Segmented-heating heat tube

A technology of heat pipes and heat exchange pipes, which is applied in the field of coil heat pipes, can solve the problems of low heat pipe efficiency, uneven heat transfer, and low heat transfer coefficient, and achieve the effects of improving heating efficiency, improving utilization efficiency, and strengthening heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

[0047] It is an object of the present invention to provide an electrically heated heat pipe such as Figure 4 -6 shown.

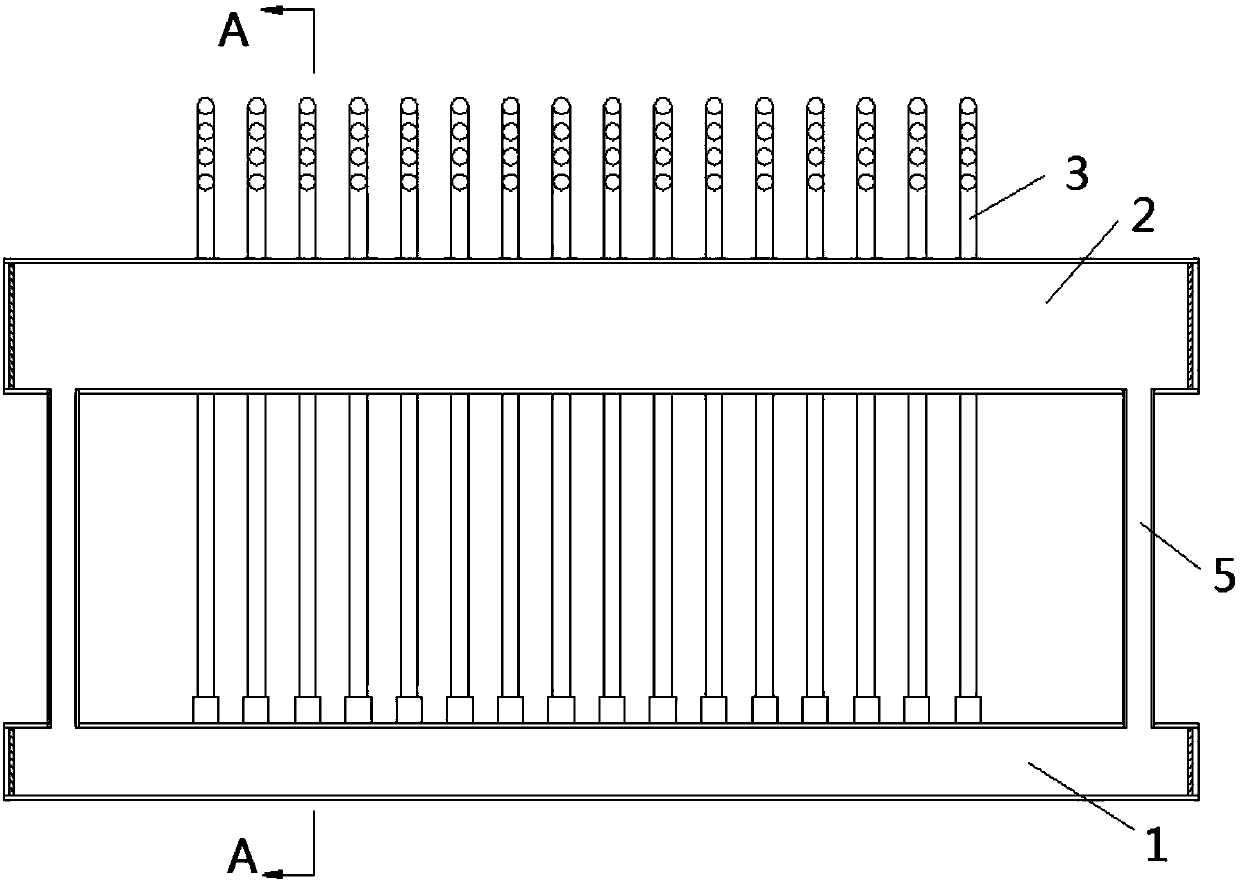

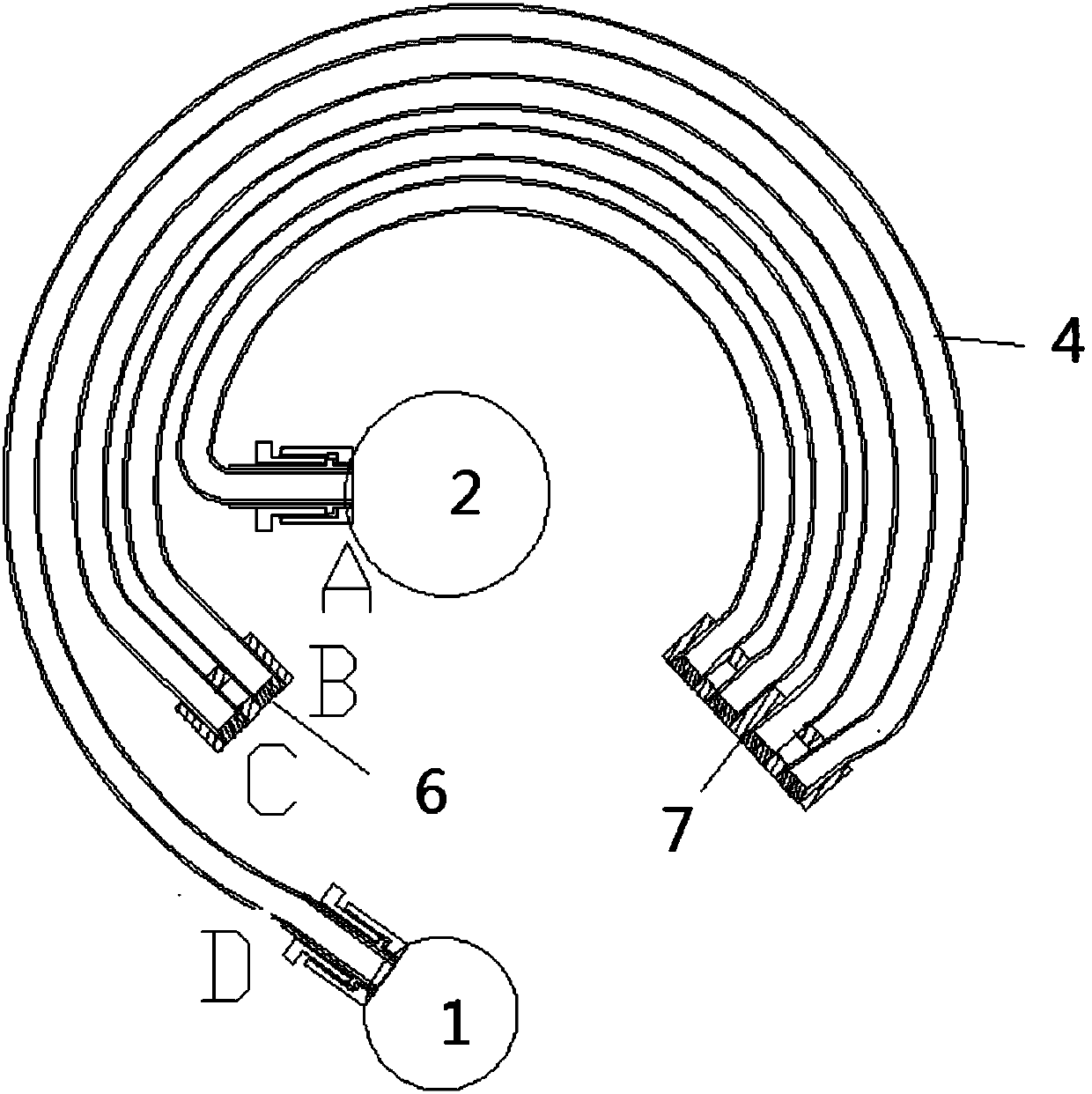

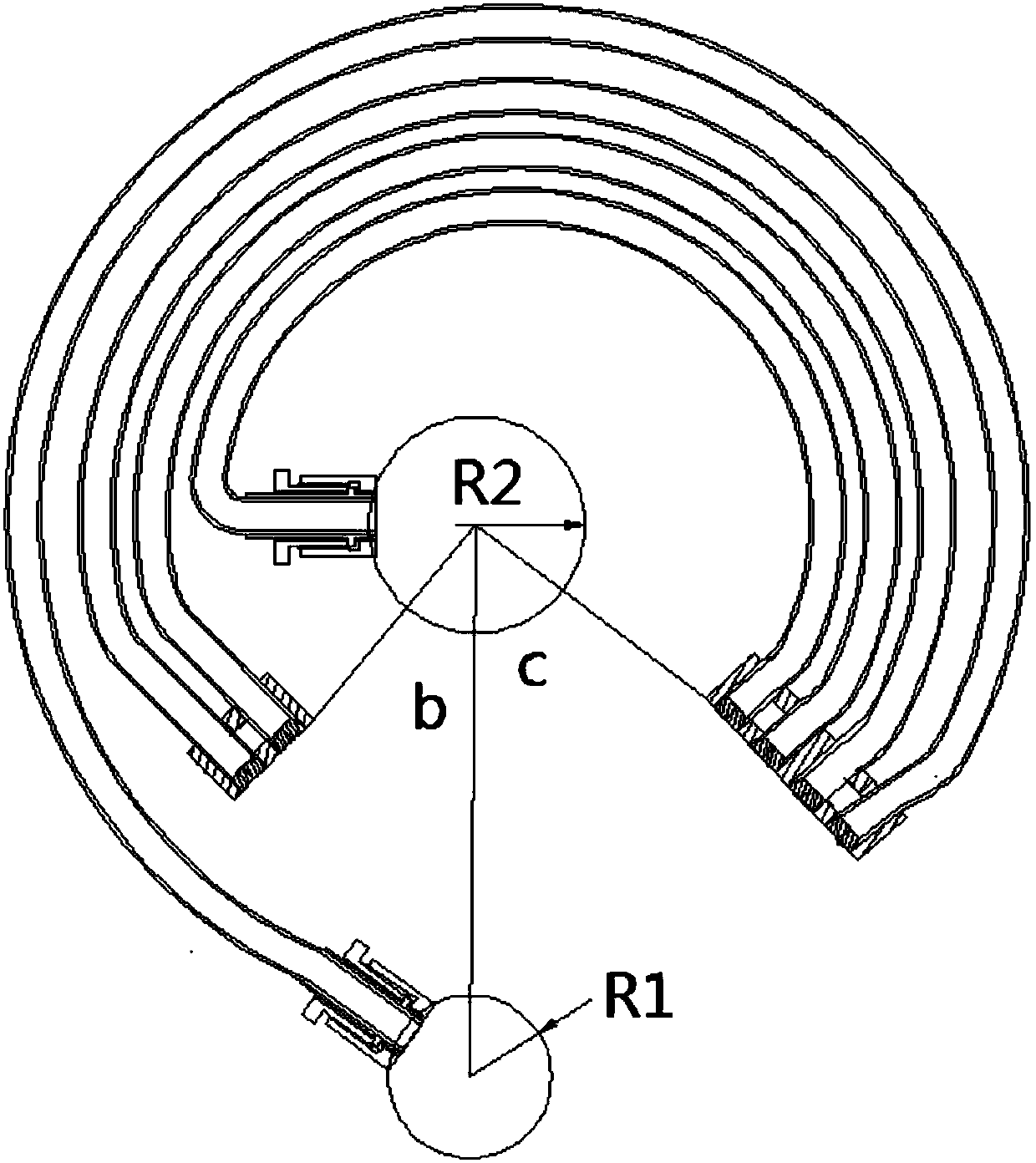

[0048] A heat pipe, comprising a lower header 1, an upper header 2, a heat exchange tube bundle and a return pipe 5, the heat exchange tube bundle communicates with the lower header 1 and the upper header 2, and the lower header 1 is an evaporation end , the condensation end includes the upper header 2, the fluid absorbs heat and evaporates in the lower header 1, condenses in the upper header 2, and the condensed fluid returns to the lower header 1 through the return pipe; the return pipe connects the lower header 1 and the positions of both ends of the upper header 2, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com