Air cylinder driving rail type foam scrubbing rod releasing device

A cylinder-driven, delivery device technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of high labor intensity, slow drop of bubble row rods, hidden safety hazards of operators, etc., to improve work efficiency Efficiency, increase delivery speed, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

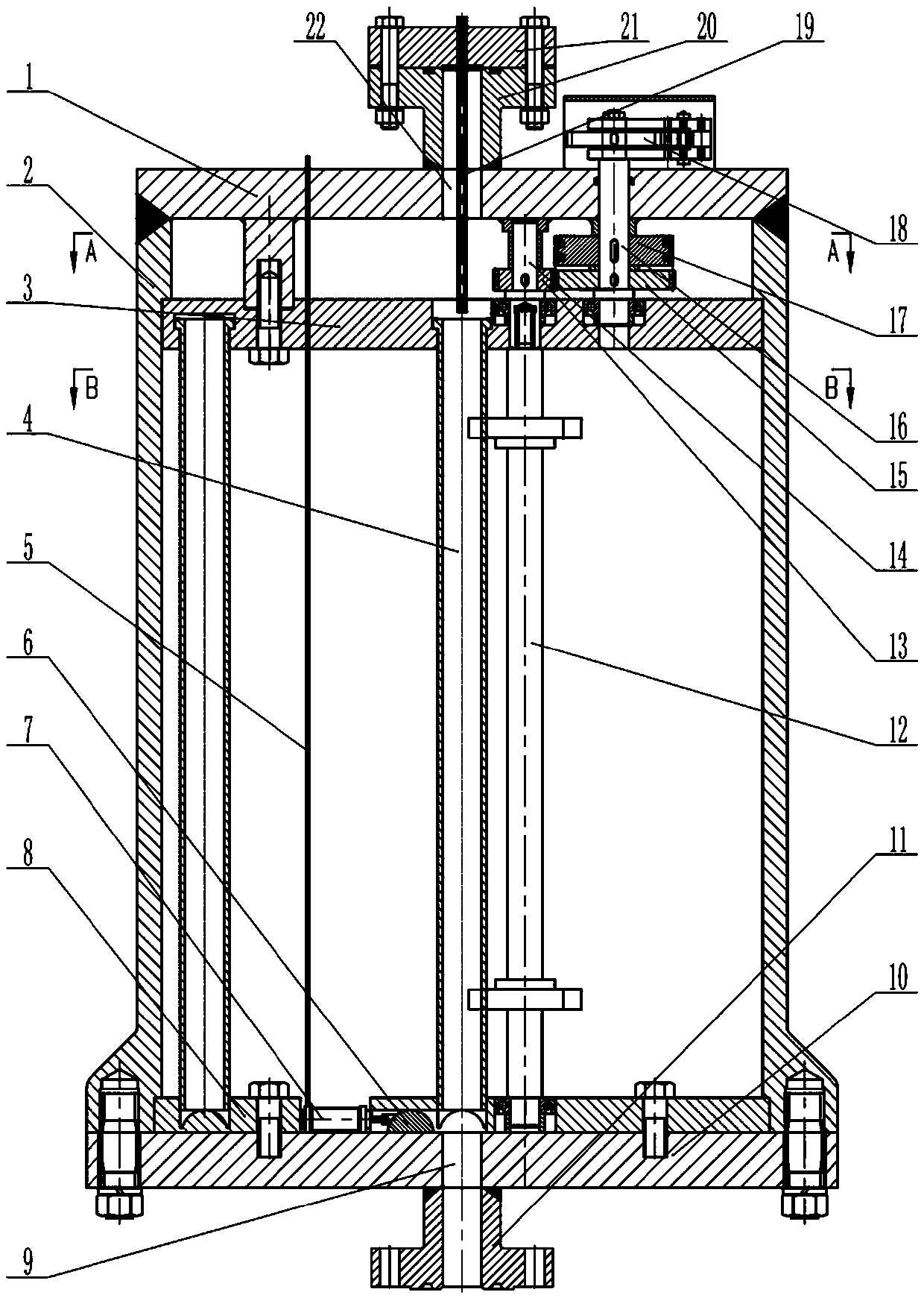

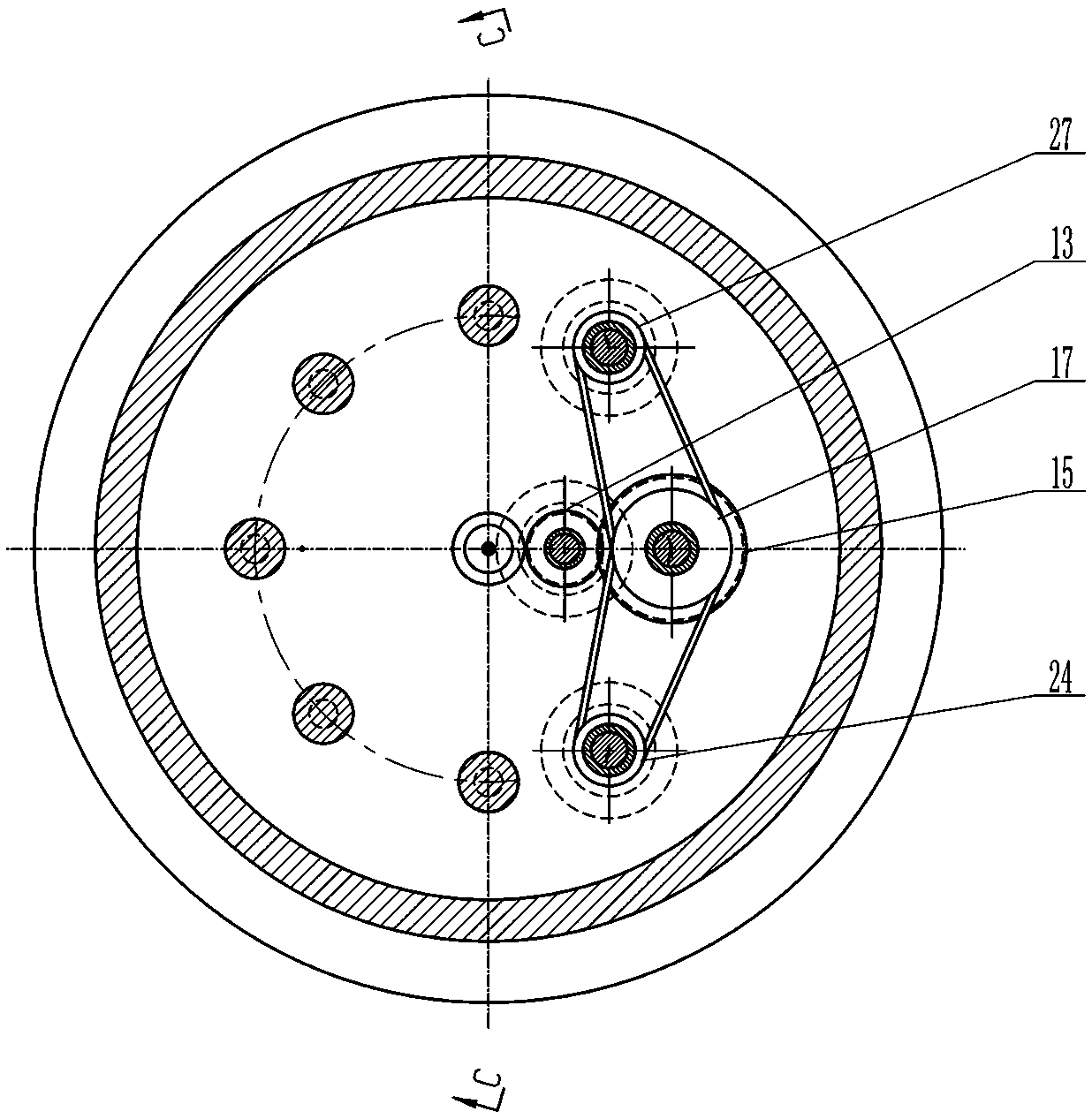

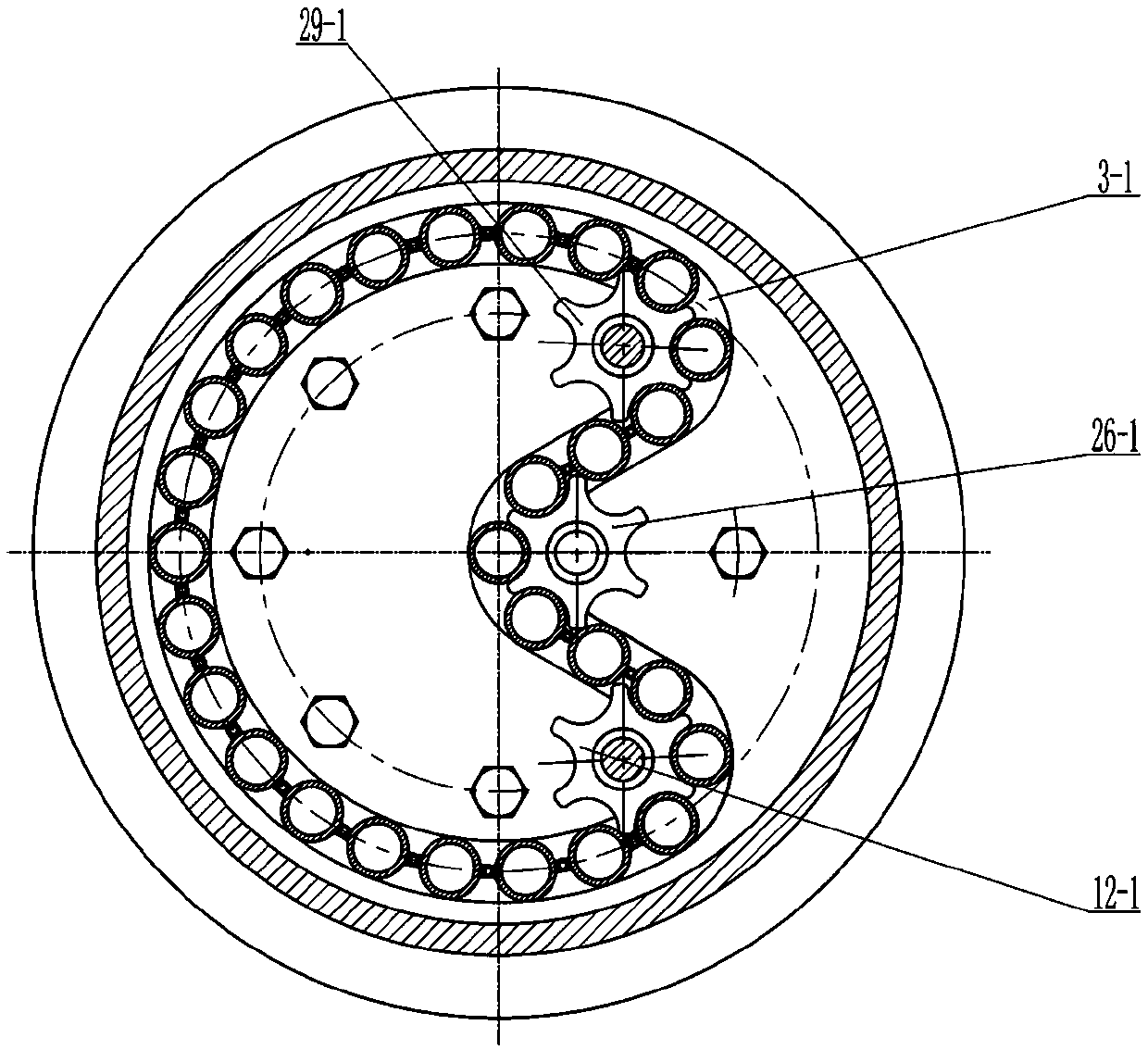

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] like figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6As shown, a cylinder-driven track-type foam row rod feeding device consists of an upper cover plate 1, a housing 2, an upper limit wheel 3, a charging cylinder 4, an air pipe 5, a stopper 6, a stopper cylinder 7, and a lower limiter wheel 8. Lower cover plate 10, wellhead connecting flange 11, drive shaft 12, pinion gear 13, pinion gear shaft 14, large gear 15, large gear shaft 16, large pulley 17, ratchet mechanism 18, air nozzle 19, upper method Lan 20, flange cover 21, indexing cylinder 23, small pulley I24, small pulley shaft I25, driven shaft I26, small pulley II27, small pulley shaft II28 and driven shaft II29 form. The upper cover plate 1 is installed above the shell 2 and connected with the shell 2 by welding. The center of the upper cover plate 1 is provided with a charging hole 22. The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com