Automatic workpiece conveying device

A technology of automatic conveying and workpiece, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of long working time, labor consumption, large quantity, etc., to achieve stable and reliable accuracy and improve labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

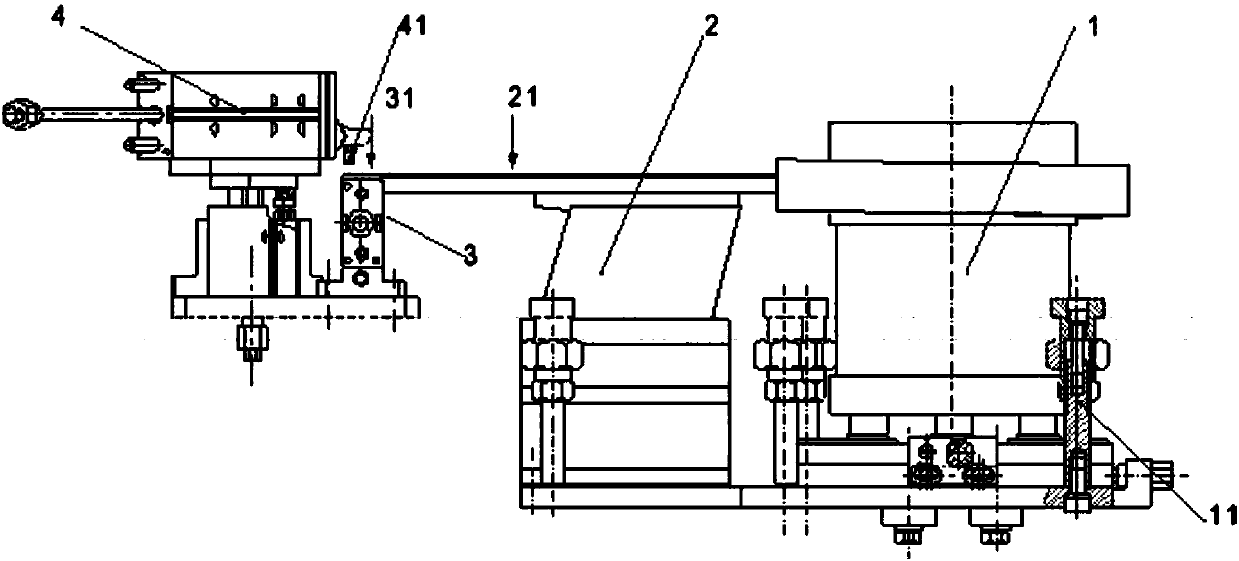

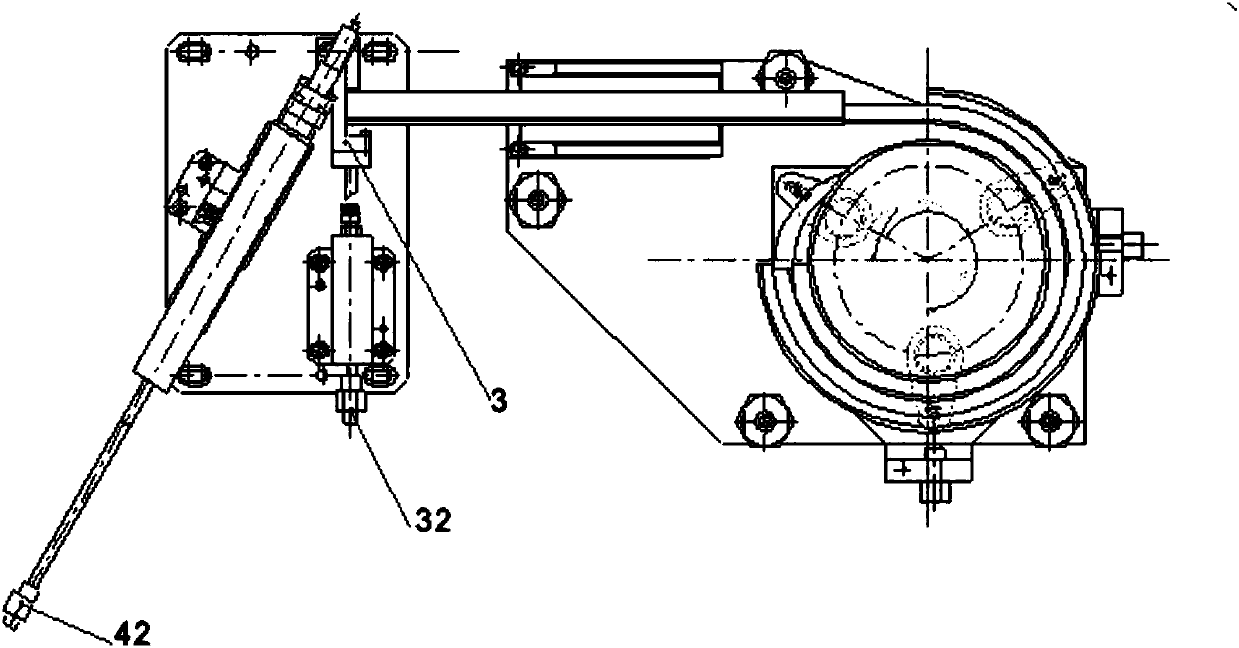

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] The workpiece automatic conveying system includes a vibrating plate 1, a vibrating transmission tank 2, a material holding tank 3 and a manipulator 4. The vibrating plate 1 is installed on the first base, which is a disc with a spirally descending annular groove, and is composed of Driven by a vibrator to vibrate, the support tank 3 and the manipulator 4 are installed on the second base, and the two ends of the vibration transmission tank 2 are respectively erected on the first base and the second base, and the vibration transmission The input end of the tank 2 is connected with the output end of the vibration plate 1, the output end of the vibration transmission tank 2 is connected with the input port of the support tank 3, and the vibration transmission tank 2 is provided by another vibrator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com