Intelligent sorting system for batch detection of pearl shapes based on machine vision

A technology of batch detection and machine vision, applied in sorting and other directions, can solve problems such as complex feeding mechanism, light reflection and refraction, and difficult production, and achieve the effects of reasonable missing detection recovery mechanism, simple device structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

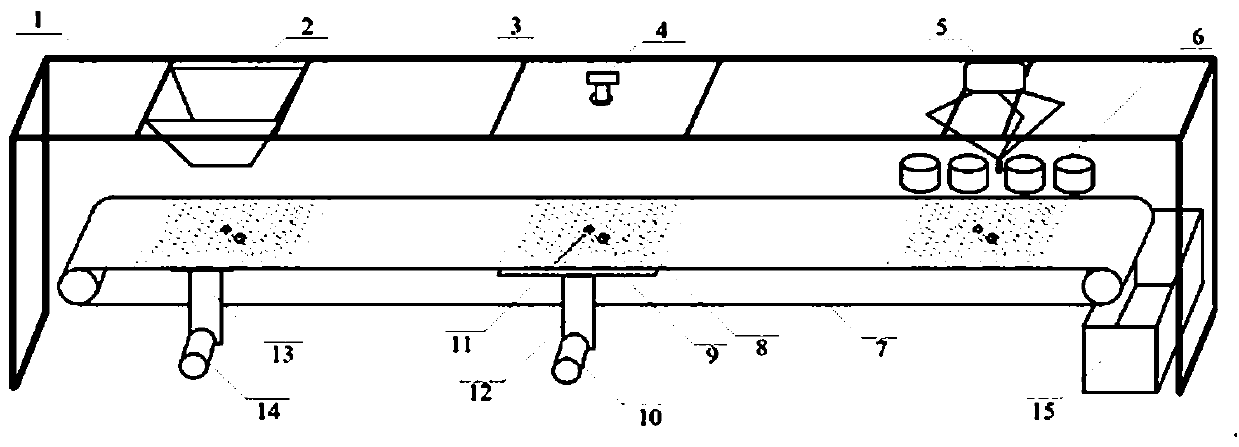

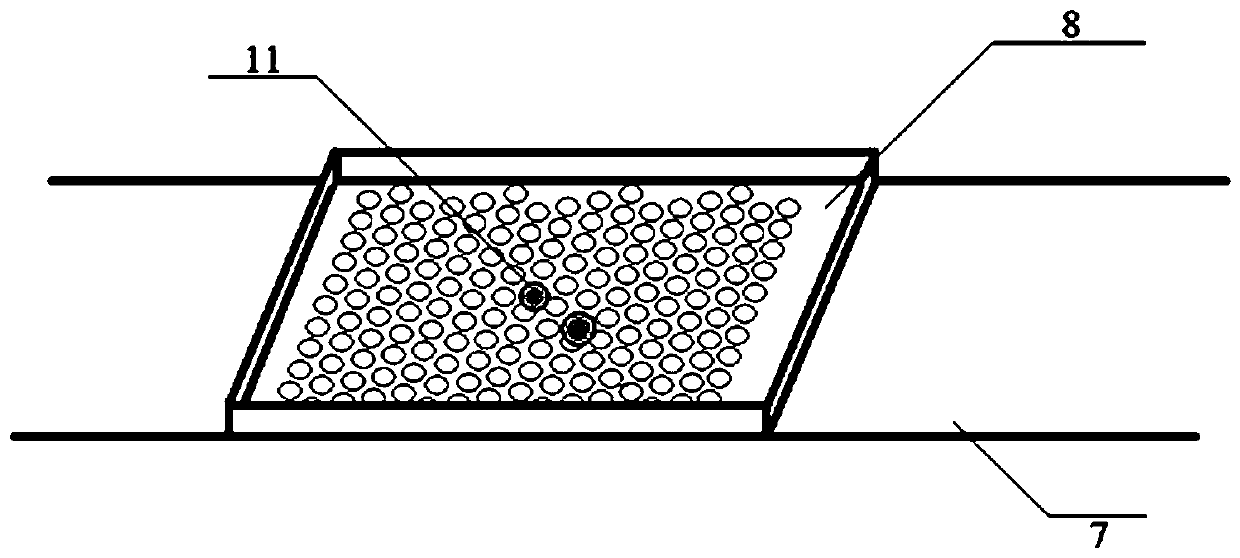

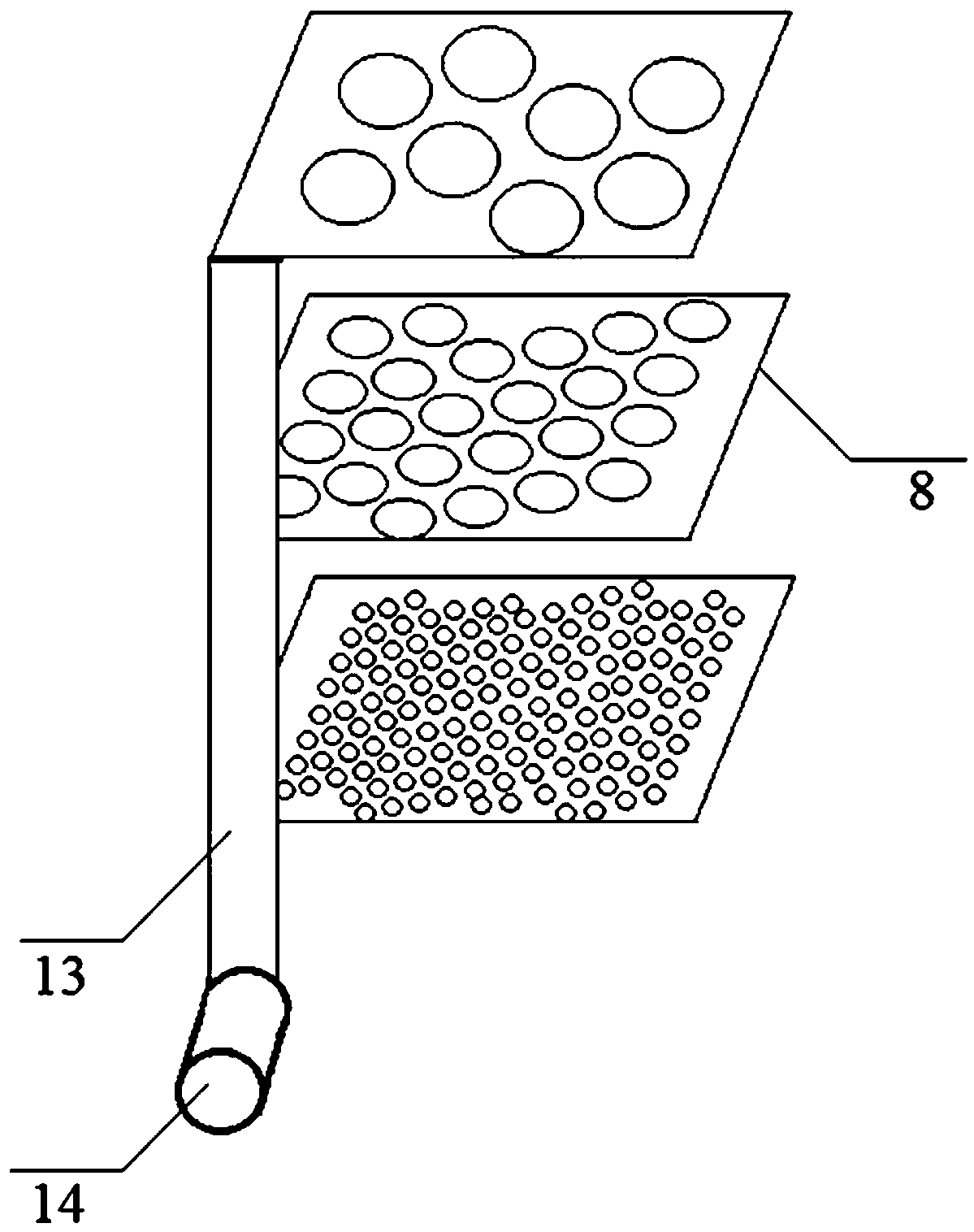

[0023] refer to figure 1 As shown, the intelligent sorting system based on machine vision batch detection of pearl shapes includes a frame-shaped support 1 for carrying equipment, and one end of the frame-shaped support 1 is provided with an upper surface for distributing pearls 11 in a single layer (size that can be sieved). There is a visual detection mechanism in the middle for rolling pearls 11 and collecting multi-surface images of pearls 11 in batches, and a sorting mechanism for sorting pearls 11 into different sorting containers 15 at the other end, and a conveyor belt 7 at the bottom , the conveyor belt 7 is provided with upper three evenly distributed upper mold plates 8; The conveyor belt 7 contacts; the visual detection mechanism includes a camera 4, an LED surface light source 3, a computer, a drive motor 10, a track connecting rod 12, and a lower mold plate 9, wherein the LED surface light source 3 can illuminate the upper mold plate 8 everywhere. Bright, no sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com