Rolling and kneading machine for pickling of meat products

A meat product and tumbler technology, which is applied in the field of tumbler for meat product marinating, can solve the problems of uneven seasoning, easy adhesion of meat materials, affecting the taste of meat materials, etc., and achieves convenient operation, easy mixing, guaranteeing effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

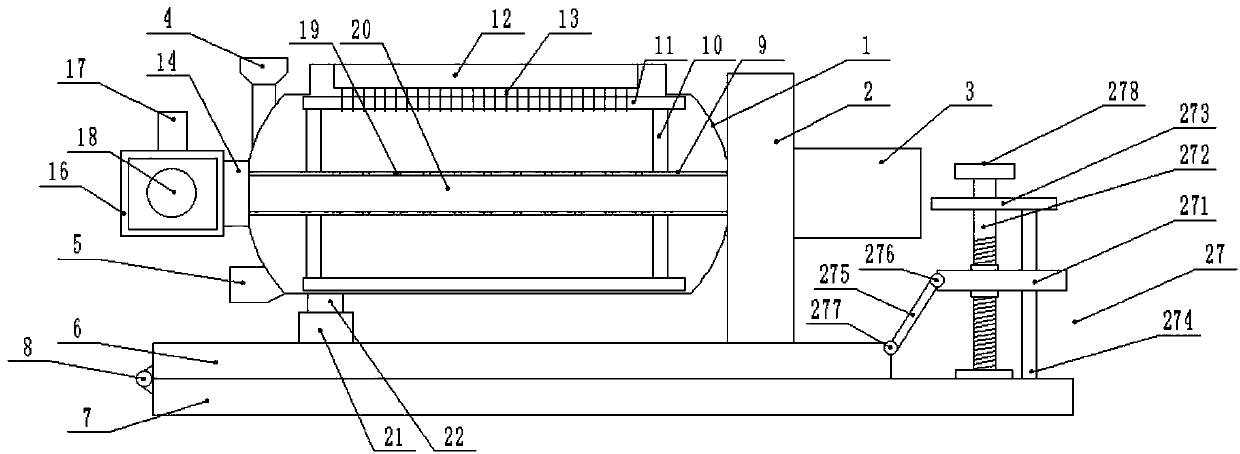

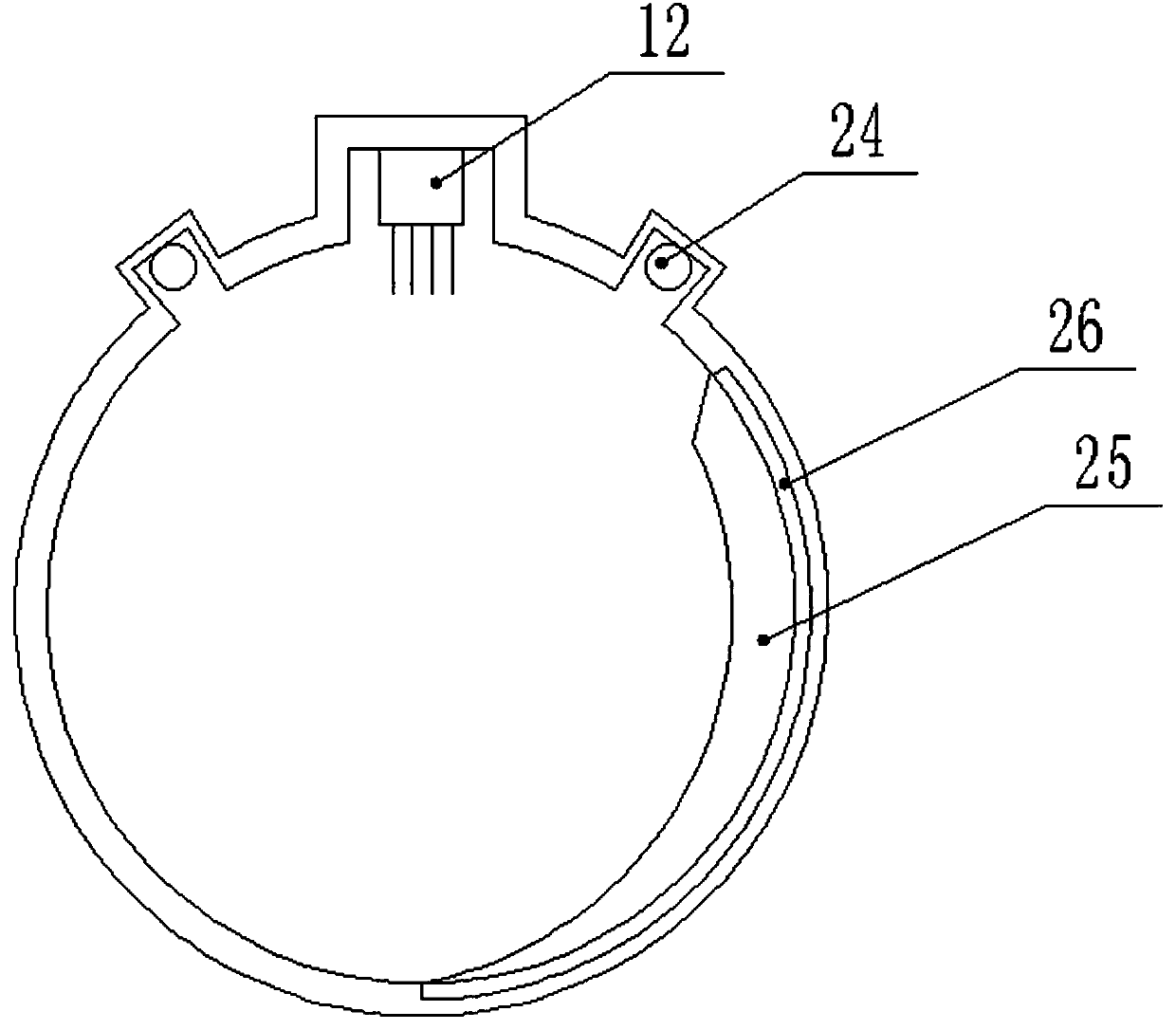

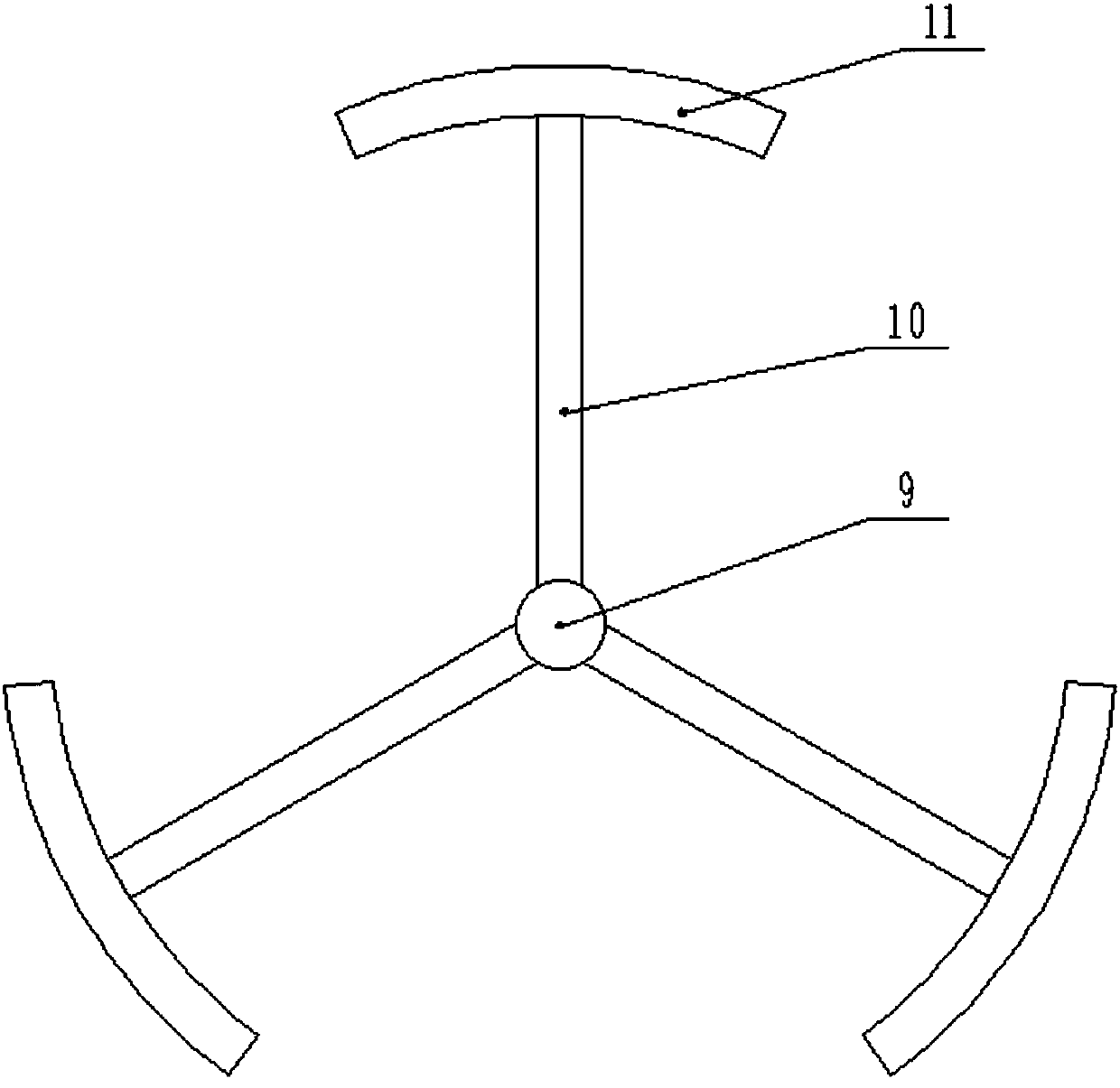

[0019] Please refer to the figure, in the embodiment of the present invention, a tumbler for marinating meat products includes a tank body 1, a bracket 2, a motor 3, a feed hopper 4 and a discharge pipe 5; the bracket 2 is fixed on the tank body 1, the lower end of the bracket 2 is fixed on the movable bottom plate 6, and the lower side of the other end of the tank body 1 is provided with a support seat 21 fixed on the movable bottom plate 6, and the support seat 21 is integrally provided with an arc-shaped support plate 22. The arc-shaped support plate 22 cooperates with the outer wall of the tank body 1, so that the tank body 1 is placed in the arc-shaped support plate 22, and is used to support the tank body 1, so that the tank body 1 is safe and stable; the bracket 2 is fixed with A horizontal motor 3, the output shaft of the motor 3 extends horizontally into the tank body 1, and the output shaft of the motor 3 coincides with the horizontal central axis of the tank body 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com