Fault ride-through control system for alternating-current excitation power supply

A technology of AC excitation and control system, applied in the direction of control system, vector control system, AC network circuit, etc., can solve the problems of unfavorable DFIG control of doubly-fed generators, without considering the AC excitation power supply, etc., to achieve the suppression of DFIG rotor overcurrent, The effect of suppressing rotor overcurrent and eliminating negative sequence current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following embodiments can be used in combination, and the present invention can be implemented in various forms, and is not limited to each specific embodiment described in this specification. These embodiments are provided. The purpose of the example is to describe the disclosure content of the present invention more thoroughly and comprehensively, so as to facilitate understanding.

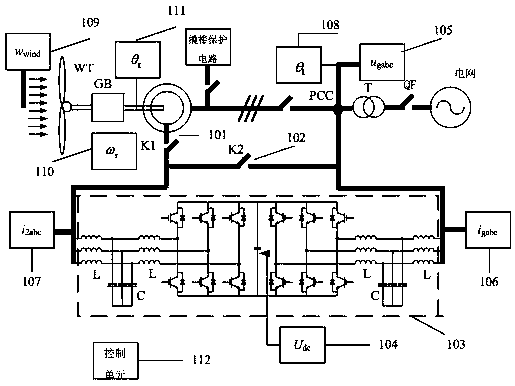

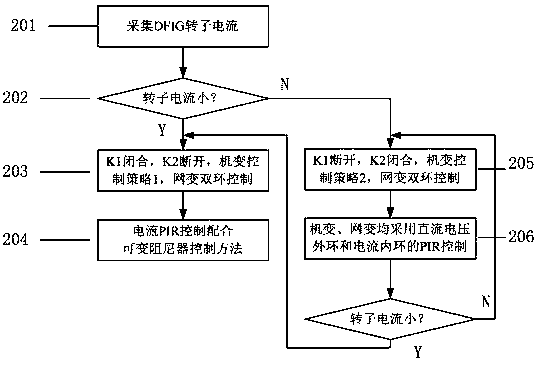

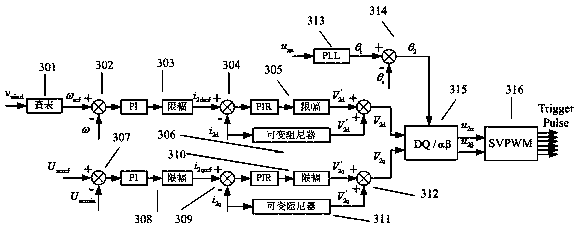

[0033] An example of the present invention is an AC excitation power fault ride-through control system, which is mainly used for double-fed wind turbines. The AC excitation power fault ride-through control system is such as figure 1 As shown, it includes a three-phase electronic switch K1 101, a three-phase electronic switch K2 102, an AC excitation power supply main circuit 103, a DC voltage measurement unit 104, a three-phase AC voltage measurement unit 105,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com