Pulse negative pressure laser enhanced-type lock hole TIG welding device

A welding device and enhanced technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high laser reflectivity of materials, poor joint performance, unstable welding quality, etc., and achieve a refined weld structure , The welding process is stable, and the effect of realizing the quality of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments.

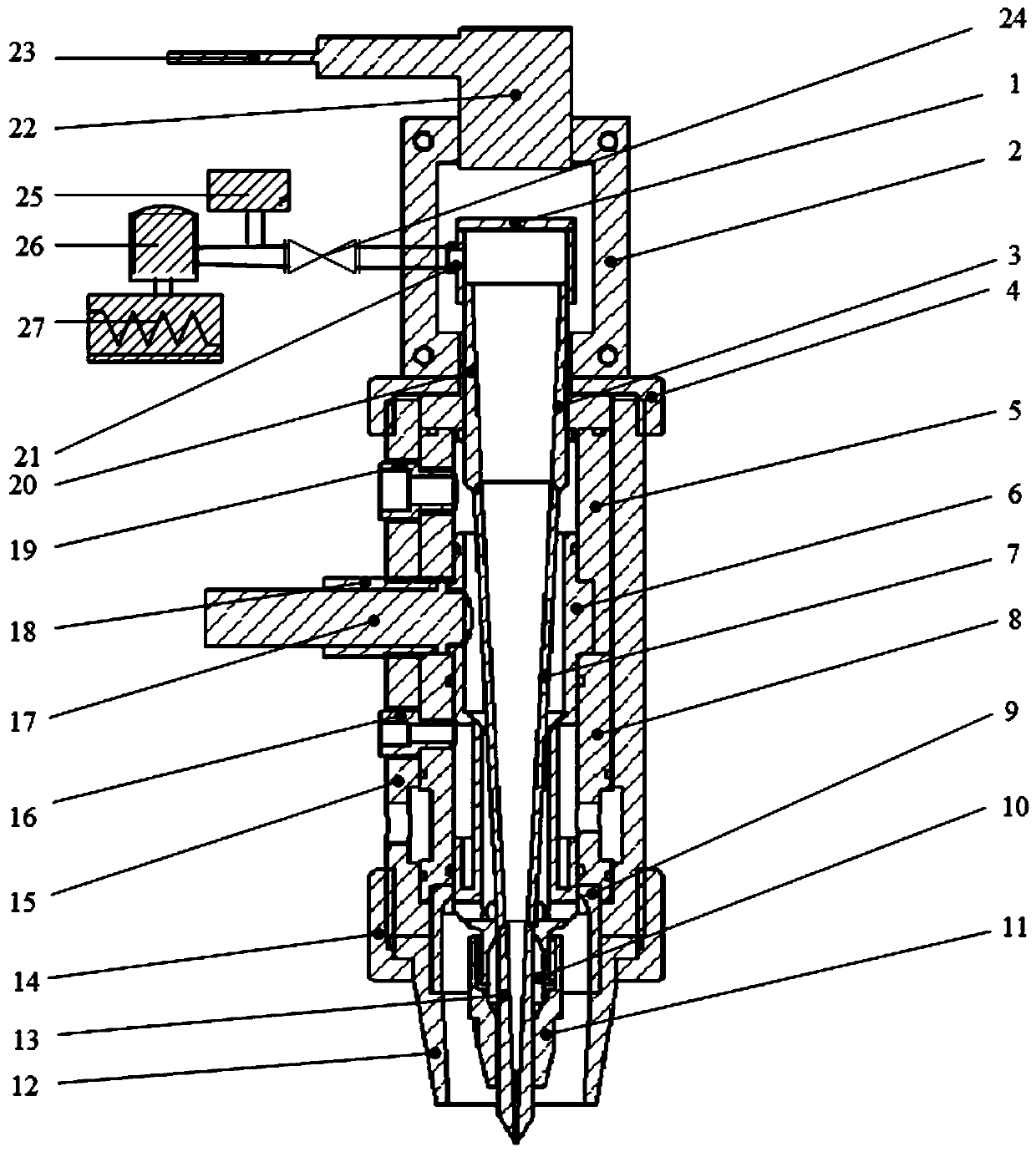

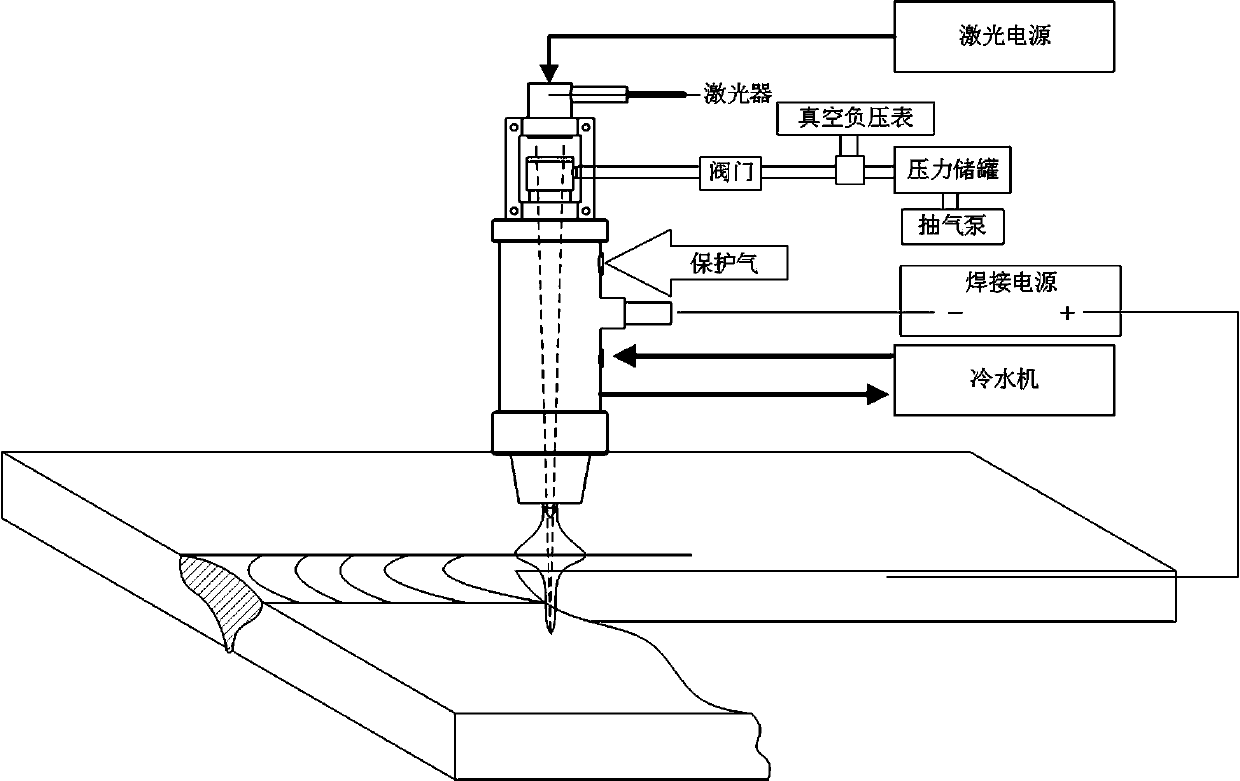

[0025] like figure 1 As shown, the pulsating negative pressure laser enhanced keyhole TIG welding device includes high light transmission glass 1, laser fixing frame 2, top cover plate 3, upper nut 4, upper insulator 5, conductor 6, vacuum negative pressure tube 7 , lower insulator 8, isolation ring 9, tungsten pole clip 10, lock nut 11, gas cover 12, hollow tungsten pole 13, lower end nut 14, welding torch outer body 15, adapter 16, wiring rod 17, conductive rod insulating sleeve 18 , Gas adapter 19, insulating gas pipe 20, vacuum negative pressure connector 21, laser 22, optical fiber 23, pulse electromagnetic valve 24, vacuum pressure gauge 25, pressure storage tank 26, air pump 27. The hollow tungsten electrode 13 is clamped by the tungsten electrode clamp 10, and fixed on the conductor 6 through the lock nut 11. The conductor 6 is assembled in the outer body 15 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com