Manufacturing method of shoe shell and three-piece pattern shoe making mold

A mold and molding technology, which is applied in the preparation method of shoe shells and the field of molds, can solve the problems of large glue usage, difficult to stabilize quality, and insufficient environmental protection, and achieve the effect of fast molding, fast speed, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of shoe shell, comprises the following steps:

[0046] (1) Prepare the rubber for shoe shells, and take the rubber for shoe shells of the required amount for shoemaking;

[0047] (2) Cut the shoe shell rubber obtained in step (1) into a strip or square size, so that the rubber can be properly arranged in the three-open shoe mold in the subsequent operation;

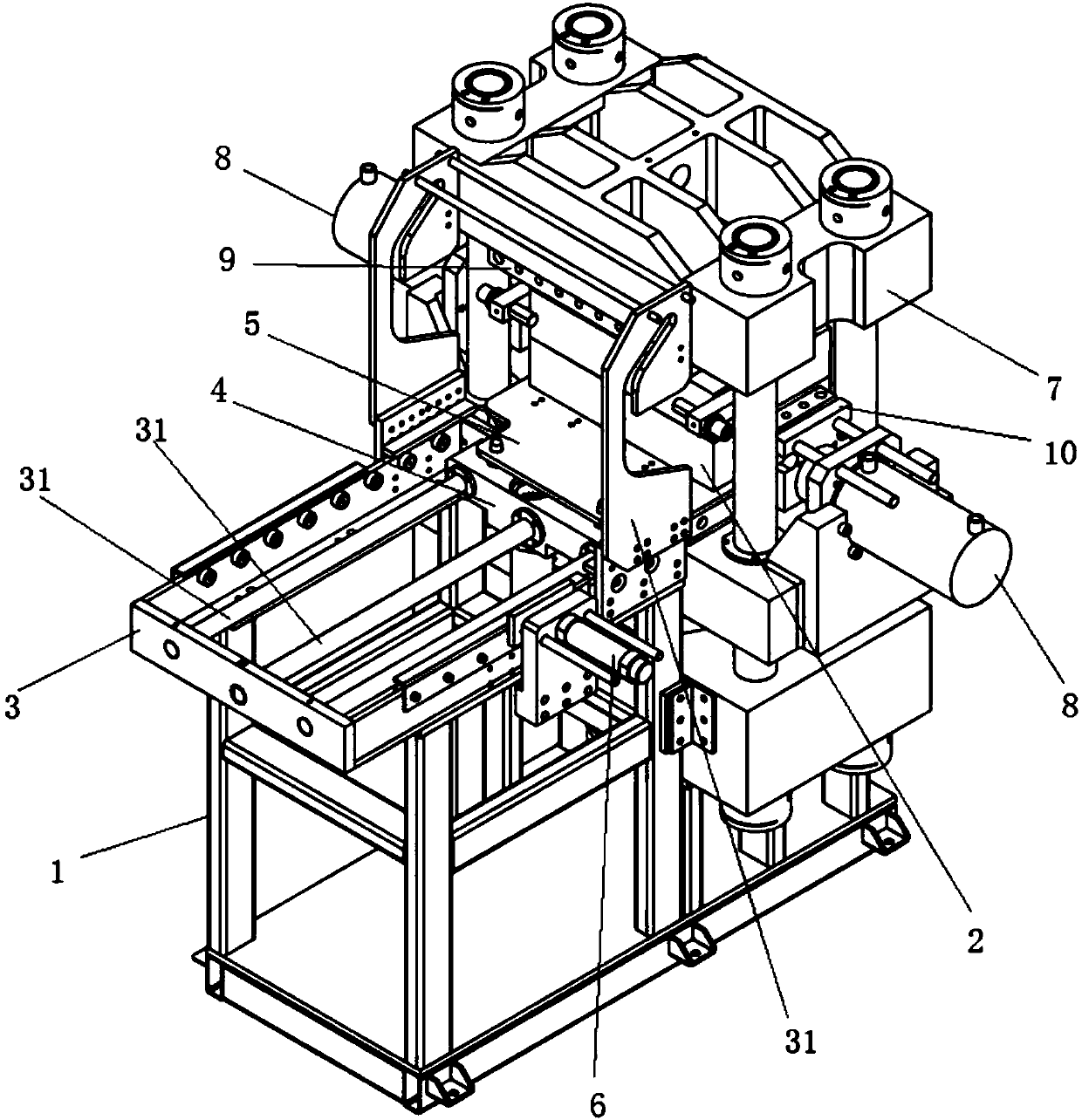

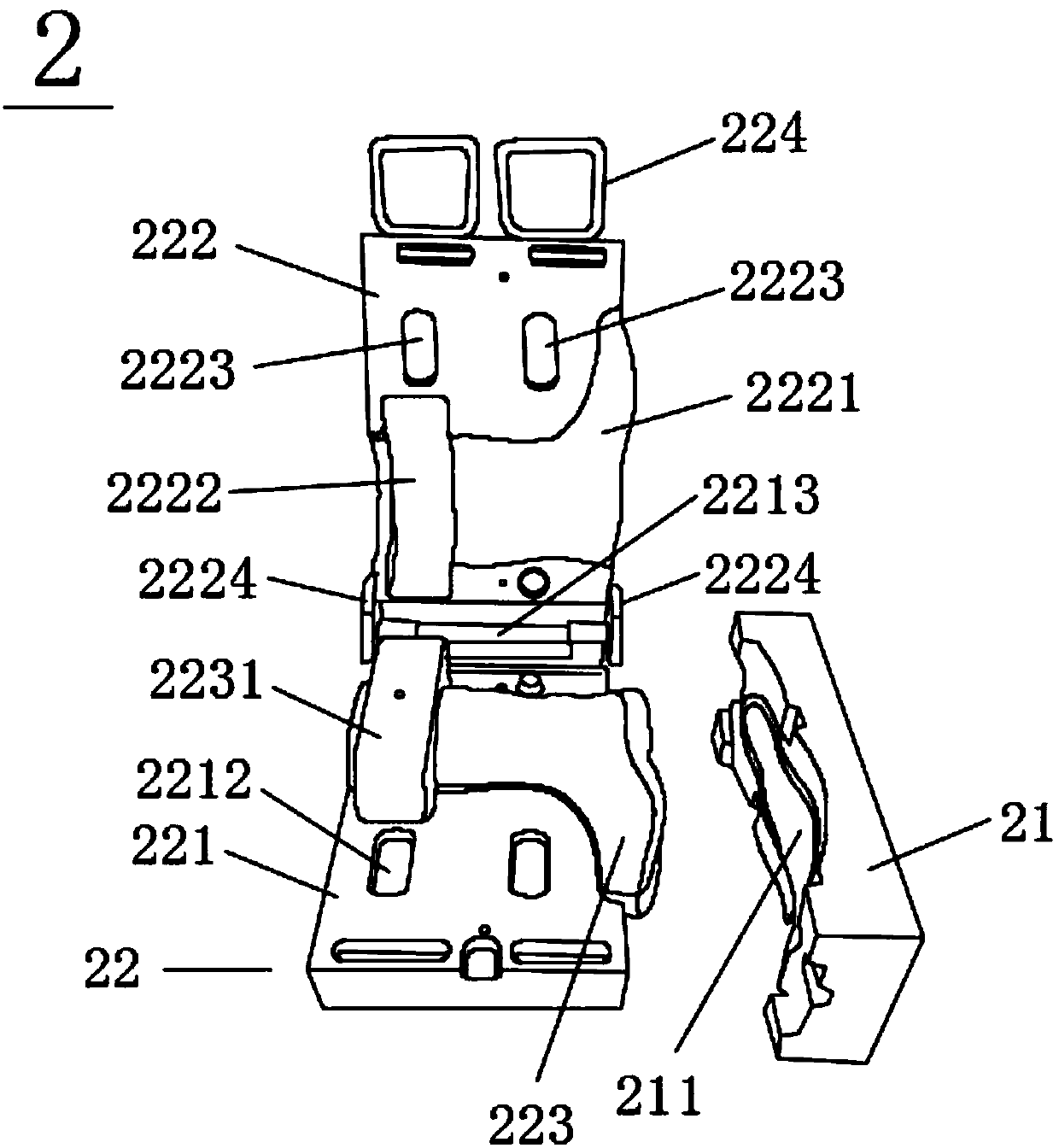

[0048] (3) if figure 2 and image 3 Shown is provided with three mold-opening shoe molds, which includes a machine platform 1 and a molding die 2 arranged on the machine platform 1, such as figure 2As shown, the forming mold 2 includes a bottom mold 21 movably arranged on the machine platform 1, and a mold main body 22 slidably arranged on the machine platform 1 and positioned at the side of the bottom mold 21, wherein the mold main body 22 includes A mold lower template 221, a mold upper cover plate 222 covered on the mold lower template 221, and a ...

