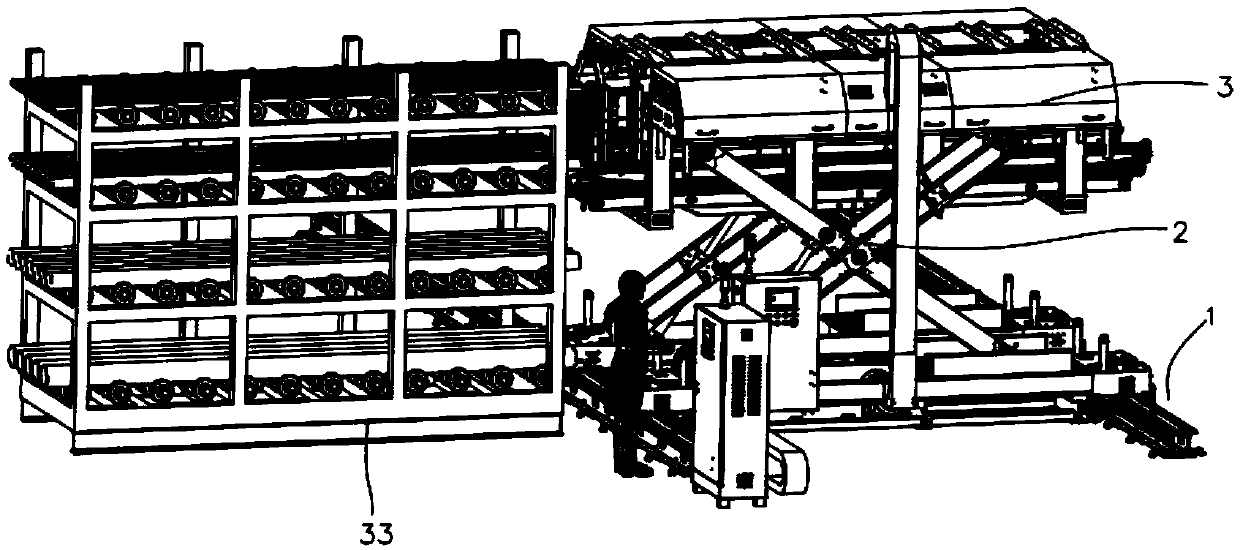

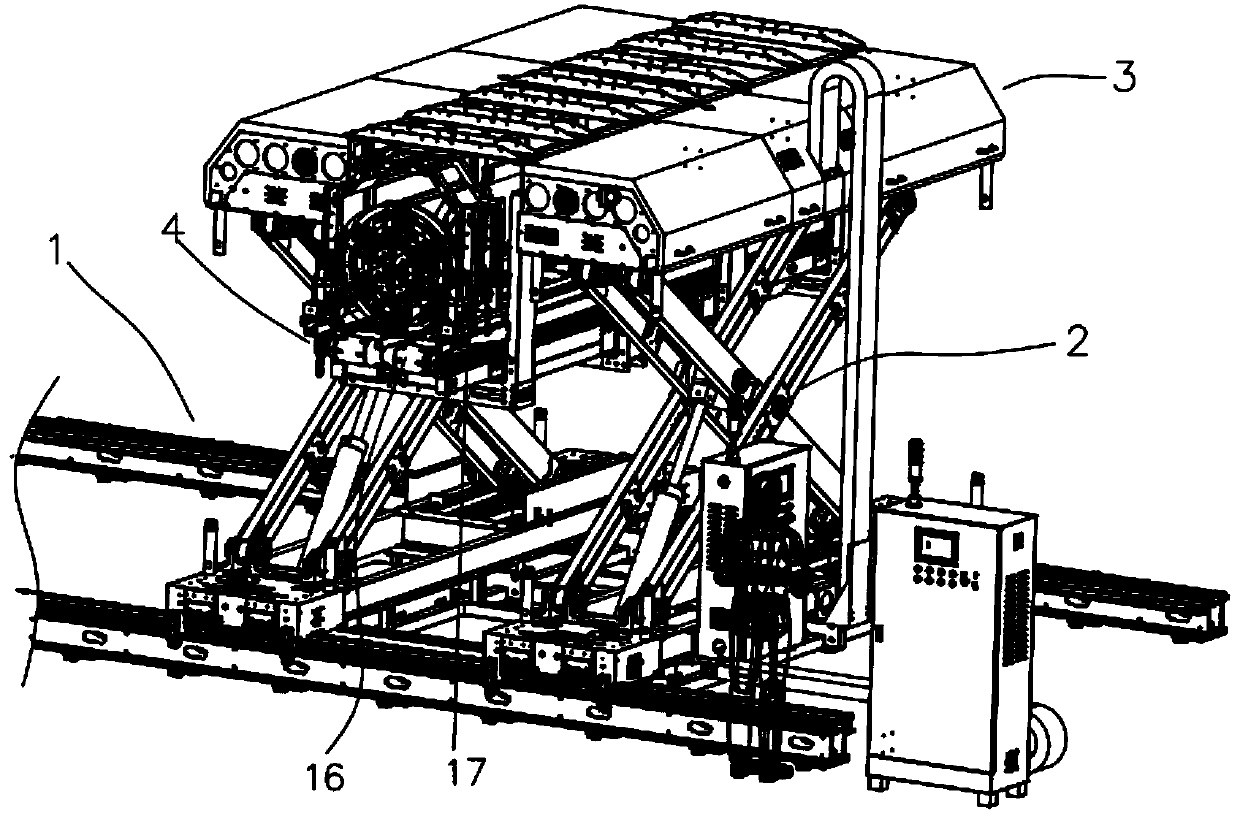

[0030] Such as figure 1 As shown, an intelligent transportation and storage system is disclosed, including an intelligent storage truck 34. One end of the intelligent storage truck 34 is provided with a shelf 33, and the other end is provided with a carrier 35, and one side of the carrier 35 is provided There is a cutting machine 36; the shelf 33 includes a number of feeding roller groups stacked up and down, and its working mode is that the intelligent storage truck 34 carries the side of the shelf 33, and the shelves 33 are arranged, and the intelligent storage truck 34 can be in front of the shelf 33 Move back and forth to obtain the goods on different shelves 33. Taking heavy steel as an example, the intelligent storage truck 34 pulls the steel from the rack to the truck. The tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap