Paper shredding device with high stability

A high-stability, paper-shredding technology, applied to mixers with rotating stirring devices, transportation, packaging, and dissolution, can solve the problems of different time and energy, easy to be bumped or overturned, and inconvenient to use, etc., to achieve The effect of improving security function, improving stability, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

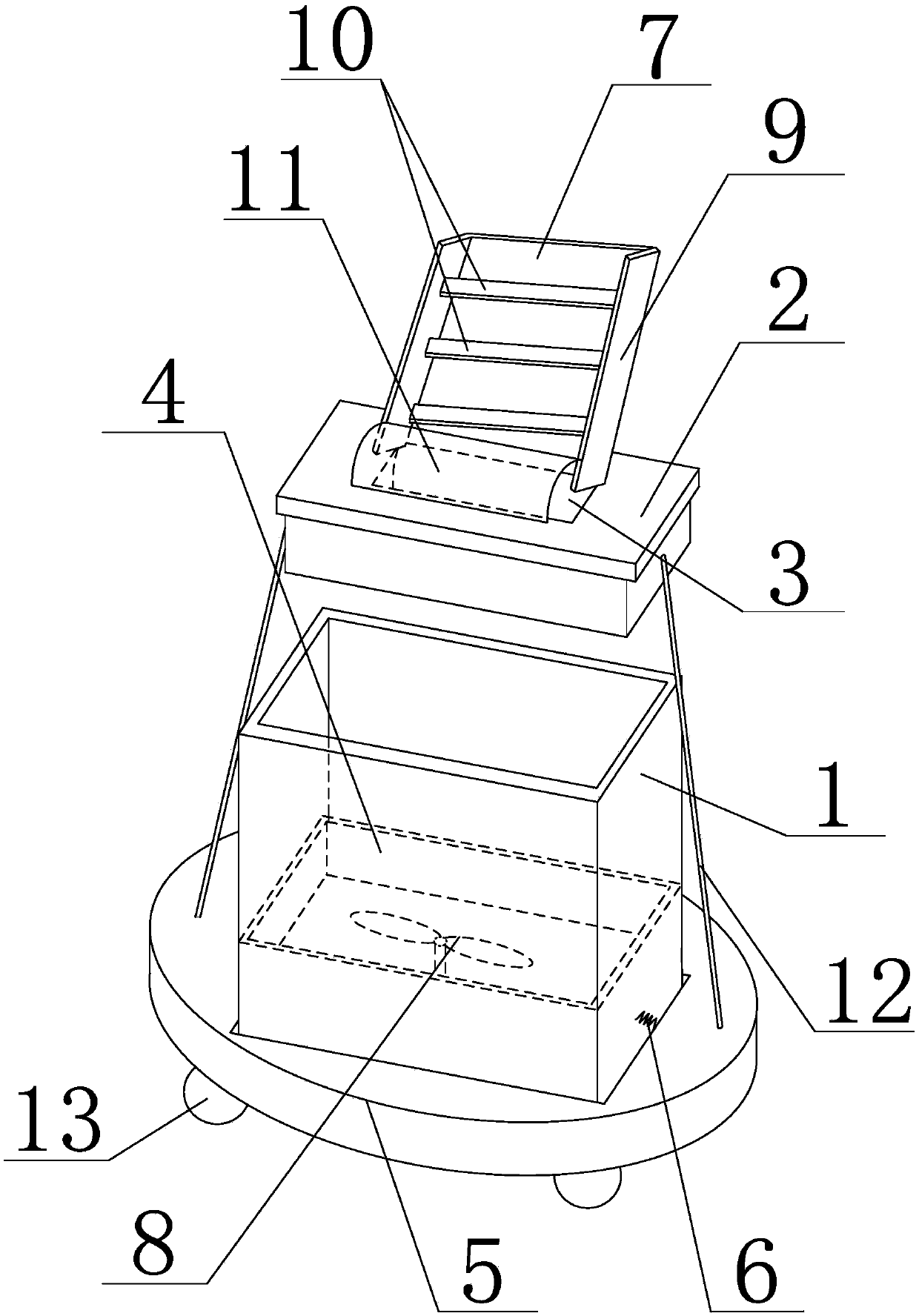

[0023] Such as figure 1 As shown, the document shredding device with high stability of the present invention includes a waste bin 1 and a machine cover 2 installed on the waste bin 1. The machine cover 2 is provided with a paper inlet 3 for putting paper to be shredded. Below the paper inlet 3 in the cover 2, there is a cutting knife with a knife tip, which cuts the paper under the drive of the motor; The stirring paddle 8 is filled with water, the bottom of the waste bucket 1 is provided with a cylindrical fixed base 5, the fixed base 5 is provided with a placement groove, the waste bucket 1 is arranged in the placement groove, and the outer wall of the waste bucket 1 is in contact with the The inwalls of the placement grooves are connected by shock-absorbing springs 6, and the both sides of the waste bin 1 on the fixed base 5 are respectively provided with support rods 12 which are arranged obliquely, and the tops of the support rods 12 are connected with the side walls of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com