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is:

[0072] The following formula is used for preparing shoe shell rubber in the step (1): 4 parts of SBR-1502 butadiene rubber, 8 parts of BR-9000 butadiene rubber, 18 parts of 3L natural rubber, 16 parts of white carbon black, dioxalic acid 2 parts of octyl esters, 0.8 parts of diethylene glycol, 0.5 parts of anti-wear agent SI-69, 1 part of zinc oxide, 0.2 parts of ST-stearic acid, 0.15 parts of SP-antiaging agent, 2 parts of PEG-40000, 0.1 parts of dibutyl hydroxytoluene parts, leveling agent AG-2020.5 parts, anti-cracking agent 0.2 parts, EPDM3168 parts.

[0073] The remaining parts are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0075] The difference between this embodiment and embodiment 1 is:

[0076] In the step (1), the rubber for shoe shells is prepared using the following formula: 8 parts of SBR-1502 butadiene rubber, 12 parts of BR-9000 butadiene rubber, 14 parts of 3L natural rubber, 12 parts of white carbon black, dioxalic acid 6 parts of octyl esters, 0.3 parts of diethylene glycol, 0.2 parts of anti-wear agent SI-69, 3 parts of zinc oxide, 0.6 parts of ST-stearic acid, 0.10 parts of SP-antiaging agent, 0.5 parts of PEG-40000, 0.3 parts of dibutyl hydroxytoluene parts, leveling agent AG-202 1.5 parts, anti-cracking agent 0.1 parts, EPDM3163 parts.

[0077] The remaining parts are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com