High-strength supporting and protection structure of subway tunnel and construction method thereof

A support structure and high-strength technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as difficult construction, manual construction accuracy cannot meet the requirements, inconvenient transportation, etc., and achieve convenient construction and reinforcement effects And the effect of excellent carrying capacity and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the specific embodiments and drawings.

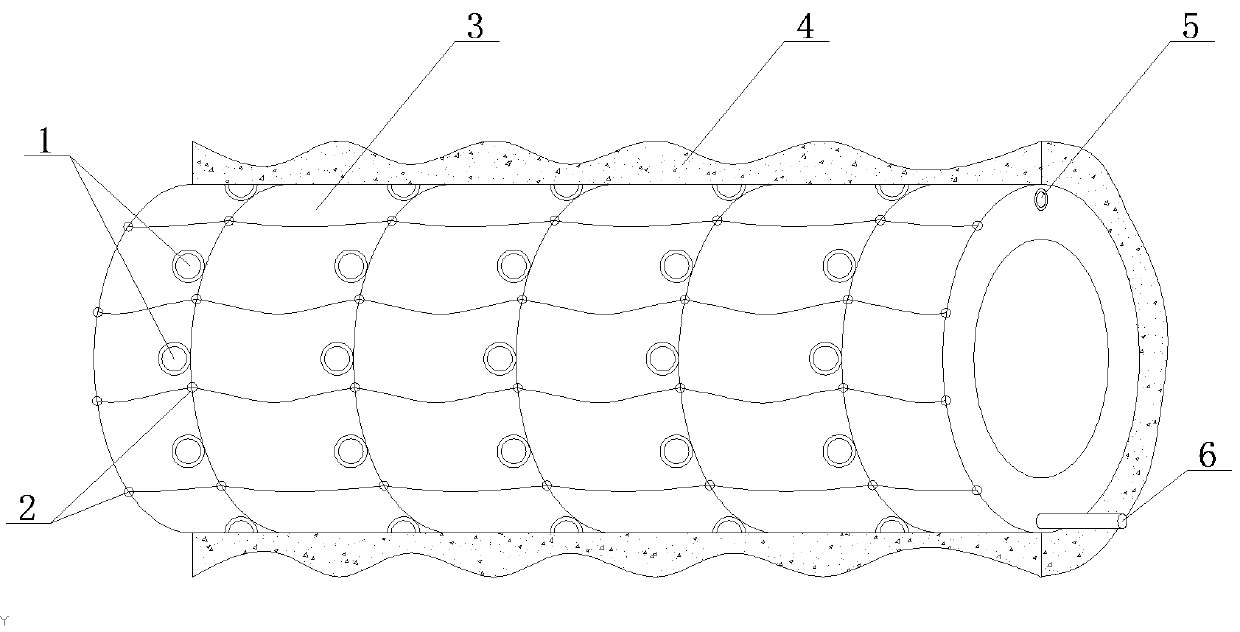

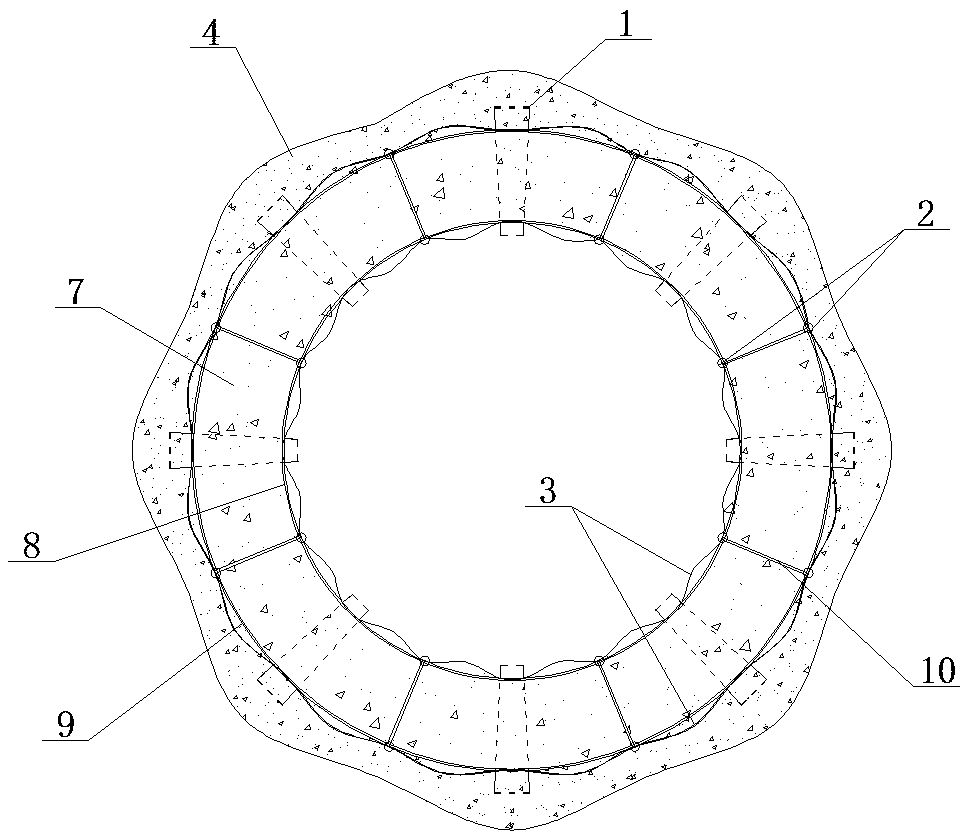

[0031] Such as figure 1 , figure 2 As shown, a high-strength support structure for a subway tunnel includes a bag formwork 3, an inner support bar 8, an outer support bar 9, a filling concrete 7, and a poured stone body 4. It is characterized in that the bag formwork 3 is made of filament A permanent formwork made of fiber cloth, the bag formwork 3 is divided into two layers inside and outside, the two-layer formwork is sealed at both ends, and one end of the seal is provided with a grouting port 6 and an air vent 5; the bag formwork 3 is provided with several The short grouting pipe 1 connecting the inner and outer two-layer formwork, the short grouting pipe 1 is distributed in a ring shape along the cross section of the bag formwork 3; the inner support steel bar arranged in a ring shape is arranged inside the bag formwork 3 near the short gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com