Flap-type breaking wave simulating device

A technology of breaking waves and flapping boards, which is applied in measuring devices, testing of machines/structural components, instruments, etc., can solve the problems of inability to realize automation, convenient operation, single wave making, etc., and achieve low cost, wide application range, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

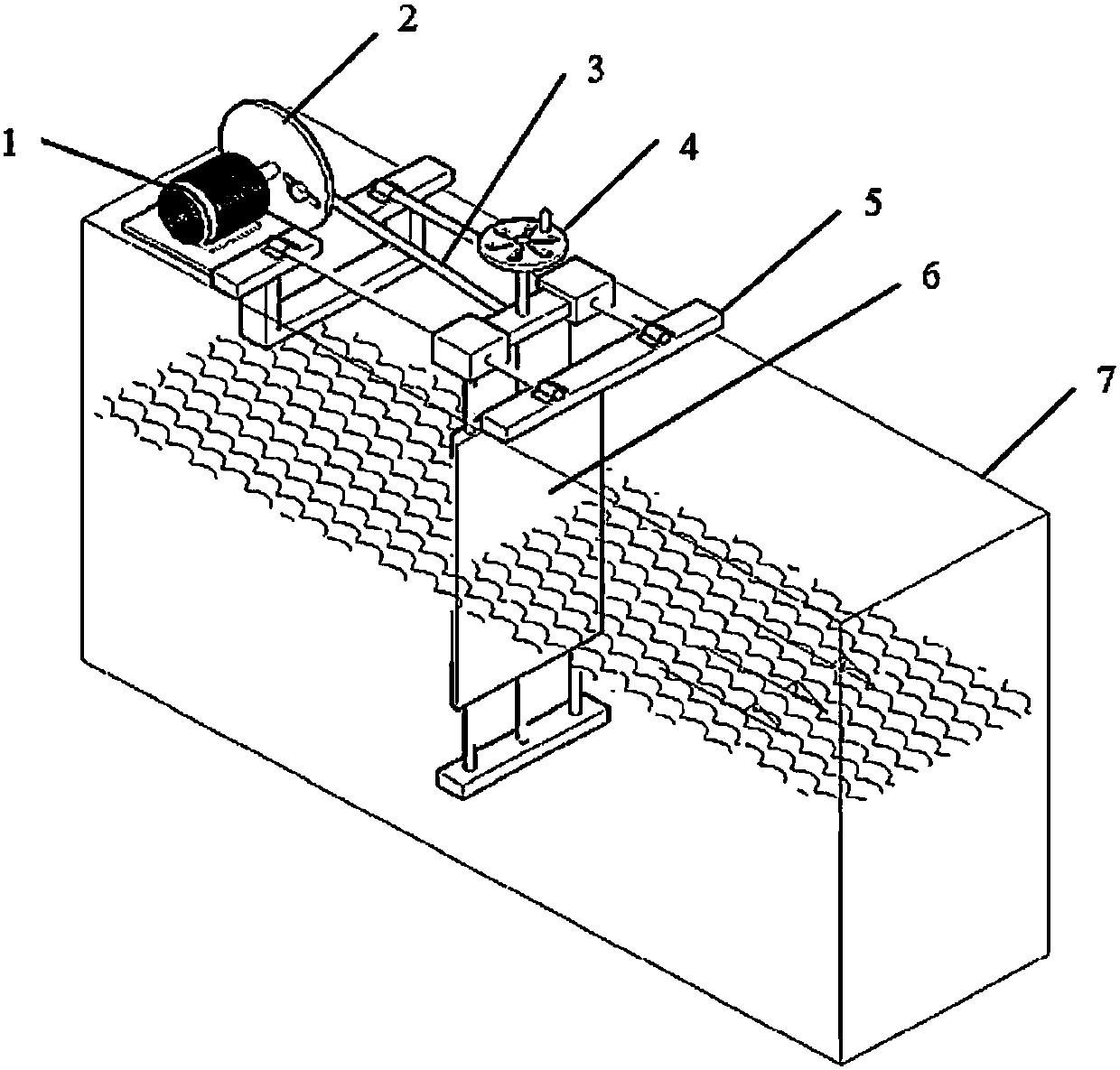

[0019] Such as figure 1 As shown, a slapping device for simulating breaking waves includes a drive motor 1, a transmission assembly, a lifting screw, a slapping plate 6 and a support bracket 5, wherein the support bracket 5 is fixedly installed above the wave-making tank 7, and the slapping plate 6. It is movably connected under the supporting bracket 5 through the lifting screw and placed in the wave-making water tank 7. The lifting screw placed on the supporting bracket 5 is provided with a lifting handle 4. The lifting handle 4 is a compass structure with a handle. , the rotation of the lifting handle 4 adjusts the depth of the beating plate entering the water tank; the beating plate 6 is perpendicular to the supporting bracket 5, the driving motor 1 is fixed on the supporting bracket 5, and the driving motor 1 is connected to the beating plate 6 through the linkage rod 3 transmission assembly. connected, thereby driving the beating plate 6 to perform reciprocating motion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com